A comprehensive utilization method of silicate minerals

A silicate and mineral technology, applied in the field of comprehensive utilization of non-metallic ore and hydrometallurgy, can solve the problems of not providing, not meeting spray drying, and not being able to prepare high-purity iron oxide red products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

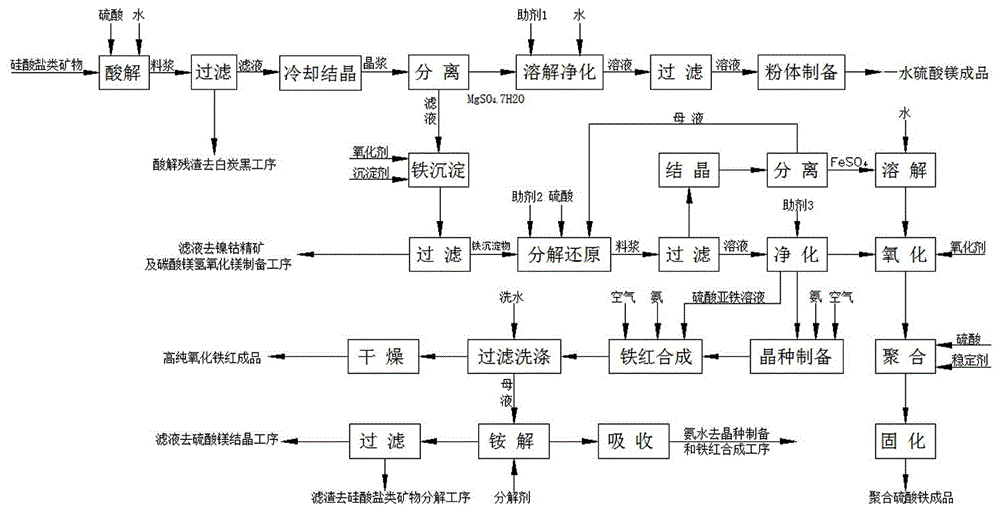

Image

Examples

Embodiment 1

[0109] Such as figure 1As shown, the comprehensive utilization method of the silicate minerals, the processed ore is Sichuan Ya'an asbestos tailings, chemical composition: MgO: 35.74%, Fe 2 o 3 : 6.22%, SiO 2 : 41.81%, NiO: 0.37%, CoO: 0.031%, follow the steps below:

[0110] (1) Pulverize the asbestos tailings to 120 mesh, weigh 100kg of asbestos tailings powder and the secondary acid hydrolysis solution at a solid-to-liquid ratio of 1:2.5 (secondary acid hydrolysis solution 250L) and mix them in the primary acid hydrolysis reactor, After stirring evenly, add 1 kg of activator fluorite, then raise the temperature and add sulfuric acid, control the reaction temperature to 80°C, keep the reaction for 60 minutes, and control the end point pH value to 1. After the reaction was finished, 139kg of the first-level acidolysis residue (50.5% water content, 68.8kg in dry form) and 255L of the first-level acidolysis solution were obtained by filtration. MgSO in primary acid hydrolys...

Embodiment 2

[0125] The raw ore processed is asbestos tailings in Ya'an, Sichuan, chemical composition: SiO 2 : 41.81%, MgO: 35.74%, Fe 2 o 3 : 6.22%, NiO: 0.37%, CoO: 0.031%. Follow the steps below:

[0126] (1) Pulverize the asbestos tailings to 120 mesh, weigh 100kg of asbestos tailings powder and the secondary acid hydrolysis solution at a solid-to-liquid ratio of 1:5 (secondary acid hydrolysis solution 500L) and mix them in the primary acid hydrolysis reactor, After stirring evenly, add 1 kg of activator industrial calcium fluoride, then raise the temperature and add sulfuric acid, control the reaction temperature to 75°C, keep the reaction for 90 minutes, and control the end point pH value to 1. After the reaction was completed, 120 kg of the primary acidolysis residue (49.5% water content, 60.6 kg in dry form) and 500 L of the primary acidolysis solution were obtained by filtration. MgSO in primary acid hydrolysis solution 4 Concentration 213g / l, FeSO 4 The concentration was 2...

Embodiment 3

[0141] The raw ore processed is Serpentine Mine in Inner Mongolia Sunite Left Banner, chemical composition: MgO: 37.81%, SiO 2 : 36%, Fe 2 o 3 : 5.93%, Ni: 0.20%, Co: 0.009%.

[0142] (1) Crush the serpentine to 100 mesh, weigh 100kg of serpentine ore powder and the secondary acid hydrolysis solution at a solid-to-liquid ratio of 1:2.5 (secondary acid hydrolysis solution 250L) and mix them in the primary acid hydrolysis reactor , after stirring evenly, add 1kg of activator, then raise the temperature and add sulfuric acid, control the reaction temperature to 85°C, keep the reaction for 60min, and control the end point pH value to 1.2. After the reaction was completed, 174 kg of the primary acidolysis residue (50.5% water content, 86 kg in dry form) and 262 L of the primary acidolysis solution were obtained by filtration. MgSO in primary acid hydrolysis solution 4 Concentration 432g / l, FeSO 4 The concentration was 42.7 g / l.

[0143] Mix the primary acidolysis residue and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com