A kind of preparation method of multifunctional composite microsphere

A composite microsphere and multifunctional technology, which is applied in the field of preparation of magneto-optical-high specific surface area multifunctional composite microsphere carrier materials, can solve the problems of reducing the magnetic responsiveness of the material, occupying the drug space, and making the combination more difficult. , to achieve the effect of ensuring superparamagnetism, increasing specific surface area and inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

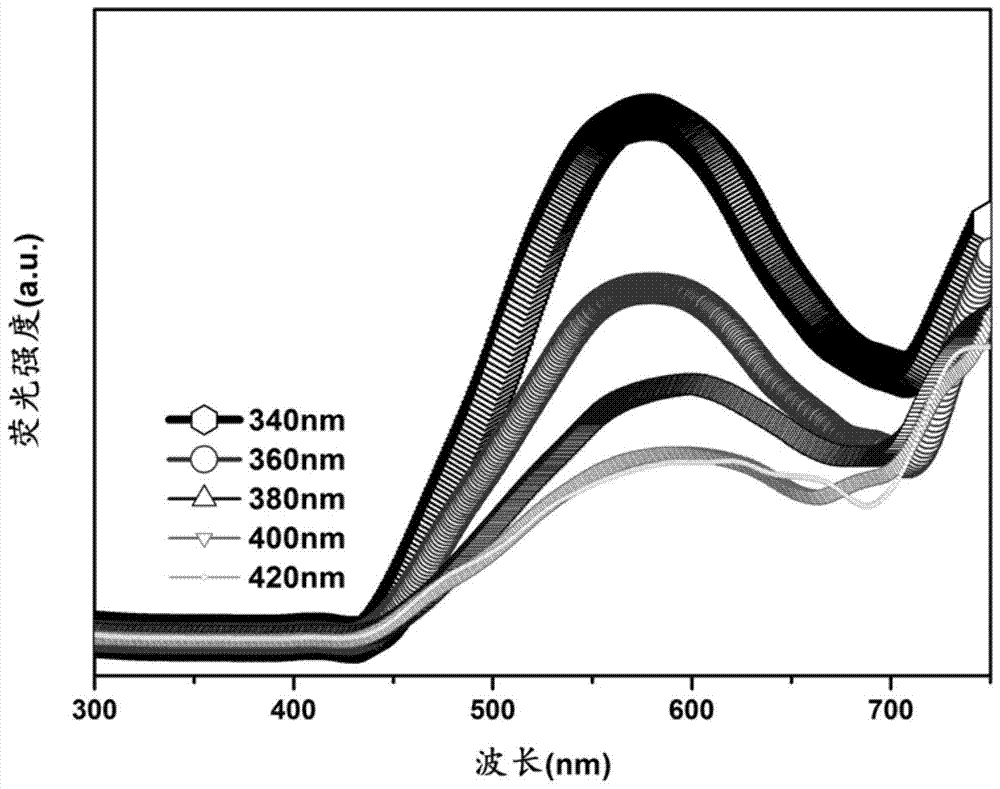

[0032] Step (1) synchronous synthesis of functionalized-Fe 3 o 4 microsphere substrate and carbon quantum dots,

[0033] Dissolve 1.35g of ferric chloride hexahydrate in 70mL of ethylene glycol. After the dissolution is complete, add 3.85g of ammonium acetate and stir evenly. After reacting at -220°C for 10-14 hours, cool down to room temperature naturally. Centrifuge to take the supernatant A and the lower precipitate B respectively; A is purified by dialysis, and freeze-dried for 48 hours to obtain functionalized small particles of carbon quantum dots, which are dispersed in ethanol and configured as solution C with a concentration of 40mg / L, and stored at 4°C Standby; B was washed three times with deionized water and absolute ethanol respectively, and vacuum-dried at 60° C. for 8-12 hours to prepare functionalized magnetic microspheres D.

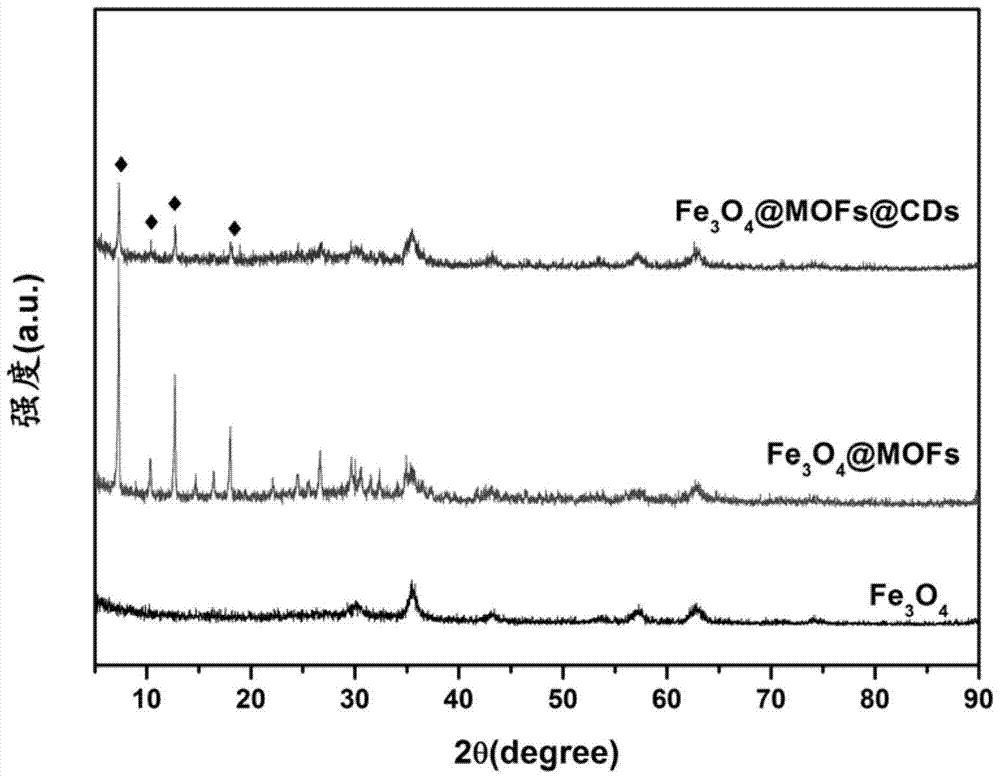

[0034] Step (2) Synthesis of MOFs coated with functionalized-Fe 3 o 4 core-shell microspheres

[0035] Ultrasonic disperse 100mg ...

Embodiment 2

[0041] On the basis of Example 1: the optimum mass ratio of natural high molecular polymer and ferric chloride hexahydrate is selected as 1:2.

[0042] The low content of natural polymers leads to incomplete functionalization, and the content of synchronously synthesized carbon quantum dots is small; the high content of natural polymers will lead to poor magnetic separation effect, and there will be morphology crossover caused by excessive introduction of polymers. In combination, the required particle size of the drug carrier is not uniform and the shape is poor.

Embodiment 3

[0044] On the basis of Example 2: the hydrothermal temperature is selected as 200° C., and the reaction is carried out for 12 hours. The control of temperature and reaction time parameters can further improve the particle size uniformity of the drug carrier. The best polydispersity index of the product can reach 0.154-0.332, indicating that the particle size distribution of the product is narrow and the dispersibility is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com