Pre-treatment method of cotton or polyester-cotton blended fabric

A polyester-cotton blended and fabric technology, which is applied in the directions of enzyme/microorganism biochemical treatment, fiber treatment, biochemical fiber treatment, etc., can solve the problems of not meeting the requirements of wettability, difficult to remove impurities, and high COD value, reducing water washing. The number of times, the saving of dye consumption, the effect of improving the depth of dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Trametes CGMCCNo.10489 fermentation crude enzyme liquid

[0041] Weigh 200g of peeled potatoes, cut into small pieces, add 1.0L of water and boil for 30min, filter through 4 layers of gauze to remove the potato pieces, make up the filtrate to 1.0L, add 20.0g of glucose, and add 1g of lignosulfonate. After subpackaging, sterilize under high pressure at 121°C for 20 minutes, cool down, perform aseptic operation, insert the bacterial suspension of the trametessp.LEF01 strain that has been cultured on the PDA slant medium for 5 to 6 days, and place it in a constant temperature shaking incubator at 28°C. The culture was shaken for 6 days at a rotation speed of 150 rpm. After the fermentation was completed, the fermentation broth was centrifuged at 4000 rpm for 30 minutes, and the obtained supernatant was crude enzyme liquid.

[0042] In the obtained crude enzyme liquid, the activity of laccase was 4100.8U / L, the activity of cellulase was 2310U / L, the activity o...

Embodiment 2

[0043] Embodiment 2: mixed flora produces crude enzyme liquid

[0044] Cultivate the mixed flora on the broth medium to prepare the seed liquid, and then inoculate it in the broth medium containing 4-6g / L 1,3-butanediol, in the induction of 1,3-butanediol Fermented at 30°C for 3 days to produce enzyme, then collected the cells, broken the wall, and centrifuged to get the supernatant to measure the enzyme activity.

[0045] The broth medium contains 10.0-15.0 g / L of peptone, 3.0-5.0 g / L of beef powder, 5.0-6.0 g / L of sodium chloride, 4-6 g / L of 1,3-butanediol, and pH7. 2±0.2.

[0046] The results showed that the activity of PVA degrading enzyme in the crude enzyme liquid could reach 1.985U / mL.

Embodiment 3

[0047] Example 3: Pre-treatment of fabrics in cold pile method based on compound enzyme solution

[0048] (1) cold pile method:

[0049] ① Fabric: T / C(65 / 35)94cm13×13523.5×283

[0050] ②Technical process: gray cloth → padding compound enzyme solution (padding temperature 30°C-50°C, liquid retention rate 80%-100%) → stacking (30°C-50°C stacking 4-6h) → 80°C-95 ℃ hot water washing→hydrogen peroxide bleaching (90℃-95℃ stacking for 30-45min)→water washing.

[0051] ③Compound enzyme solution formula:

[0052] Trametes fermented crude enzyme liquid 2.5g / L

[0053] Mixed strain fermented crude enzyme liquid 40g / L

[0054] Amylase 2.5g / L

[0055] Non-ionic wetting agent 5g / L

[0056] pH 7

[0057] ④Oxygen bleaching formula

[0058] Sodium silicate 1.5g / L

[0059] Hydrogen peroxide (27.5%) 12g / L

[0060] Stabilizer 1.5g / L

[0061] Sodium hydroxide (30%) 5mL / L

[0062] Chelating dispersant 1mL / L

[0063] Scouring agent 2g / L

[0064] pH 10

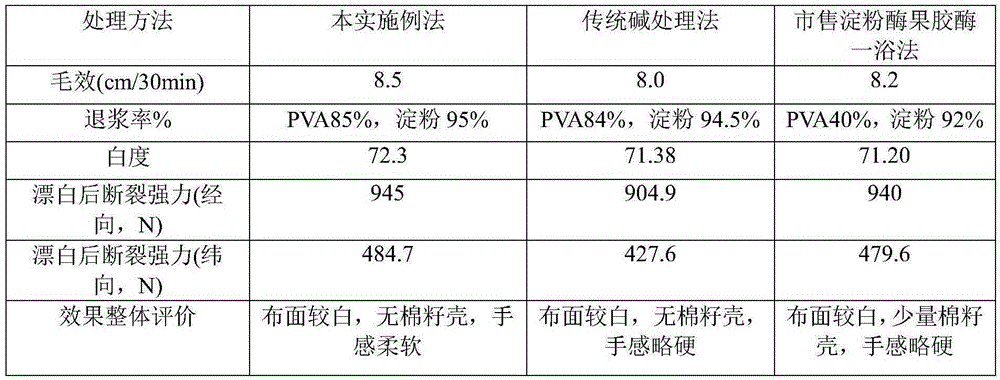

[0065] ⑤ The treatment effect i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com