Industrial waste cracking incineration exhaust gas denitration system

A technology for industrial waste and exhaust gas, which is applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of reducing treatment efficiency, equipment wear, investment and operating costs, and achieves improved conversion efficiency, low long-term operation, The effect of improving processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

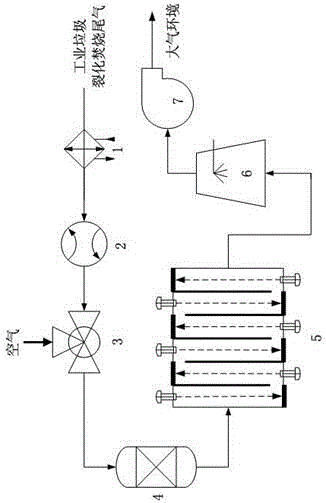

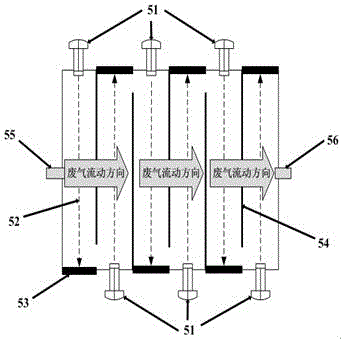

[0022] Such as figure 1 The industrial waste cracking and incineration tail gas denitrification system shown, the system includes a gas overheating protector 1, a thermal gas mass flow meter 2, a mixed gas flow regulating valve 3, a bag filter 4, and a diode-pumped rubidium steam laser array decomposition reactor 5. Flue gas cooling system 6, exhaust fan 7; among them, industrial waste cracking and incineration exhaust gas enters the gas overheating protector 1 through the gas pipeline, and the outlet of the gas overheating protector 1 is connected to the thermal gas mass flow meter 2 through the gas pipeline , the outlet of the thermal gas mass flowmeter 2 is connected to the mixed gas flow regulating valve 3 through the gas pipeline, the outlet of the mixed gas flow regulating valve 3 is connected to the bag filter 4 through the gas pipeline, and the outlet of the bag filter 4 is connected to the gas pipeline Connect the inlet valve on the left side wall of semiconductor pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com