Low-temperature-resistant methanogen enrichment culture method and application thereof

A technology of enrichment culture and methanogenic bacteria, which is applied in the direction of using microorganisms, waste fuels, fermentation, etc., can solve the problems of high time cost and economic cost of bacterial agents, decreased biogas fermentation effect, and long time required, etc., to achieve Low temperature application Wide temperature range, few steps and short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment 1: The method for enrichment and cultivation of low-temperature-resistant methanogens of this embodiment is carried out according to the following steps:

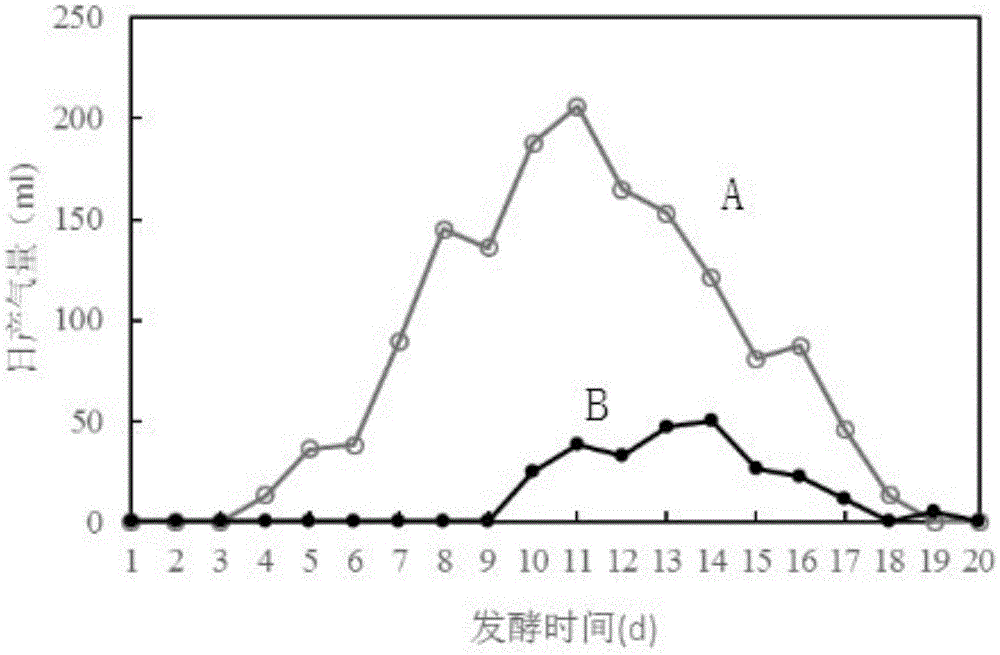

[0019] Take the activated sludge and break it, put it into the enrichment medium, and conduct the enrichment culture under the condition of the enrichment culture temperature of 15~25℃; when it is detected that the enrichment culture system generates bubbles, pass the control The temperature system gradually lowers the temperature until no bubbles are detected, and the temperature is stopped to complete the enrichment culture of low-temperature resistant methanogens.

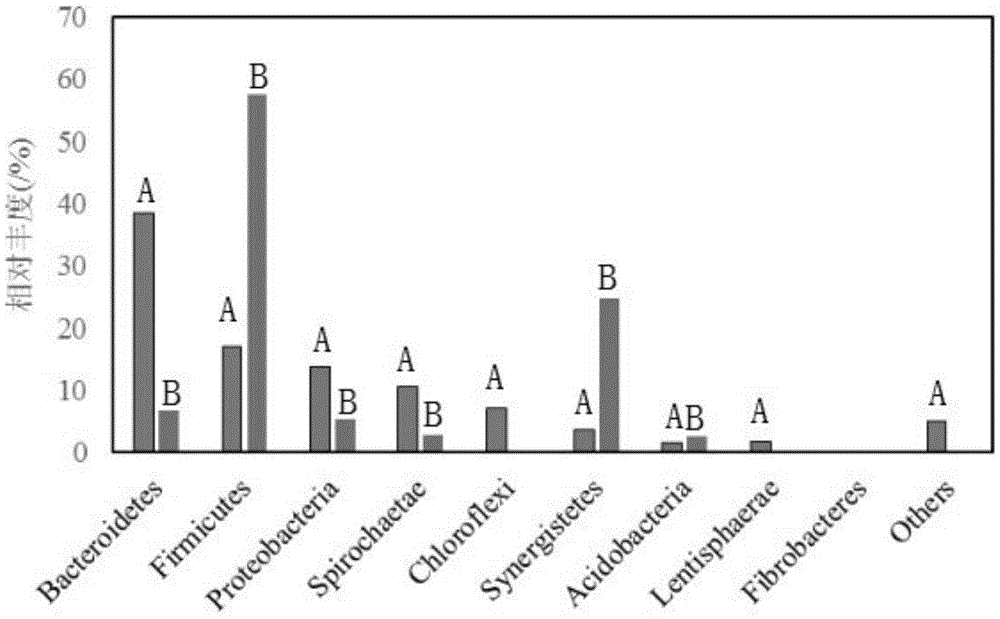

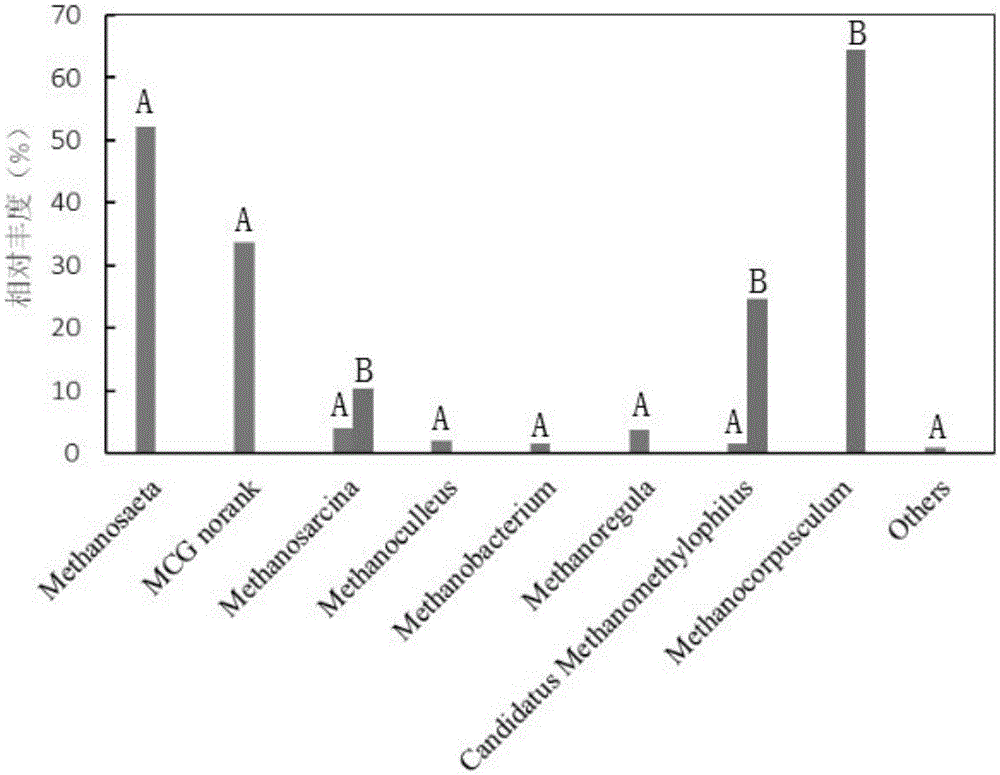

[0020] The present invention finds that the bacteria before and after enrichment are mainly Bacteroidetes, Firmicutes, Proteobacteria, Spirochaete, and Chloroflexus by analyzing the structure of the bacteria before and after enrichment. (Chloroflexi), Synergistetes, Acidobacteria, Lentisphaerae and Fibrobacteres. After enrichment of met...

specific Embodiment approach 2

[0021] Specific embodiment two: this embodiment is different from specific embodiment one in that the activated sludge is a natural habitat wetland sludge, activated sludge from a sewage treatment plant or livestock and poultry manure, and a mixture of biogas slurry and biogas residue. Others are the same as the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: This embodiment is different from the specific embodiment one in that the components of the enrichment medium contain 0.5 g of K per 1L 2 HPO 4 ·3H 2 O, 0.4g / L KH 2 PO 4 , 1g of NH 4 Cl, 0.2g of MgCl 2 ·6H 2 O, 2g of yeast powder, 2g of peptone, 5g of sodium formate, 8.3g of sodium acetate, 3mL of methanol, 0.5g of cysteine, 1ml of vitamin solution and 1ml of trace element solution; pH value is 6.8-7.2 ;

[0023] Wherein, the trace element liquid contains 1.5g of FeCl per 1L 2 , 70mg of ZnCl 2 , 6mg boric acid, 0.1g MnCl 2 ·4H 2 O, 2mg CuCl 2 ·2H 2 O, 0.19g of CoCl 2 ·6H 2 O, 24mg NiCl 2 ·6H 2 O, 36mg of Na 2 MO 4 ·H 2 O, 15mg of Na 2 WO 4 ·2H 2 O and 15mg of Na 2 SeO 4 ·5H 2 O composition;

[0024] The vitamin solution contains 50.0 mg of lipoic acid, 20.0 mg of biotin, 0.35 g of niacin, 5.0 mg of thiamine hydrochloride, 50.0 mg of para-aminobenzoic acid, 20.0 mg of folic acid, and 50.0 mg of pantothenic acid per 1L. Calcium, 1.0mg of vitamin B 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com