A three-in-one dry powder coating for interior walls

A dry powder and coating technology, applied in powder coatings, fireproof coatings, rosin coatings, etc., can solve the cost of tens of thousands, even tens of thousands, hundreds of thousands, quality problems and hidden dangers of engineering decoration, decoration materials and cost increases Advanced problems, to achieve the effect of improving mechanical strength, solving compatibility and processing problems, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

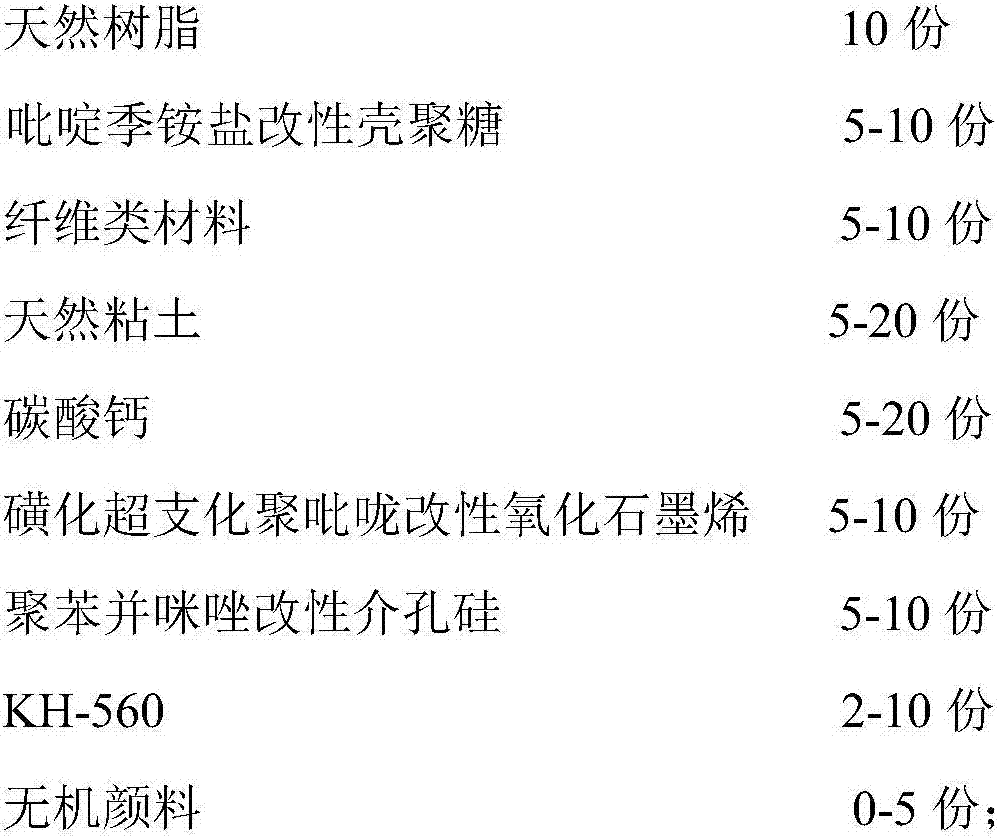

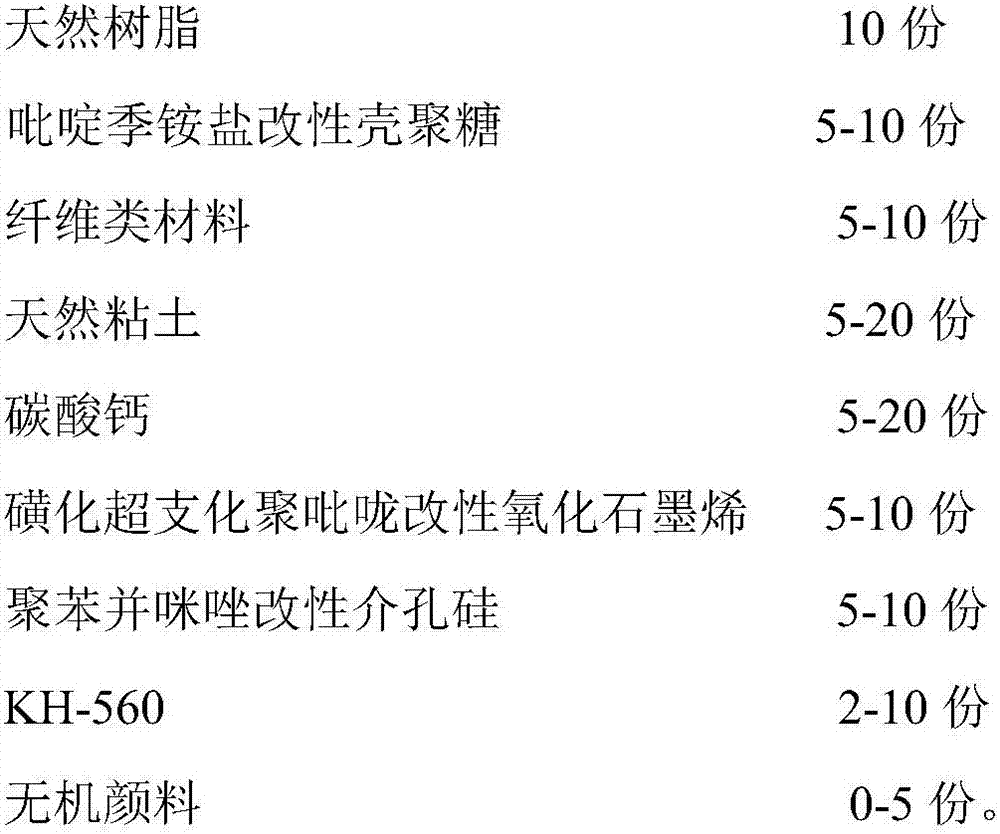

Method used

Image

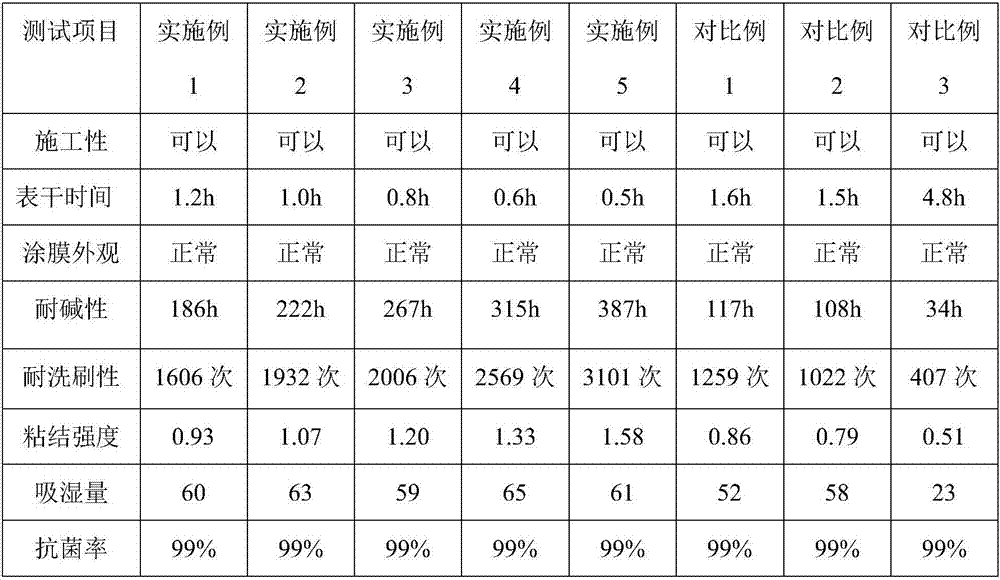

Examples

preparation example Construction

[0047] B1: chitosan modified by pyridinium quaternary ammonium salt, prepared by the following method:

[0048] (1) Preparation of epoxypyridinium quaternary ammonium salt

[0049] Add 1 mole of epichlorohydrin and 1 mole of pyridine into a completely dry three-necked flask, react at 50°C for 24 hours, filter with suction, and wash the solid product with acetone three times, then dry it in a vacuum oven at 50°C 22h, to obtain epoxypyridinium quaternary ammonium salt;

[0050] (2) Preparation of pyridine quaternary ammonium salt modified chitosan

[0051] In a 100ml three-necked bottle, add 0.1 mole of chitosan and 0.1 mole of the epoxypyridinium quaternary ammonium salt synthesized above, and stir evenly at room temperature; after weighing 0.1 mole of sodium hydroxide and dissolving it in water, add it to the above mixture, After reacting at 60° C. for 10 hours, neutralize with acetic acid and wash repeatedly with ethanol, filter with suction and dry to obtain the chitosan m...

Embodiment 1

[0101] In parts by weight, add 10 parts of A1, 8 parts of B1, 7 parts of C1, 8 parts of F1, 7 parts of G1, 8 parts of H1 and 0.1 part of I1 into the mixer and mix them thoroughly for 10 minutes. Add 15 parts of D1 and 15 parts of E1 continued to mix for 5 minutes and discharged. Stir evenly according to the ratio of powder to water of 1:0.5, and it can be used according to the weight ratio.

Embodiment 2

[0103] In parts by weight, add 10 parts of A1, 8 parts of B1, 7 parts of C1, 8 parts of F2, 7 parts of G2, 8 parts of H1 and 0.1 part of I1 into the mixer and mix thoroughly for 10 minutes, add 15 parts of D1 and 15 parts of E1 continued to mix for 5 minutes and discharged. Stir evenly according to the ratio of powder to water of 1:0.5, and it can be used according to the weight ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alkali resistance | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com