All-water foaming cold-cure foam fireproof sealant and preparation method thereof

A technology of all-water foaming and caulking adhesive, which is applied in the fields of adhesives, polyurea/polyurethane adhesives, plastic recycling, etc., and can solve problems such as demanding reaction temperature, difficulty in cold-aging polyurethane, and difficulty in long-term storage , to achieve the effects of improving construction efficiency, excellent flame retardancy, and solving poor hydrolytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

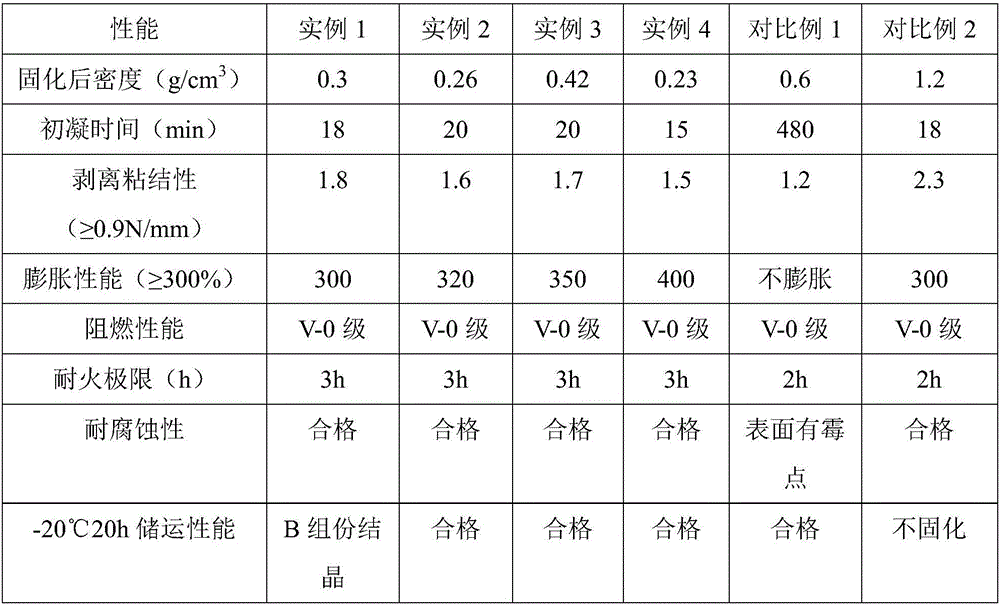

Examples

Embodiment 1

[0026] 15 parts of trihydroxypolyoxypropylene ether with a hydroxyl value of 336mgKOH / g, 85 parts of dihydroxypolyoxypropylene ether with a hydroxyl value of 112mgKOH / g, 50 parts of dimethyl methylphosphonate, 0.4 parts of highly active silicone oil, and 2.9 parts of deionized water , 2 parts of diethanolamine, 2.76 parts of 2-aminoethanol, 2 parts of 1,8-diazabicycloundec-7-ene phenoxide, 0.5 parts of triethylenediamine, 25 parts of expandable graphite, 2 parts of iron red 20 parts of aluminum hydroxide, 5 parts of zinc borate, 40 parts of type II ammonium polyphosphate, 15 parts of melamine, 12 parts of pentaerythritol, 1.2 parts of γ-aminopropyltriethoxysilane, carbodiimide modified di 47 parts of phenylmethane diisocyanate, 45 parts of polymethylene polyphenyl polyisocyanate.

[0027] The preparation method of the intumescent fireproof sealant is as follows: trihydroxy polyoxypropylene ether, dihydroxy polyoxypropylene ether, dimethyl methyl phosphonate, highly active sili...

Embodiment 2

[0029] 90 parts of trihydroxypolyoxypropylene ethers with a hydroxyl value of 37 mgKOH / g, 10 parts of polymer grafted polyols with a hydroxyl value of 28 mgKOH / g, 38 parts of tris (β-chloroethyl) phosphate, 0.5 parts of highly active silicone oil, and 3.5 parts of ionized water, 1.8 parts of ethylene glycol, 8.47 parts of aminopropanol, 2.2 parts of 1,8-diazabicycloundec-7-ene octanoate, 0.9 parts of bis(dimethylaminoethyl)ether , 30 parts of expandable graphite, 5 parts of iron red, 10 parts of magnesium hydroxide, 5 parts of ammonium octamolybdate, 45 parts of type II ammonium polyphosphate, 10 parts of melamine urate, 10 parts of dipentaerythritol, γ-aminopropanol 0.8 parts of trimethoxysilane, 84 parts of carbodiimide-modified diphenylmethane diisocyanate, and 32.5 parts of 3-isocyanatomethylene-3,5,5-trimethylcyclohexyl isocyanate.

[0030] The preparation method of the intumescent fireproof sealant is as follows: trihydroxypolyoxypropylene ether, polymer grafted polyol, ...

Embodiment 3

[0032]30 parts of trihydroxypolyoxypropylene ether with a hydroxyl value of 168 mgKOH / g, 70 parts of polycaprolactone diol with a hydroxyl value of 56 mgKOH / g, 44 parts of tris(β-chloropropyl) phosphate, 0.6 parts of highly active silicone oil, 1.8 parts of deionized water, 2 parts of hexanediol, 0.5 parts of 2-methylpentamethylenediamine, 6.88 parts of aminobutanol, 1.8 parts of 1,8-diazabicycloundec-7-ene octanoate, 1.5 parts of N,N-dimethylethanolamine, 35 parts of expandable graphite, 3.530 parts of iron red, 15 parts of magnesium hydroxide, 5 parts of aluminum hydroxide, 6 parts of zinc borate, 8 parts of ammonium octamolybdate, type II polymer 30 parts of ammonium phosphate, 8 parts of melamine, 3 parts of dipentaerythritol, 1.8 parts of phytanic acid monoalkoxy titanate, 57 parts of polymethylene polyphenyl polyisocyanate, 3-isocyanate methylene-3 , 7 parts of 5,5-trimethylcyclohexyl isocyanate.

[0033] The preparation method of the intumescent fireproof sealant is as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com