Porous carbon doped silver nanoparticles capable of visually and rapidly detecting mercury ions

A technology of silver nanoparticles and porous carbon, which is applied in the field of doped porous carbon silver nanoparticles and porous carbon doped silver nanoparticles, can solve the problems of complex preparation, high selectivity, instability, etc., and achieve simple and dispersed preparation methods. Good stability and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Preparation of doped porous carbon silver nanoparticles for rapid detection of mercury ions according to the present invention.

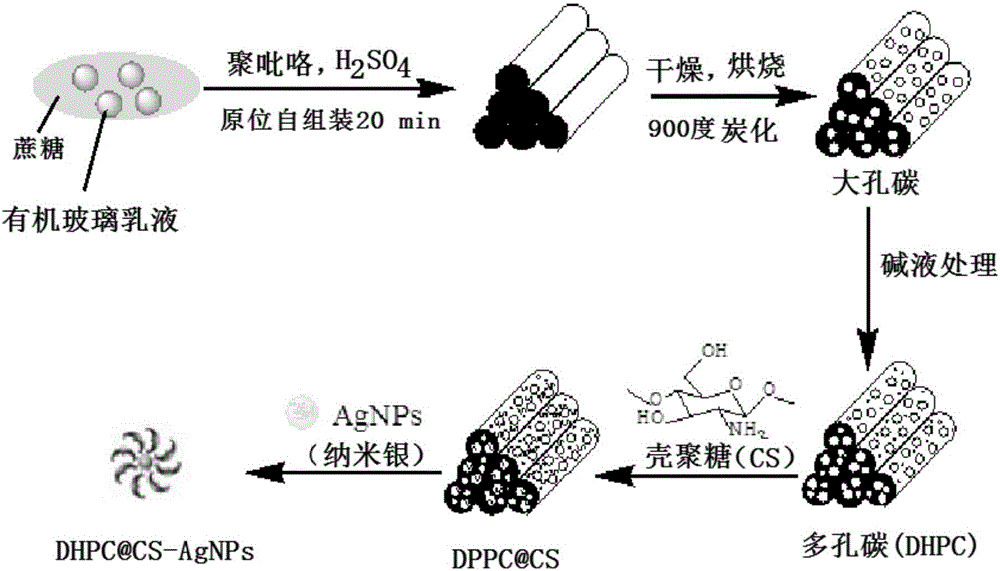

[0022] The principle diagram of the preparation of the doped porous carbon-silver nanoparticles for rapid detection of mercury ions described in this example is as follows figure 1 Shown, preparation method comprises the following steps:

[0023] (1) Add 100mL of deionized water, 20mL of methyl methacrylate and 0.04g of potassium persulfate into a 250mL three-necked flask in sequence, turn on the cooling water, pass nitrogen, and react in a water bath at 90°C for 1 hour under mechanical stirring at 350r / min. A polymethyl methacrylate emulsion (PMMA) is obtained. (2) Add 0.5g sucrose and 0.1g polypyrrole in turn to 20g PMMA emulsion, stir mechanically at 350r / min for 15min, then add 1mL 0.5mol / L H 2 SO 4 , in situ self-assembly reaction for 15 min. The resulting product was poured into a petri dish and dried in a drying oven ...

Embodiment 2

[0024] Embodiment 2: Preparation of doped porous carbon silver nanoparticles for rapid detection of mercury ions according to the present invention.

[0025] The principle diagram of the preparation of the doped porous carbon-silver nanoparticles for rapid detection of mercury ions described in this example is as follows figure 1 Shown, preparation method comprises the following steps:

[0026] (1) Add 120mL of deionized water, 20mL of methyl methacrylate and 0.08g of potassium persulfate to a 250mL three-necked flask in sequence, turn on the cooling water, pass nitrogen, and react in a water bath at 90°C for 2 hours under mechanical stirring at 500r / min. A polymethyl methacrylate emulsion (PMMA) is obtained. (2) Add 0.75 g of sucrose and 0.15 g of polypyrrole to 30 g of PMMA emulsion in turn, stir mechanically at 350 r / min for 20 min, then add 1 mL of 1.0 mol / L H 2 SO 4 , in situ self-assembly reaction for 20min. The resulting product was poured into a petri dish and drie...

Embodiment 3

[0027] Example 3: Porosity of porous carbon (DHPC) nanoparticles according to the present invention.

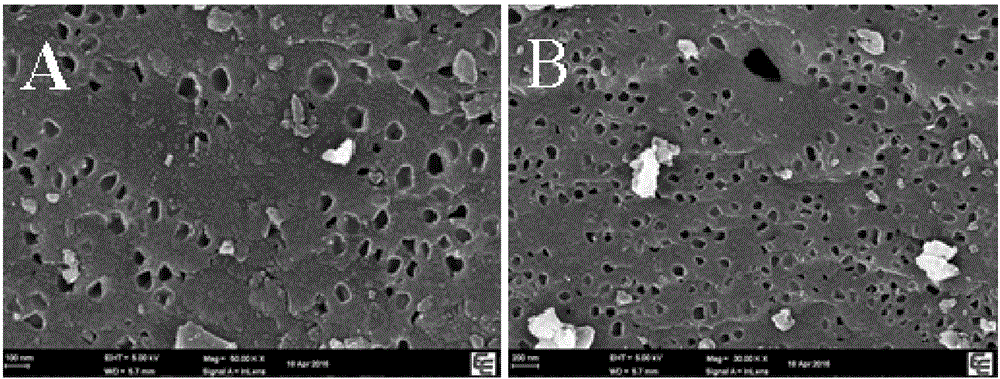

[0028] SEM detection: the porous carbon (DHPC) nanoparticles prepared in Example 1 were observed by SEM, as figure 2 As shown, the prepared macroporous carbon ( figure 2 A) the pore size is relatively large, and the pore distribution is even; the porous carbon obtained after lye activation treatment ( figure 2 B) The surface is smooth, the pore diameter is obviously smaller, there are macropores, micropores and mesopores, mainly micropores, and the specific surface area is large. The calculated BET surface area is 840cm 2 / g, the total pore volume is 2.1cm 3 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com