Preparation method of rhodium-ruthenium composite catalyst for preparing ethyl alcohol through acetic acid hydrogenation

A composite catalyst, a technology for hydrogen preparation, applied in catalyst activation/preparation, preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of low conversion rate and selectivity, and achieve high conversion rate and selectivity of ethanol. Good effect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

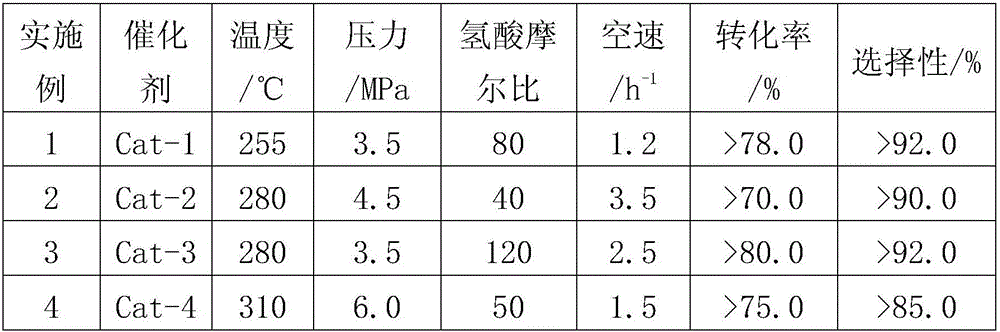

Examples

Embodiment 1

[0041]Weigh 1 g of rhodium(III) chloride hydrate, 0.5 g of anhydrous ruthenium trichloride, and 0.5 g of cobalt nitrate hexahydrate, and prepare 100 mL of an aqueous solution of the metal salt in a volumetric flask. Add ammonia water with a concentration of 25-28% to the aqueous solution of the metal salt at 50°C until the final pH value is 7.5; add 20g of γ-alumina to the solution and continue stirring for 4 hours to make the precipitate adsorb on the carrier γ-tri On aluminum oxide, the quasi-catalyst was obtained; then the quasi-catalyst was filtered to remove impurities therein, washed with water, and dried at 100°C for 12 hours to obtain the catalyst; the catalyst was taken out and roasted in a muffle furnace, from room temperature to The temperature was raised to 400°C at a rate of 5°C / min, kept for 4 hours for calcination, and then slowly lowered to room temperature. The prepared catalyst is called Cat-1.

Embodiment 2

[0043] Weigh 1.0 g of rhodium (II) acetate dimer, 0.8 g of ruthenium acetate, 2.0 g of molybdenum acetate, and 2.0 g of nickel nitrate in a volumetric flask to make 1 L of metal salt aqueous solution, and place it in a large beaker. Add 0.10 mol / L sodium hydroxide aqueous solution to the aqueous solution of metal salt under the environment of 80 ℃ until the end point pH value is 6.5; catalyst; then the quasi-catalyst was filtered to remove impurities therein, washed with water, and dried at 120°C for 8 hours to obtain the catalyst; the catalyst was taken out and roasted in a muffle furnace, and the temperature was raised from room temperature at a rate of 5°C / min to 550 ° C, and keep 8h roasting, and then slowly cool down to room temperature. The prepared catalyst is called Cat-2.

Embodiment 3

[0045] Weigh 0.5g of rhodium(III) chloride hydrate, 1.0g of anhydrous ruthenium trichloride, and 2.0g of manganese acetate tetrahydrate into a 1000mL volumetric flask to prepare a metal salt solution. Add 1.0mol / L sodium carbonate aqueous solution to the aqueous solution of the metal salt at 60°C until the final pH value is 8.0; add 50g of ceria to the solution and continue to stir for 6 hours to make the precipitate adsorb on the carrier ceria , to obtain the quasi-catalyst; then the quasi-catalyst was filtered to remove impurities therein, washed with water, and dried in a dry environment at 120°C for 10 hours to obtain the catalyst; the catalyst was taken out and roasted in a muffle furnace, from room temperature at 5°C / min The temperature was raised to 650°C and kept for 10h for calcination; then the temperature was slowly lowered to room temperature to obtain the desired titanium dioxide-supported catalyst called Cat-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com