Silicon nitride whisker combined silicon carbide porous ceramic and production method thereof

A technology of silicon nitride whiskers and porous ceramics, applied in the field of porous ceramics, can solve the problems of being unsuitable for large-scale production, endangering the health of operators, and causing great harm to people and the environment, achieving low production costs, improving overall performance, and reducing pollution small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

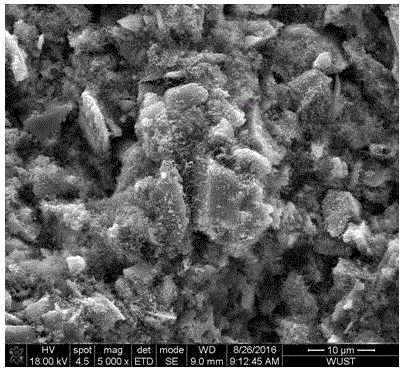

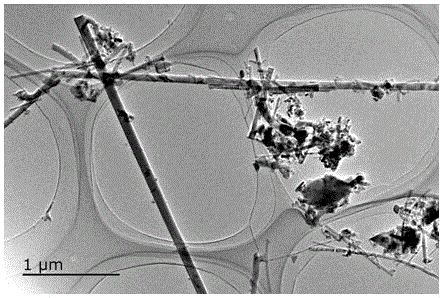

[0038] A silicon nitride whisker-bonded silicon carbide porous ceramic and a preparation method thereof. The steps of the preparation method are:

[0039] Step 1. According to the mass ratio of foam stabilizer: deionized water (0.001-0.005): 1, add the foam stabilizer into the deionized water, and magnetically stir for 12-24 hours to prepare a foam stabilizer solution.

[0040] Step 2, press catalyst: isobutylene-maleic anhydride copolymer: ceramic powder: the mass ratio of described deionized water is (0.001~0.04): (0.01~0.015): (2.34~3.10): 1, catalyst, Isobutylene-maleic anhydride copolymer and ceramic powder are added into the foam stabilizer solution, and mechanically stirred for 5-15 minutes to prepare silicon nitride / silicon carbide ceramic slurry.

[0041] Step 3, according to the foaming agent: the volume ratio of the silicon nitride / silicon carbide ceramic slurry is (0.005~0.01): 1, adding the foaming agent to the silicon nitride / silicon carbide ceramic slurry, Sti...

Embodiment 2

[0046] A silicon nitride whisker-bonded silicon carbide porous ceramic and a preparation method thereof. The steps of the preparation method are:

[0047] Step 1. According to the mass ratio of foam stabilizer: deionized water (0.001-0.005): 1, add the foam stabilizer into the deionized water, and magnetically stir for 12-24 hours to prepare a foam stabilizer solution.

[0048] Step 2, press catalyst: isobutylene-maleic anhydride copolymer: ceramic powder: the mass ratio of described deionized water is (0.04~0.08): (0.004~0.01): (2.26~2.99): 1, catalyst, Isobutylene-maleic anhydride copolymer and ceramic powder are added into the foam stabilizer solution, and mechanically stirred for 5-15 minutes to prepare silicon nitride / silicon carbide ceramic slurry.

[0049] Step 3, according to the foaming agent: the volume ratio of the silicon nitride / silicon carbide ceramic slurry is (0.005~0.01): 1, adding the foaming agent to the silicon nitride / silicon carbide ceramic slurry, Stir...

Embodiment 3

[0054] A silicon nitride whisker-bonded silicon carbide porous ceramic and a preparation method thereof. The steps of the preparation method are:

[0055] Step 1. According to the mass ratio of foam stabilizer: deionized water (0.005-0.01): 1, add the foam stabilizer into the deionized water, and magnetically stir for 12-24 hours to prepare a foam stabilizer solution.

[0056] Step 2, press catalyst: isobutylene-maleic anhydride copolymer: ceramic powder: the mass ratio of described deionized water is (0.001~0.04): (0.004~0.01): (2.19~2.89): 1, catalyst, Isobutylene-maleic anhydride copolymer and ceramic powder are added into the foam stabilizer solution, and mechanically stirred for 5-15 minutes to prepare silicon nitride / silicon carbide ceramic slurry.

[0057] Step 3, according to the foaming agent: the volume ratio of the silicon nitride / silicon carbide ceramic slurry is (0.01~0.02): 1, adding the foaming agent to the silicon nitride / silicon carbide ceramic slurry, Stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com