Process for producing benzophenone ultraviolet ray absorbent

A technology of benzophenones and production process, which is applied in the field of production process of benzophenone ultraviolet absorbers, can solve the problems of potential safety hazards, long reaction time, cumbersome post-processing, etc., and achieve energy saving and Labor costs, reduced consumption of organic solvents, and short time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] 10kg 2,4-dihydroxybenzophenone (UV-0), 10.5kg chlorooctane, 6kg soda ash (99%), 50g polyethylene glycol-400 (99%), 30g potassium bromide (99%) %) into the reaction kettle, start stirring, heat up to 180°C for reflux reaction, heat preservation reaction for 2 hours, add water to stir and wash with water for 30 minutes, let stand for 30 minutes, separate the lower layer of waste water, and transfer the upper layer of product to a high temperature still to be distilled;

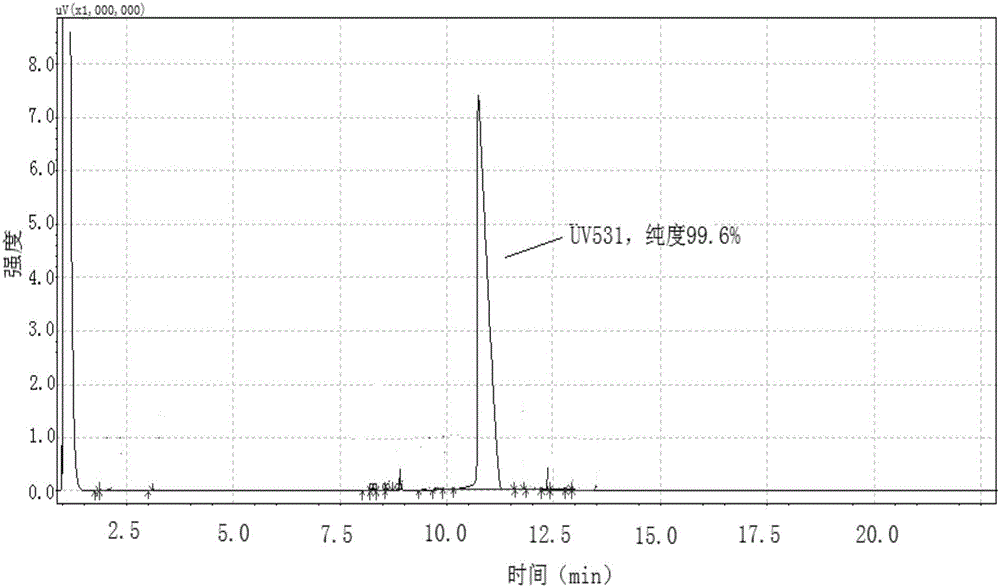

[0070]Put the UV-531 crude product obtained by the above alkylation reaction into a stainless steel still, add 1% 2,6-di-tert-butyl-4-methylphenol (BHT) and 2% tris(2,4-di tert-butylphenyl) phosphite (antioxidant 168), warming up to 65°C, stirring for 1h, and then in 1x10 -2 Heating distillation under pa vacuum condition, before 130℃, the distillate is chlorinated n-octane, which is recovered by secondary condensation (stainless steel condenser, condensation area 20m 2 , primary water cooling +5°C and pr...

Embodiment 2

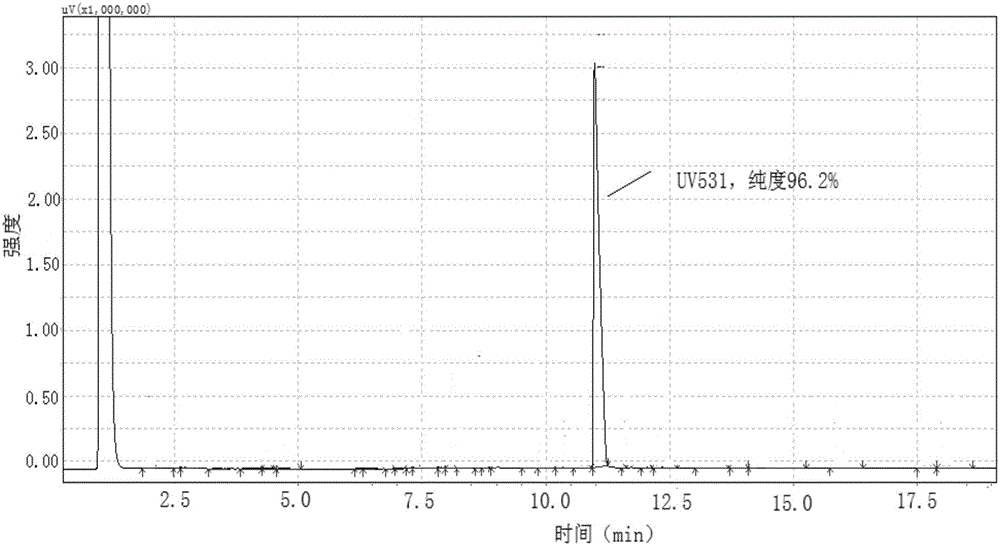

[0073] Put 10kg of n-octanol (99%) and 40g of N,N-dimethylacetamide into the enamel reaction kettle, the pressure inside the kettle is -0.04MPa, heat up to 60°C and keep it warm, slowly drop 11kg of chlorinated chlorinated under the liquid surface After the addition of sulfone and thionyl chloride, keep warm for 3 hours. After the sampling and analysis are qualified, the material is discharged. After washing with water for 3 times, add solid soda ash and water to adjust the pH value to 8. The lower layer of waste water is separated, and the upper layer of chlorooctane is stored. spare tank;

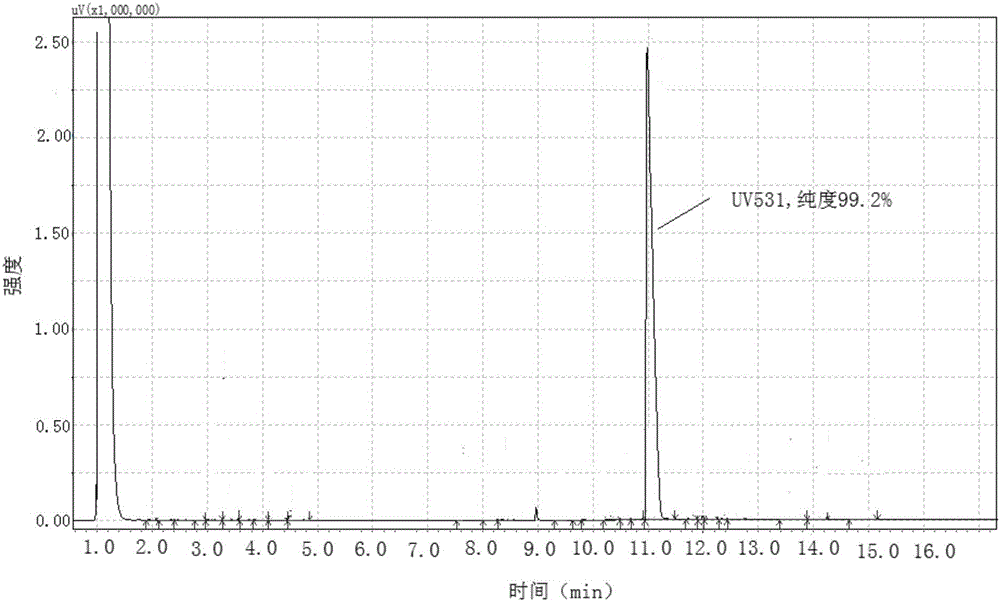

[0074] Put 10kg UV-0, 11kg chlorooctane, 7kg soda ash (99%), 60g alkyltrimethylammonium chloride (99%), and 40g potassium bromide (99%) into the reactor, start stirring, and heat up Reflux reaction at 170°C, keep warm for 2 hours, add water to stir and wash with water for 40 minutes, let stand for 30 minutes, separate the lower layer of wastewater, and transfer the upper layer product to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com