Method for producing cordycepin with self-assembly silicon plastid electrostatic spinning fibrous membrane immobilized cells

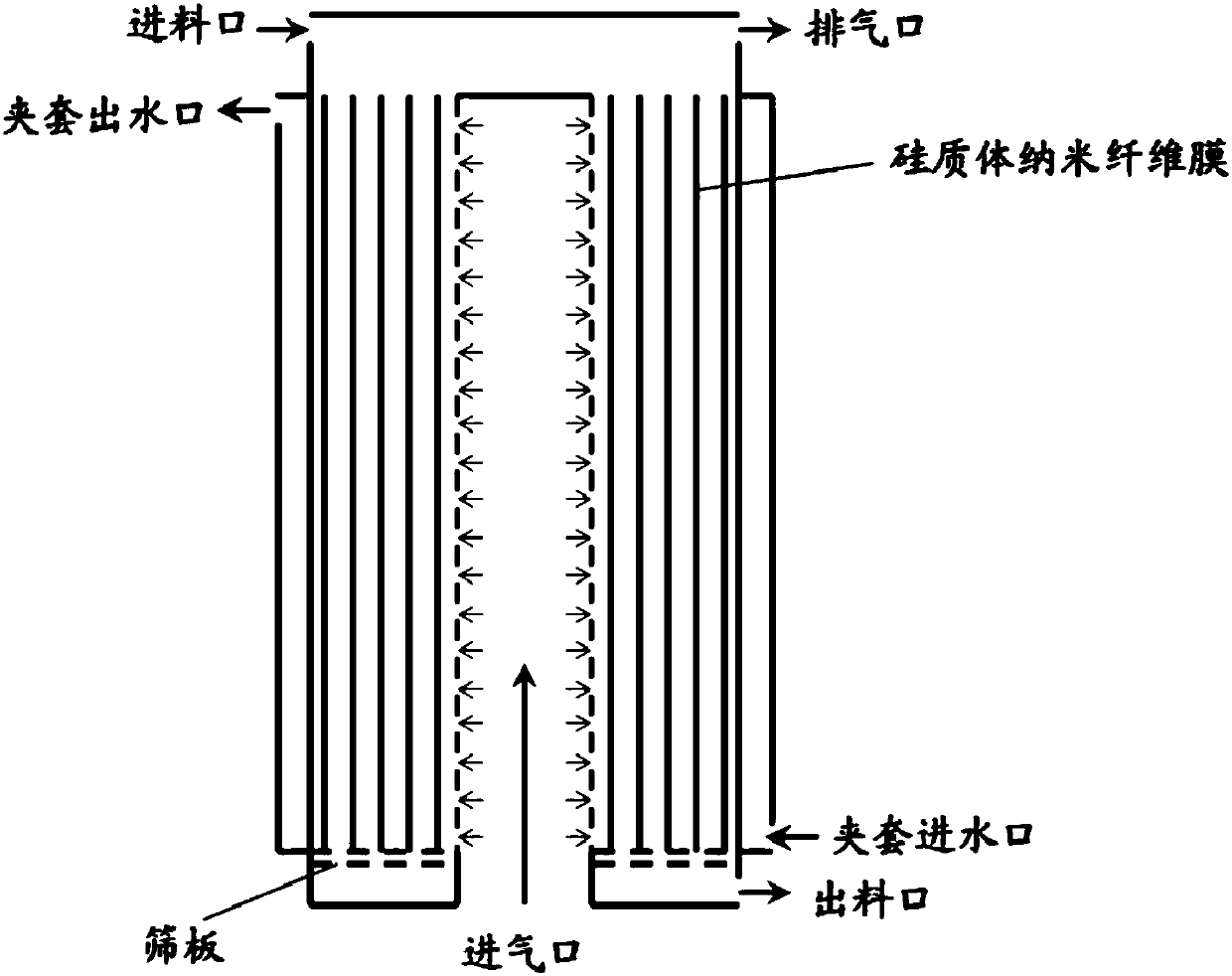

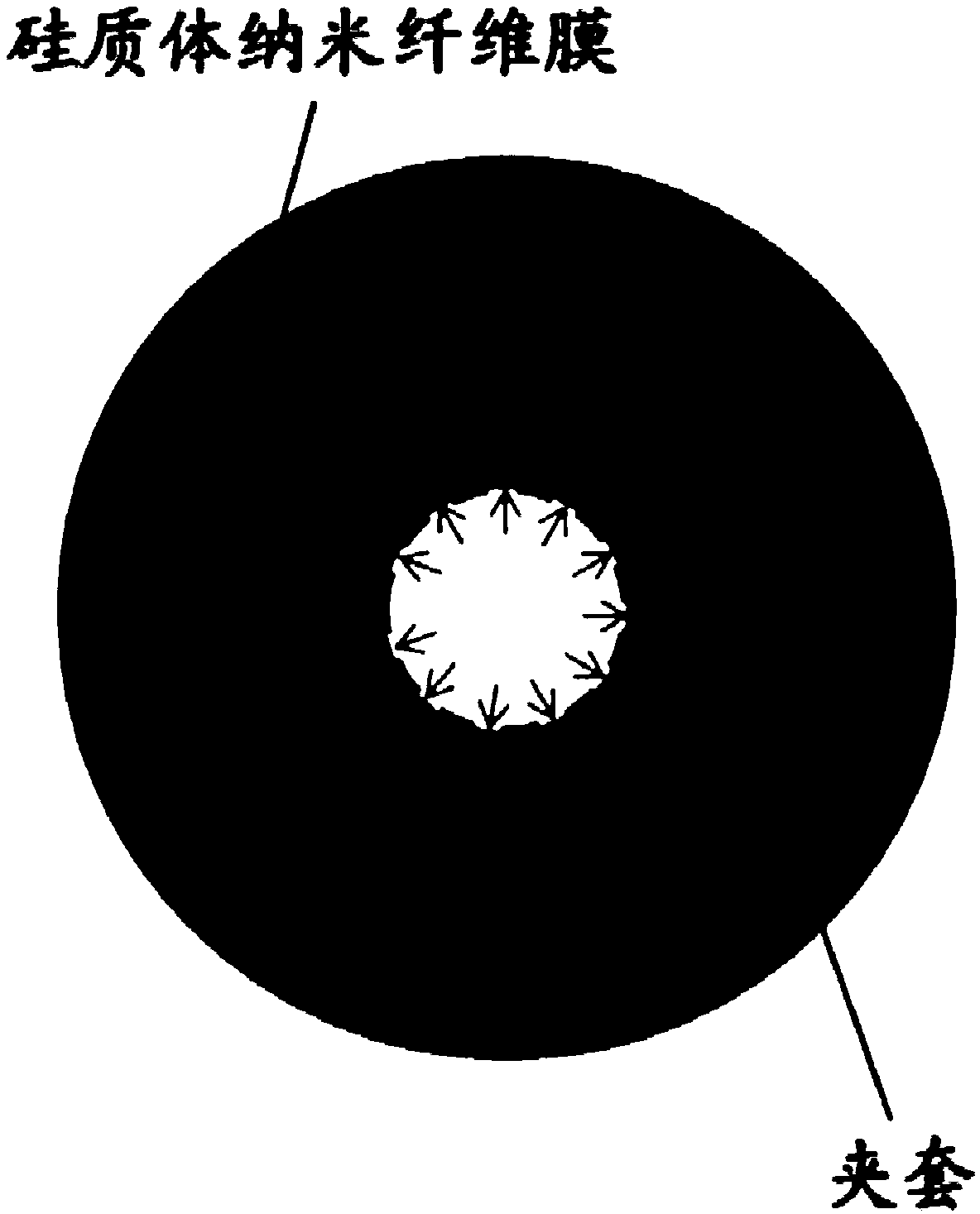

A technology for cell production of cordycepin and electrospinning, applied in microorganism-based methods, biochemical equipment and methods, immobilized on or in inorganic carriers, etc., can solve complex synthesis processes, difficult product purification, and high production costs. problem, to achieve the effect of high reaction efficiency, low diffusion resistance and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of Cordyceps militaris protoplasts, the steps are as follows:

[0038] (1) Take 3 g of Cordyceps militaris cells, wash them thoroughly with sterile water, and centrifuge to get the precipitate.

[0039](2) Preparation of enzymolysis solution: take 0.1g of lysozyme, 0.1g of helicase, 0.1g of cellulase, and 0.1g of collapsing enzyme, and add them to the solution containing 0.3mol / L KCl and 0.4mol / L MgSO 4 10mL aqueous solution, fully dissolved, and then sterilized by filtration to obtain an enzymolysis solution.

[0040] (3) The precipitate was added to the enzymatic hydrolysis solution, vortexed to mix, enzymatic hydrolyzed in a water bath at 30°C for 8 hours, centrifuged, and the precipitate was the Cordyceps militaris biomass.

Embodiment 2

[0042] The preparation of Cordyceps militaris protoplasts, the steps are as follows:

[0043] (1) Take 4 g of Cordyceps militaris cells, wash them thoroughly with sterile water, and centrifuge to get the precipitate.

[0044] (2) Preparation of enzymolysis solution: take 0.1g of lytic enzyme, 0.1g of helicase, 0.1g of cellulase, and 0.1g of collapsing enzyme, and add them to the solution containing 0.5mol / L KCl and 0.2mol / L MgSO 4 5mL aqueous solution, fully dissolved, and then sterilized by filtration to obtain an enzymatic hydrolysis solution.

[0045] (3) The precipitate was added to the enzymatic hydrolysis solution, vortexed to mix, enzymolyzed in a water bath at 25°C for 3 hours, centrifuged, and the precipitate was the Cordyceps militaris biomass.

Embodiment 3

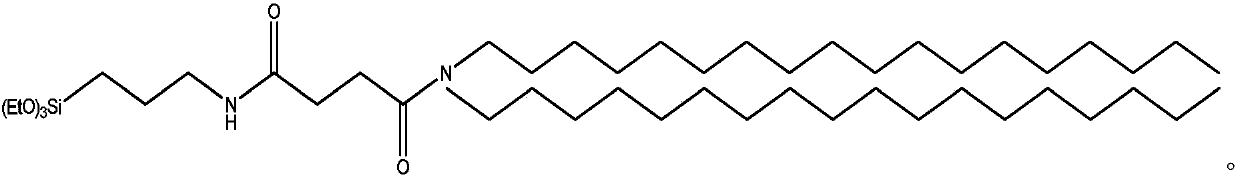

[0047] (1) Weigh 150mg of organic-inorganic composite lipid and dissolve it in 10mL of chloroform, remove the chloroform by rotary evaporation, and form a transparent lipid-like film at the bottom of the round-bottomed flask; Suspend 180g / L mannitol aqueous solution, add to the obtained lipid film, stir well and rapidly heat to 48°C, heat shock for 20s and ultrasonic in water bath; rapidly cool to 4°C, stand for 12h, and extruded through a body extruder (polycarbonate filter membrane with a pore size of 1.0 μm) to obtain a siliceous body suspension of Cordyceps militaris biomass with uniform particle size.

[0048] (2) Take chitosan (viscosity-average molecular weight 5.0×10 5 , deacetylation degree 85%), polyvinyl alcohol (weight average molecular weight is 200000) and polyethylene oxide (weight average molecular weight is 1×10 7 ) is completely dissolved in the acetic acid aqueous solution of 2% with the total mass concentration of 1.8%, adding the glycerol with the mass vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com