Catalyst for decomposing formaldehyde and preparation method of catalyst

A catalyst and formaldehyde technology, which is applied in the field of formaldehyde decomposition catalyst and its preparation, can solve the problems of easy deactivation of catalyst, low utilization efficiency of visible light, and easy water intoxication, so as to increase the amount of formaldehyde adsorption and decomposition, and reduce the possibility of water intoxication Sexuality, the effect of reducing the concentration of formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

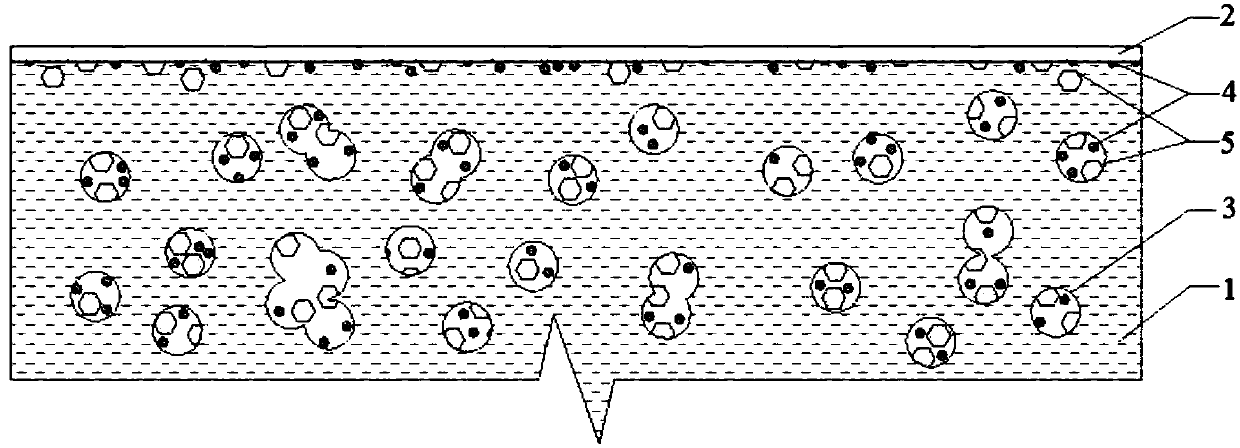

Image

Examples

preparation example Construction

[0058] 1) Preparation of activated carbon matrix: After pulverizing, drying, carbonizing, activating, cleaning and drying carbon-rich organic materials, activated carbon with high specific surface area and high adsorption is obtained;

[0059] 2) Preparation of carbon-supported catalyst: vacuumize the activated carbon substrate obtained in step 1), then impregnate it in a dimethylformamide solution containing a platinum precursor and a palladium precursor, add a binder, and extrude , and then pass through the hydrogen reduction treatment after drying to obtain a carbon-supported catalyst;

[0060] 3) Hydrophobic treatment of the carbon-supported catalyst: mixing the carbon-supported catalyst obtained in step 2) and the hydrophobic porous material in ethanol evenly, and drying to obtain the catalyst for decomposing formaldehyde.

Embodiment 1

[0062] Step 1), take a sufficient amount of coconut shells, clean them, pulverize them with a ball mill, and dry them to obtain dry materials;

[0063] Step 2), carbonization: put the dry material in a muffle furnace, and bake it under a nitrogen atmosphere at 400°C for 4 hours;

[0064] Step 3), activation: add activator KOH, the mass ratio of KOH to C is 1:5, and activate at 700°C for 3 hours;

[0065] Step 4), the generated activated carbon is acid-washed and washed to remove impurities, and then dried at 80°C;

[0066] Step 5), weigh the coconut shell activated carbon generated in the last step of 100g. At a relative pressure difference of -0.8MPa and an operating temperature of 80°C, the activated carbon was impregnated in the dimethylformamide solution of chloroplatinic acid and chloropalladium acid, and phenolic resin was added as a binder. Wherein, the weight percent concentration of noble metal in the solution is 0.3%, the weight percent concentration ratio of plati...

Embodiment 2

[0072] Step 1), the preparation process is the same as in Example 1, and the carbon-supported catalyst is made into a honeycomb module with a size of 105×35×10 mm.

[0073] Step 2), 1m 3 In a glass sealed space, add 1-2 drops of formaldehyde solution to the glass test tube, and heat it until it is completely volatilized. The formaldehyde content in the closed space is 1.8-2.8ppm, and the ambient temperature is 26-28°C.

[0074] Step 3), take two honeycomb modules and place them in a glass sealed space with a ventilation volume of 5-10m 3 / min.

[0075] After 20 to 30 minutes, 99% of the formaldehyde concentration in the space is removed, and the concentration is reduced to below 0.1ppm. Repeat steps 2 and 3 for continuous testing, and it can be reduced to 0.1ppm within a week. After 2-3 months of operation, it can still be reduced to about 0.2ppm, that is, the conversion rate of 90% is maintained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com