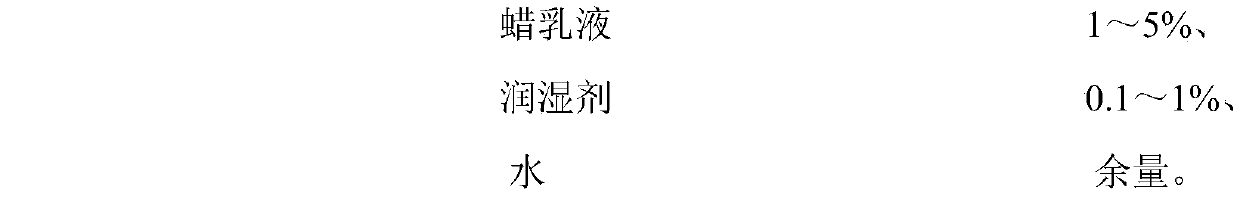

A kind of multifunctional trivalent chromium passivator capable of continuously and rapidly treating the surface of strip steel and its preparation method and application

A multi-functional, trivalent chromium technology, applied in the coating process of metal materials, etc., can solve the problems of single function, unsatisfactory, carcinogenic and teratogenic, etc., and achieve the effect of solving blackening, convenient on-site operation, and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

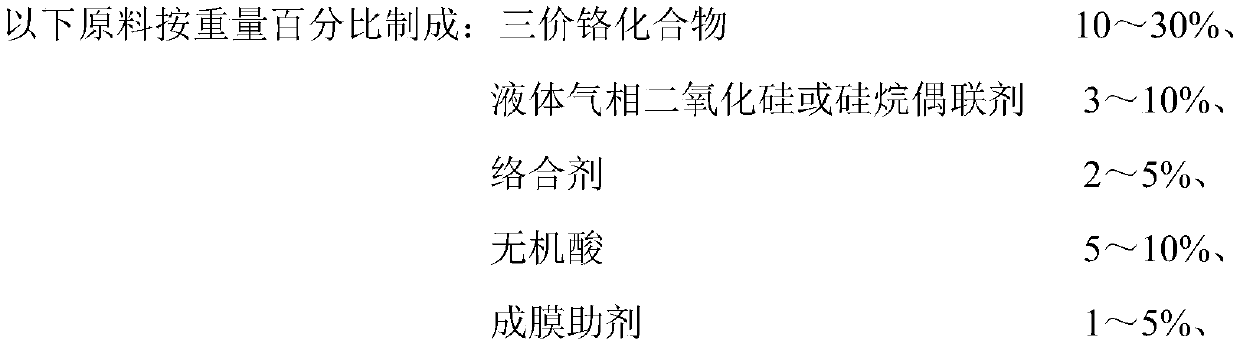

[0024] (1) The composition of the multifunctional trivalent chromium passivator that can continuously and rapidly process the surface of the strip steel

[0025]

[0026] (2) Preparation method

[0027] In pure water, under medium-speed stirring at 500r / min, add lactic acid and stir for 10 minutes; add phosphoric acid and stir for 10 minutes; add hydrofluoric acid and stir for 10 minutes; add nitric acid and stir for 10 minutes; Complete hydrolysis; add liquid fumed silica and stir for 10 minutes; add ammonium fluoride and stir for 10 minutes; add cobalt nitrate and stir for 10 minutes; add non-ionic oxidized polyethylene wax and stir for 5 minutes; add chromium nitrate and stir for 10 minutes; add fatty alcohol polyoxyethylene ether and stir for 7 minutes , and stir evenly to obtain the target product.

Embodiment 2

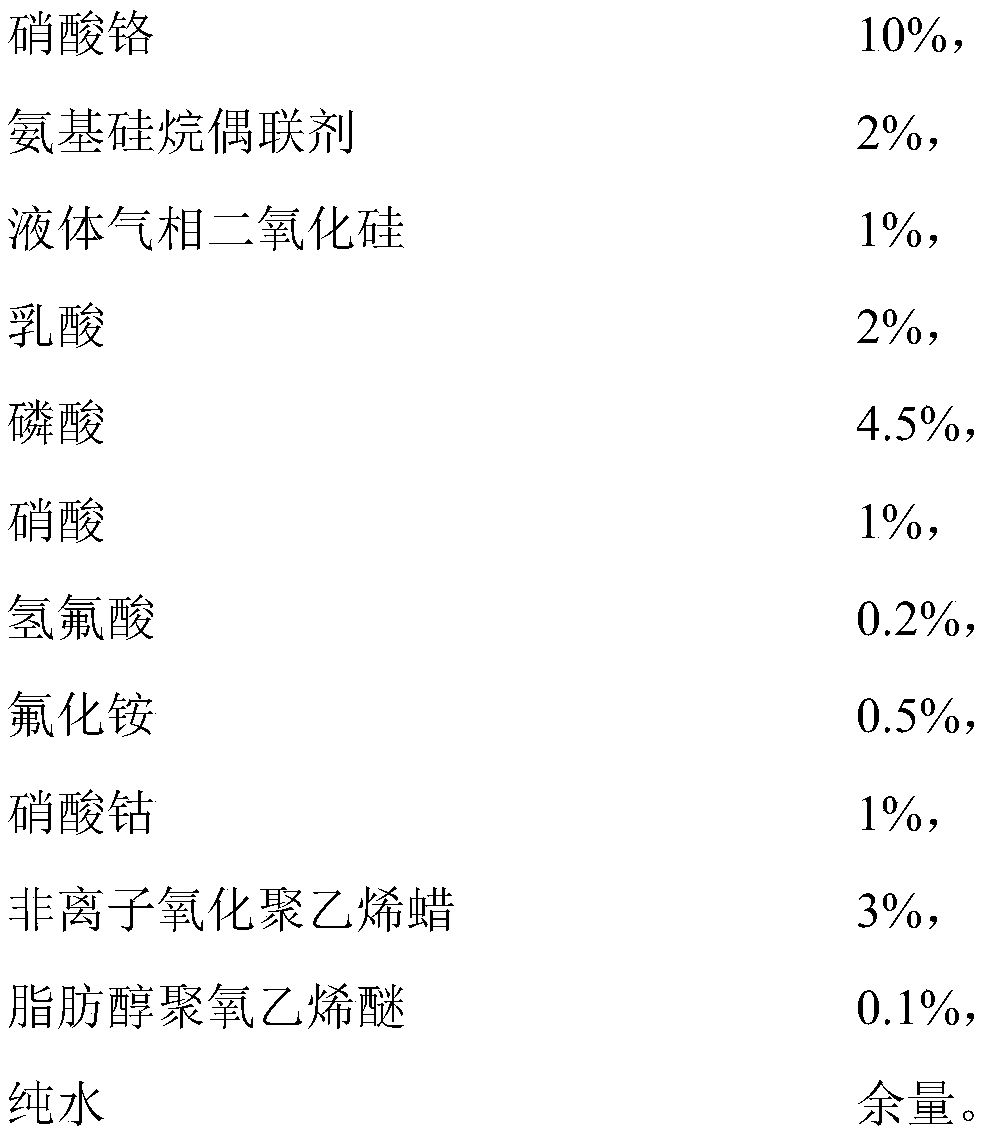

[0029] (1) The composition of the multifunctional trivalent chromium passivator that can continuously and rapidly process the surface of the strip steel

[0030]

[0031]

[0032] (2) Preparation method

[0033] In pure water, under medium-speed stirring at 500r / min, add acetic acid and stir for 10 minutes; add citric acid and stir for 10 minutes; add phosphoric acid and stir for 10 minutes; add nitric acid and stir for 10 minutes; add epoxy silane coupling agent and stir for 30 minutes to couple the silane Add liquid fumed silica and stir for 10 minutes; add potassium nitrate and stir for 10 minutes; add sodium dihydrogen phosphate and stir for 10 minutes; add ammonium fluoride and stir for 10 minutes; add cobalt nitrate and stir for 10 minutes; add non-ionic oxidized polyethylene wax and stir for 5 minutes; Add chromium sulfate and stir for 10 minutes; add chromium phosphate and stir for 10 minutes; add fatty alcohol polyoxyethylene ether and stir for 7 minutes, and st...

Embodiment 3

[0035] (1) The composition of the multifunctional trivalent chromium passivator that can continuously and rapidly process the surface of the strip steel

[0036]

[0037]

[0038] (2) Preparation method

[0039] In pure water, under medium-speed stirring at 500r / min, add acetic acid and stir for 10 minutes; add oxalic acid and stir for 10 minutes; add nitric acid and stir for 10 minutes; add hydrofluoric acid and stir for 10 minutes; Stir the silane coupling agent for 30 minutes to completely hydrolyze the silane; add sodium nitrate and stir for 10 minutes; add cobalt nitrate and stir for 10 minutes; add non-ionic oxidized polyethylene wax and stir for 5 minutes; add chromium dihydrogen phosphate and stir for 10 minutes; add fatty alcohol polyoxyethylene ether and stir for 7 minutes , and stir evenly to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com