A kind of preparation method of paper-based flexible planar supercapacitor

A supercapacitor and paper-based flexible technology, applied in the energy field, can solve the problems of reducing the resolution of the interdigital electrode structure, affecting the performance of supercapacitors, and increasing the production cost, and achieve the effect of light weight, high flexibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

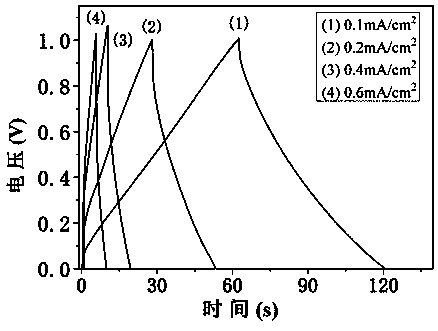

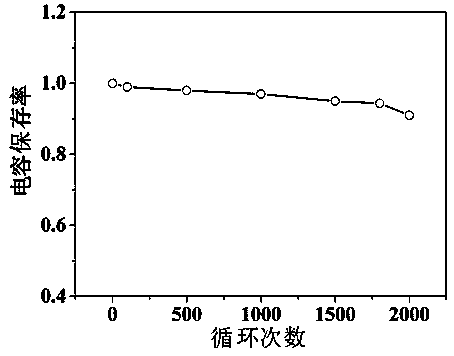

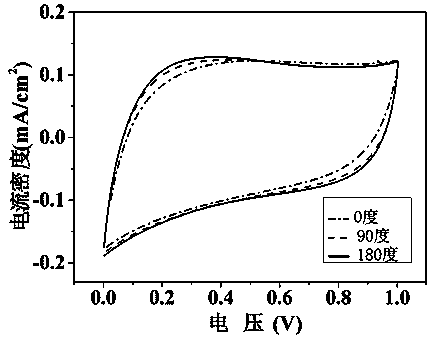

[0028] Graphene-based symmetrical paper-based flexible planar supercapacitors are prepared, in which the electrode material is graphene, the electrolyte is polyvinyl alcohol-sulfuric acid-water, and the paper substrate is qualitative filter paper for laboratory use.

[0029] 1. Preparation of symmetric graphene interdigitated electrodes

[0030] Preparation of the interdigitated electrode model: stick the qualitative filter paper used in the laboratory on the printing paper with scotch tape, print the designed interdigitated electrode array structure on the filter paper with a laser printer, and then cut it manually along the printing trace to obtain a foldable Interdigitated electrode model. In the interdigitated electrode array structure designed in this embodiment, each set of comb electrodes includes 2 finger electrodes, the size of the finger electrodes is 14×0.9mm (length×width), and the electrode interval is 1.0mm.

[0031] Preparation of graphene electrode slurry: dis...

Embodiment 2

[0040] Utilize the method of the present invention to prepare an asymmetric paper-based flexible planar supercapacitor, the negative electrode is graphene, the positive electrode is a manganese oxide-graphene composite material, the electrolyte is carboxymethyl cellulose-sodium sulfate hydrogel electrolyte, and the flexible paper base adopts office Use printer paper.

[0041] Use a laser printer to directly print the designed interdigitated electrode array structure on printing paper. In this embodiment, the preparation method and steps of the interdigitated electrode model and the preparation steps of the graphene electrode slurry are the same as in Example 1; in this embodiment In the designed interdigital electrode array structure, each set of comb electrodes includes 5 finger electrodes, the size of the finger electrodes is 10×0.8mm (length×width), and the electrode interval is 0.5mm.

[0042] In the manganese oxide-graphene composite cathode material in this embodiment, t...

Embodiment 3

[0046] Utilize the method of the present invention to prepare an asymmetric paper-based flexible planar supercapacitor, wherein the negative pole is a carbon nanotube, the positive pole is a polypyrrole-carbon nanotube composite material, the electrolyte is a carboxymethylcellulose-sodium sulfate hydrogel electrolyte, and the flexible substrate For dust-free paper.

[0047] Stick the dust-free paper on the printing paper with transparent tape, and use a laser printer to print the designed interdigitated electrode array structure on the dust-free paper. The preparation method and steps of the interdigitated electrode model in this embodiment are the same as those in Embodiment 1; In the interdigitated electrode array structure designed in this embodiment, each set of comb electrodes includes 3 finger electrodes, the size of the finger electrodes is 8×0.6mm (length×width), and the electrode interval is 0.5mm.

[0048] Carbon nanotube electrode slurry preparation: Weigh 0.1 mg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com