Feruloyl esterase gene, genetically engineered strain, and preparation method and application of feruloyl esterase

A genetically engineered strain and ferulic acid esterase technology, applied in the field of bioengineering, can solve the problems of low yield of ferulic acid esterase, unusable target products, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

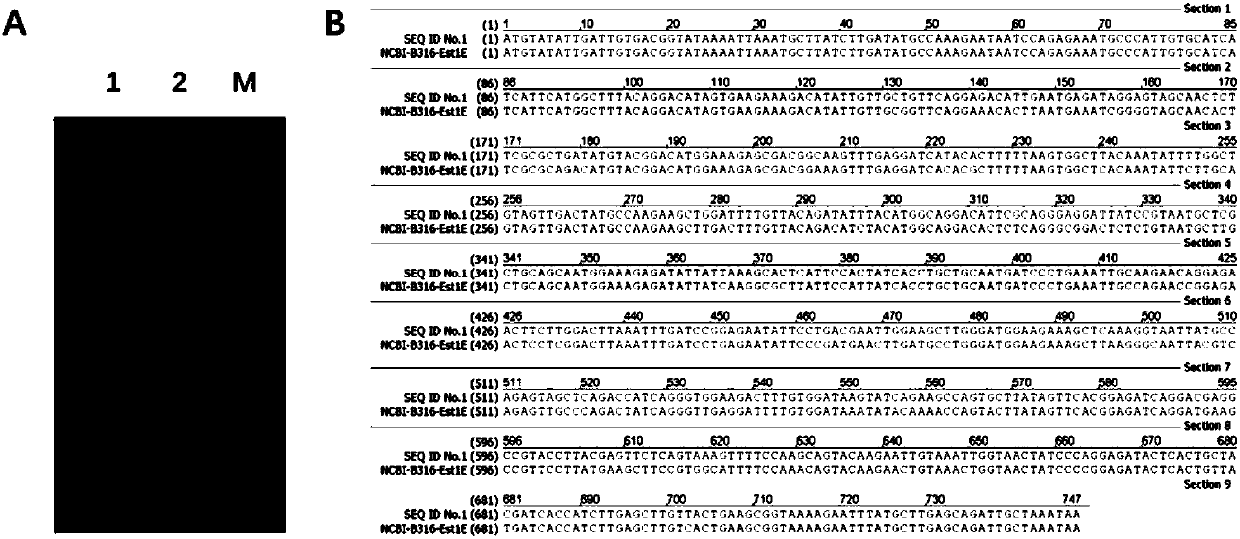

[0035] Example 1 Extraction of yak rumen microbial genome and cloning of ferulic acid esterase gene Est1E

[0036] The rumen contents of two Chinese Qinghai yaks were collected from a slaughterhouse in Xining City, Qinghai Province, China, filtered through three layers of gauze, and the filtrate was centrifuged to collect rumen microbial cells, which were frozen at -80°C until use. Take 100-200μL bacterial sample, wash 2-3 times with 1mL PBS, add 650μL DNA extraction buffer (100mM Tris-HCl pH8.0, 100mM Na 2 EDTA pH8.0, 100mM Na 3 PO 4 Buffer pH8.0; 1.5M NaCl, 1% CTAB, pH8.0), mix well, place at -80°C, then place in 65°C water bath to thaw, repeat freeze-thaw three times; add 3-4μL lysate after cooling Shake the enzyme (100mg / L) horizontally (37°C, 225rpm) in a shaker for about 30min; add 2-3μL of proteinase K (20mg / mL) and continue shaking for about 30min; add 50-70uL of 20% SDS, mix well, 65 Incubate at ℃ for 1-2 hours, mix by inverting the centrifuge tube every 10-20 minu...

Embodiment 2

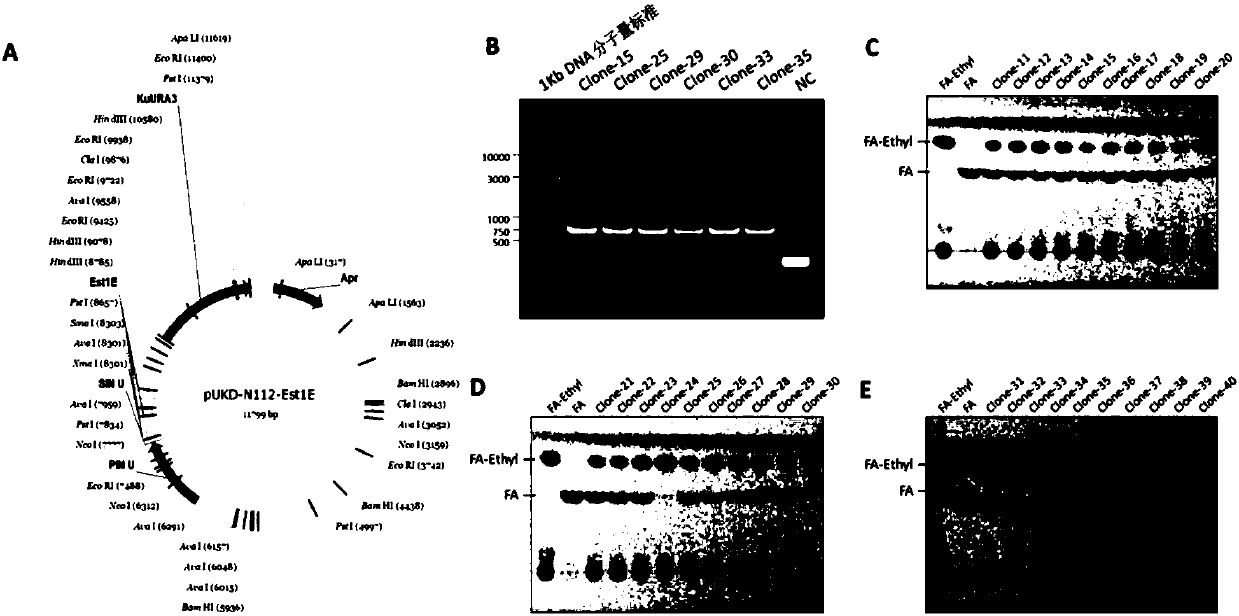

[0038] Embodiment 2 Construction of ferulic acid esterase gene Est1E recombinant Kluyveromyces expression strain

[0039] According to the yak rumen microbial ferulic acid esterase Est1E sequence obtained by sequencing, the gene was inserted into the two restriction Sma I and Not I of Kluyveromyces marxianus expression vector pUKD-N112 by conventional molecular cloning methods. In the middle of the restriction site, the recombinant plasmid pUKD-N112-Est1E was obtained. The recombinant plasmid can utilize the promoter and signal peptide of Kluyveromyces marx inulinase to carry out the recombinant expression and secretion of Est1E.

[0040] Using the uracil auxotrophic Kluyveromyces marx strain Fim-1ura3Δ as the expression host, inoculate Fim-1ura3Δ in a glass test tube containing 3 mL of YEPD medium, and culture OD overnight on a shaker at 30°C 600 to 12-15. Take 1 mL of bacterial liquid, collect the bacterial cells by centrifugation at 8 000 rpm for 30 s, add 1 mL of sterile...

Embodiment 3

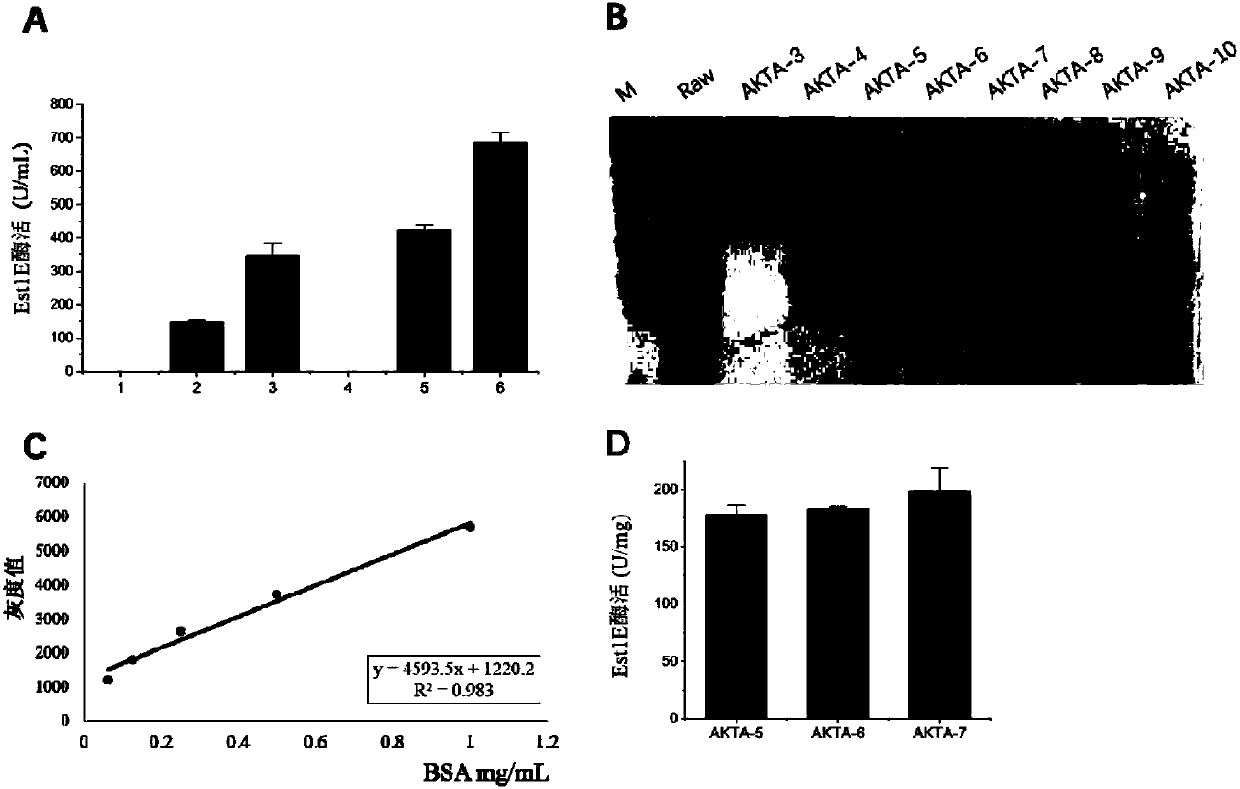

[0043] Example 3 Ferulic esterase ferulic acid esterase recombinantly expressed by Kluyveromyces marxe and its preparation

[0044] The clones with higher degradation efficiency screened out from the hydrolysis experiment of ethyl ferulic acid were used as fermentation bacteria and carried out small-scale fermentation in a 5L fermenter. According to the fermentation of 2g of glucose to produce 1g of yeast cells, and the yeast cell C / N=5:1, the Kluyveromyces marx recombinant bacteria fermentation medium was designed. The source of N in the medium was yeast powder, and the source of C was glucose, and fed-batch culture High-density fermentation of ferulic acid esterase K. The initial volume of the fermentation medium is 1.6L, containing 2% yeast powder and 5% glucose. When the sugar concentration is less than 1%, feed feeding is started, the concentration of N source and carbon source is 5:1, and the concentration of glucose is controlled at about 1%, and the fermentation cycle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com