High dielectric adhesive tape and preparation method thereof

A high-dielectric, tape technology, used in adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of reasonable and safe use of power grid systems, poor adhesion of insulating silicone rubber, and high pressure resistance. Not good and other problems, to achieve the effect of high production efficiency, good adhesion, high strength physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

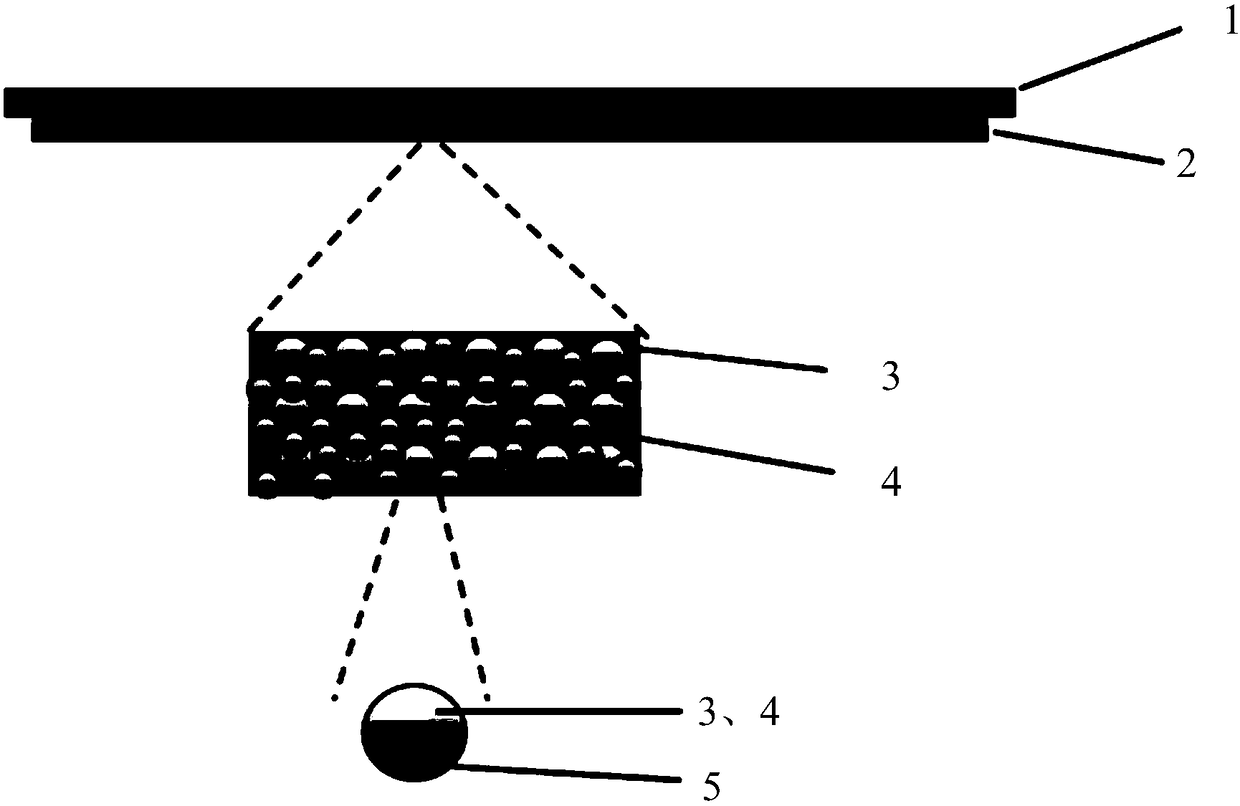

[0028] like figure 1 As shown, a high-dielectric tape applied to high-voltage cables includes a tape substrate 1 and an adhesive layer (dielectric layer) 2, wherein the substrate 1 is made of kraft paper, and the adhesive layer 2 includes the following components in parts by mass: 160 parts of nitrile rubber 1051M50, 590 parts of barium titanate particles, 18 parts of bis-octyl diphenylamine, 15 parts of hydrogenated rosin resin and 20 parts of vinyltrimethoxysilane, wherein the barium titanate particles include at least two particle sizes : Particles 3 and 4, the surfaces of the barium titanate particles 3 and 4 are coated with silicon dioxide 5 .

[0029] The preparation method of the above-mentioned high dielectric tape comprises the following steps.

[0030] S1. Firstly, the barium titanate particles are coated on the surface by the sol-gel method.

[0031] Adjust the pH of the 0.2 mol / L water glass solution to 10 with 1 mol / L HCl to form a silicon solution. Then add ba...

Embodiment 2

[0037] A high-dielectric tape for high-voltage cables, including a tape substrate and an adhesive layer, wherein the substrate is made of PVC, and the adhesive layer includes the following components in parts by mass: 150 parts of butyl rubber IIR1751, strontium barium titanate particles 90 parts, 15 parts of bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide, 5 parts of C9 petroleum resin and coupling agent γ-(methacryloyloxy)propyltrimethoxysilane 15 parts, wherein the strontium barium titanate particles include at least two particle sizes, and the surface of the strontium barium titanate particles is coated with silicon dioxide.

[0038] The preparation method of the above-mentioned high dielectric tape comprises the following steps.

[0039] S1. First, the surface coating treatment of barium strontium titanate particles is carried out by using the sol-gel method.

[0040] Adjust the pH of the 0.2 mol / L water glass solution to 10 with 1 mol / L HCl to form a silicon solution. ...

Embodiment 3

[0046] A high-dielectric tape for high-voltage cables, including a tape substrate and an adhesive layer, wherein the substrate is PE, and the adhesive layer includes the following components in parts by mass: 150 parts of butadiene rubber BR9000, 85 parts of barium titanate particles 18 parts, 18 parts of dialkyl diphenylamine, 15 parts of maleic rosin resin and 15 parts of cyclohexylmethyldimethoxysilane, wherein the barium titanate particles include at least two particle sizes, and the surface coating of the barium titanate particles silica.

[0047] S1. Firstly, the barium titanate particles are coated on the surface by the sol-gel method.

[0048] Adjust the pH of the 0.2 mol / L water glass solution to 10 with 1 mol / L HCl to form a silicon solution. Then add barium titanate particles whose particle size is divided into 100nm and 500nm, so that the mass fraction of barium titanate is 25% (ratio in the whole solution), and the volume ratio of the two kinds of particles is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com