Preparation method for graft-modified hydrophobic associated polymer

A technology of hydrophobic association and graft modification, which is applied in the field of preparation of graft-modified hydrophobic association polymers, which can solve problems such as loss of use value, stability problems, and easy degradation, and achieve safe use and convenient storage , the effect of high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

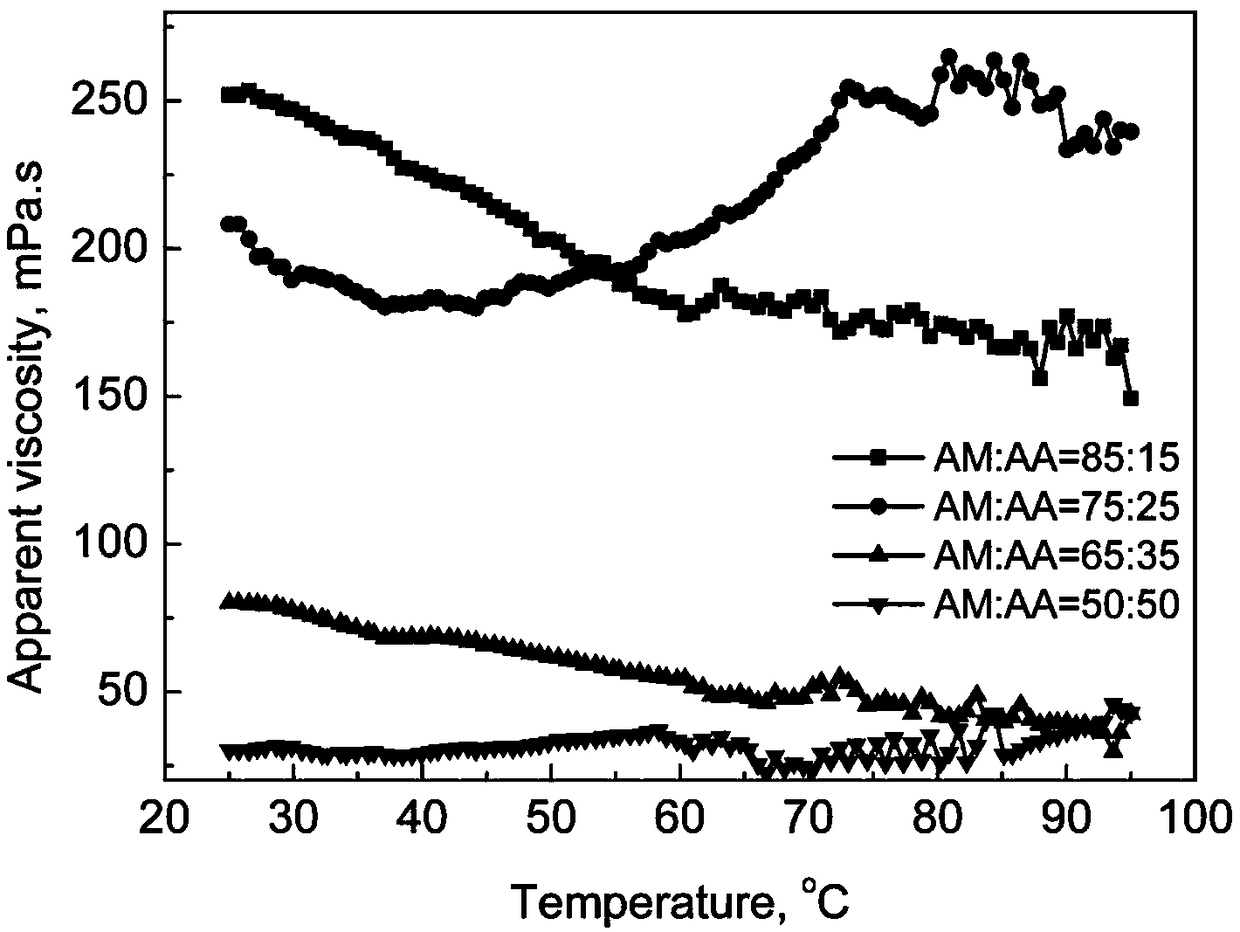

Image

Examples

Embodiment 1

[0039] Weigh 1.25g of hydroxypropyl methylcellulose (HPMC) and add it into a four-necked bottle equipped with agitator, condenser, nitrogen pipe and thermometer, and measure 60mL distilled water into the four-necked bottle, seal it, and stir it mechanically Let it dissolve completely. Weigh 13.69g of acrylamide (AM) and 4.56g of acrylic acid (AA) into a beaker, measure 10mL of distilled water to dissolve, adjust the pH to 7.0 with NaOH solution, add to the above mixture, stir to dissolve. Weigh 0.5 g of stearyl methacrylate (SMA) and 5.76 g of sodium dodecyl sulfate (SDS) into a beaker, measure 20 mL of distilled water and stir to dissolve into an emulsion. Weigh 0.318g potassium persulfate (K 2 S 2 o 8 ) and 0.08g sodium bisulfite (NaHSO3 ) into the above mixture, stirred to dissolve, put the four-neck flask in a 25°C constant temperature water bath, stirred nitrogen and deoxygenated for 30 minutes, raised the temperature of the water bath to 60°C and reacted for 8 hours t...

Embodiment 2

[0041] Weigh 1.25g of hydroxypropyl methylcellulose (HPMC) and add it into a four-necked bottle equipped with agitator, condenser, nitrogen pipe and thermometer, and measure 60mL distilled water into the four-necked bottle, seal it, and stir it mechanically Let it dissolve completely. Weigh 13.31g of acrylamide (AM) and 4.44g of acrylic acid (AA) into a beaker, measure 10mL of distilled water to dissolve, adjust the pH to 7.0 with NaOH solution, add to the above mixture, stir to dissolve. Weigh 1.0 g of stearyl methacrylate (SMA) and 5.76 g of sodium dodecyl sulfate (SDS) into a beaker, measure 20 mL of distilled water and stir to dissolve into an emulsion. Weigh 0.318g potassium persulfate (K 2 S 2 o 8 ) and 0.08g sodium bisulfite (NaHSO 3 ) into the above mixture, stirred to dissolve, put the four-neck flask in a 25°C constant temperature water bath, stirred nitrogen and deoxygenated for 30 minutes, raised the temperature of the water bath to 60°C and reacted for 8 hours...

Embodiment 3

[0043] Weigh 1.25g of hydroxypropyl methylcellulose (HPMC) and add it into a four-necked bottle equipped with agitator, condenser, nitrogen pipe and thermometer, and measure 60mL distilled water into the four-necked bottle, seal it, and stir it mechanically Let it dissolve completely. Weigh 12.56g of acrylamide (AM) and 4.19g of acrylic acid (AA) into a beaker, measure 10mL of distilled water to dissolve, adjust the pH to 7.0 with NaOH solution, add to the above mixture, stir to dissolve. Weigh 2.0 g of stearyl methacrylate (SMA) and 5.76 g of sodium dodecyl sulfate (SDS) into a beaker, measure 20 mL of distilled water and stir to dissolve into an emulsion. Weigh 0.318g potassium persulfate (K 2 S 2 o 8 ) and 0.08g sodium bisulfite (NaHSO 3 ) into the above mixture, stirred to dissolve, put the four-neck flask in a 25°C constant temperature water bath, stirred nitrogen and deoxygenated for 30 minutes, raised the temperature of the water bath to 60°C and reacted for 8 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com