A method for purifying stone coal acid leaching solution and recovering aluminum, potassium and iron

A technology of stone coal acid and aluminum recovery, which is applied in the field of purification of stone coal acid leaching solution and recovery of aluminum, potassium and iron, which can solve the problems of cumbersome separation process and achieve the effect of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The composition of stone coal acid leaching liquid used in this example is V 1.72g / L, Al 9.32g / L, K 1.73g / L, Fe0.59g / L.

[0077] Follow the steps below to purify stone coal acid leaching solution and recover aluminum, potassium and iron:

[0078] (1) 2L stone coal pickling solution was cooled from 50°C to 40°C for cooling and crystallization, and solid-liquid separation was carried out to obtain 45.7g of alum and 1.96L of filtrate;

[0079] (2) Adjust the pH of the filtrate obtained in step (1) from -1.2 to -1 with sodium carbonate and potassium hydroxide, and then add peroxide, persulfate, sulfite and pyrosulfite to adjust the redox potential Be 850mV, obtain the solution after treatment;

[0080] (3) Heat the solution obtained in step (2) to 200°C, add sodium hydroxide, ammonia water and sodium bicarbonate to control and keep the pH of the solution at -1, add ferric compounds, nitrite, chlorate, and thiosulfate Control and maintain the redox potential of the solutio...

Embodiment 2

[0084] The composition of stone coal acid leaching liquid used in this example is V 1.72g / L, Al 9.32g / L, K 1.73g / L, Fe0.59g / L.

[0085] Follow the steps below to purify stone coal acid leaching solution and recover aluminum, potassium and iron:

[0086] (1) Primary crystallization: add 2.9g sodium sulfate, 16.8g ammonium bisulfate, 3.6g ammonium bicarbonate and 16g potassium bicarbonate in 3L stone coal pickling solution (the addition of additive is to make the aluminum in the stone coal pickling solution Form alum and iron to form 0.5 times of the theoretical amount of jarosite), drop from 70 ℃ to room temperature (20 ℃) cooling crystallization, solid-liquid separation, obtain 264.1g alum and 2.85L filtrate;

[0087] (2) Solution treatment: the filtrate obtained in step (1) is at first adjusted to pH from -0.5 to 0 with ammoniacal liquor, ammonium carbonate, ammonium bicarbonate, sodium bicarbonate, potassium carbonate and calcium hydroxide, then passes into air, sulfur dio...

Embodiment 3

[0092] The composition of stone coal acid leaching liquid used in this example is V 1.72g / L, Al 9.32g / L, K 1.73g / L, Fe0.59g / L.

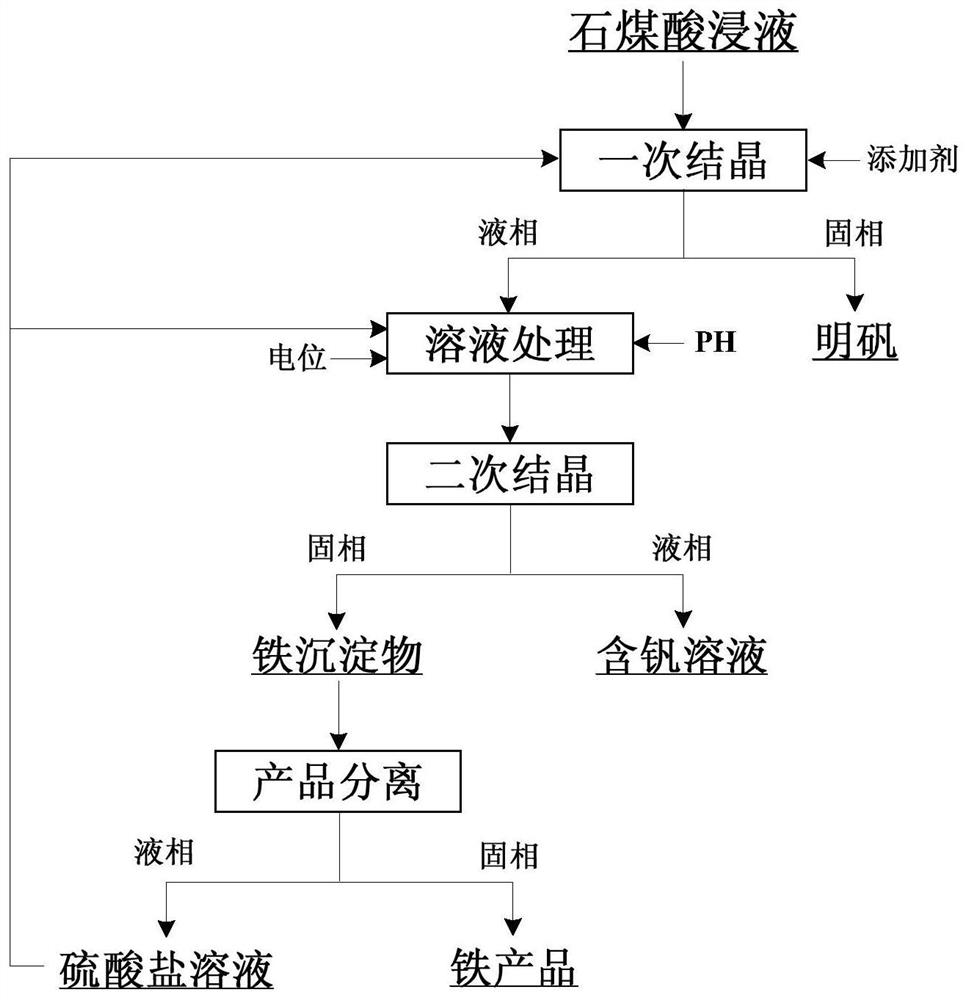

[0093] Such as figure 1 As shown, the following steps are followed to purify the stone coal acid leaching solution and recover aluminum, potassium and iron:

[0094] (1) Primary crystallization: add 8.7kg ammonium sulfate, 0.5kg ammonium carbonate and 0.69kg ammonium bicarbonate in 50L stone coal pickling solution (the addition of additive is to make the aluminum in stone coal pickling solution form alum and iron form yellow 5 times the theoretical amount of alum), dropped from 90°C to 0°C for cooling crystallization, solid-liquid separation, obtained 7.5kg alum and 46L filtrate;

[0095] (2) Solution treatment: the filtrate obtained in step (1) is first adjusted to pH from 1 to 2 with sodium hydroxide, potassium bicarbonate, calcium oxide and calcium carbonate, then feeds oxygen, ozone, adds perchlorate, nitrite Nitrate, nitrate, manganese-contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com