Superhydrophobic self-cleaning photovoltaic glass coating solution and coating process thereof

A photovoltaic glass and coating solution technology, applied in antifouling/underwater coatings, coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor compactness, reduced transmittance, and unstable sol-gel film structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

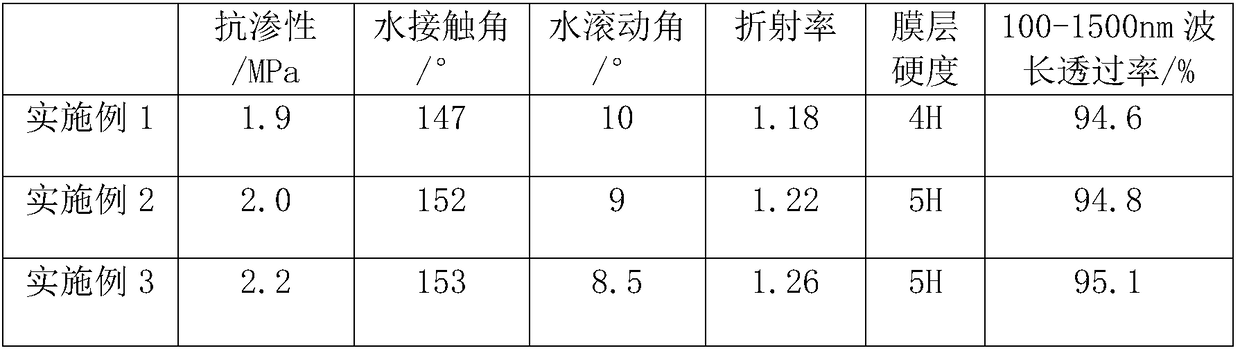

Examples

Embodiment 1

[0019] A super-hydrophobic self-cleaning photovoltaic glass coating solution, comprising the following components by weight: 20 parts by weight of water-based fluorocarbon emulsion, 25 parts of epoxy silicone oil, 15 parts of polysiloxane modified polyurethane, 6 parts of polytetrafluoroethylene, 15nm fuller 5 parts of olefin, 4 parts of 20nm titanium dioxide, 10 parts of 40nm optical anti-reflection agent, 2 parts of degreasing agent, 0.2 part of γ-ureidopropyl-trimethoxysilane;

[0020] Wherein, the optical antireflection agent includes the following components in weight ratio: 5% yttrium lithium fluoride, 2% magnesium fluoride, 0.7% lithium tantalate, 0.3% bismuth oxide, 2% zirconia, and 90% silica aerosol; The degreasing agent includes the following components in weight ratio: sodium tripolyphosphate 16%, magnesium lithium silicate 10%, sodium lauryl sulfonate 21%, polyoxyethylene-polyoxypropylene copolymer 43%, immobilized lipase 6%, immobilized protease 4%.

[0021] The coat...

Embodiment 2

[0023] A super-hydrophobic self-cleaning photovoltaic glass coating solution, comprising the following parts by weight: 25 parts of water-based fluorocarbon emulsion, 30 parts of epoxy silicone oil, 20 parts of polysiloxane modified polyurethane, 9 parts of polytetrafluoroethylene, 18nm rich 6 parts of Leene, 5 parts of 23nm titanium dioxide, 13 parts of 50nm optical antireflection agent, 5 parts of degreasing agent, 0.6 parts of N-phenyl-γ-aminopropyl-dimethoxysilane;

[0024] Among them, the optical antireflection agent includes the following components in weight ratio: 7% lithium yttrium fluoride, 3.5% magnesium fluoride, 1.1% lithium tantalate, 0.4% bismuth oxide, 5% zirconium oxide, and 85% silica aerosol; The degreasing agent includes the following components in weight ratio: sodium tripolyphosphate 20%, magnesium lithium silicate 11%, sodium dodecyl sulfonate 23%, polyoxyethylene-polyoxypropylene copolymer 34%, immobilized lipase 7%, immobilized protease 5%.

[0025] The co...

Embodiment 3

[0027] A super-hydrophobic self-cleaning photovoltaic glass coating solution, including the following components by weight: 30 parts of water-based fluorocarbon emulsion, 35 parts of epoxy silicone oil, 25 parts of polysiloxane modified polyurethane, 12 parts of polytetrafluoroethylene, 20nm rich 7 parts of Leene, 6 parts of 25nm titanium dioxide, 15 parts of 60nm optical anti-reflection agent, 8 parts of degreaser, 1 part of vinyl triethoxysilane;

[0028] Among them, the optical antireflection agent includes the following components in weight ratio: 9% lithium yttrium fluoride, 6% magnesium fluoride, 1.5% lithium tantalate, 0.5% bismuth oxide, 8% zirconium oxide, and 75% silica aerosol; The oil agent includes the following ingredients in weight ratio: sodium tripolyphosphate 24%, magnesium lithium silicate 12%, sodium lauryl sulfonate 25%, polyoxyethylene-polyoxypropylene copolymer 25%, immobilized lipase 8 %, immobilized protease 6%.

[0029] The coating process of the above-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com