Amino acid hydrogel microsphere and preparation method and application thereof

A technology of hydrogel microspheres and amino acids, applied in chemical instruments and methods, pharmaceutical formulations, other chemical processes, etc., can solve limited problems, chronic poisoning heavy metal removal ability and other problems, achieve high selectivity, avoid adverse reactions, The effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

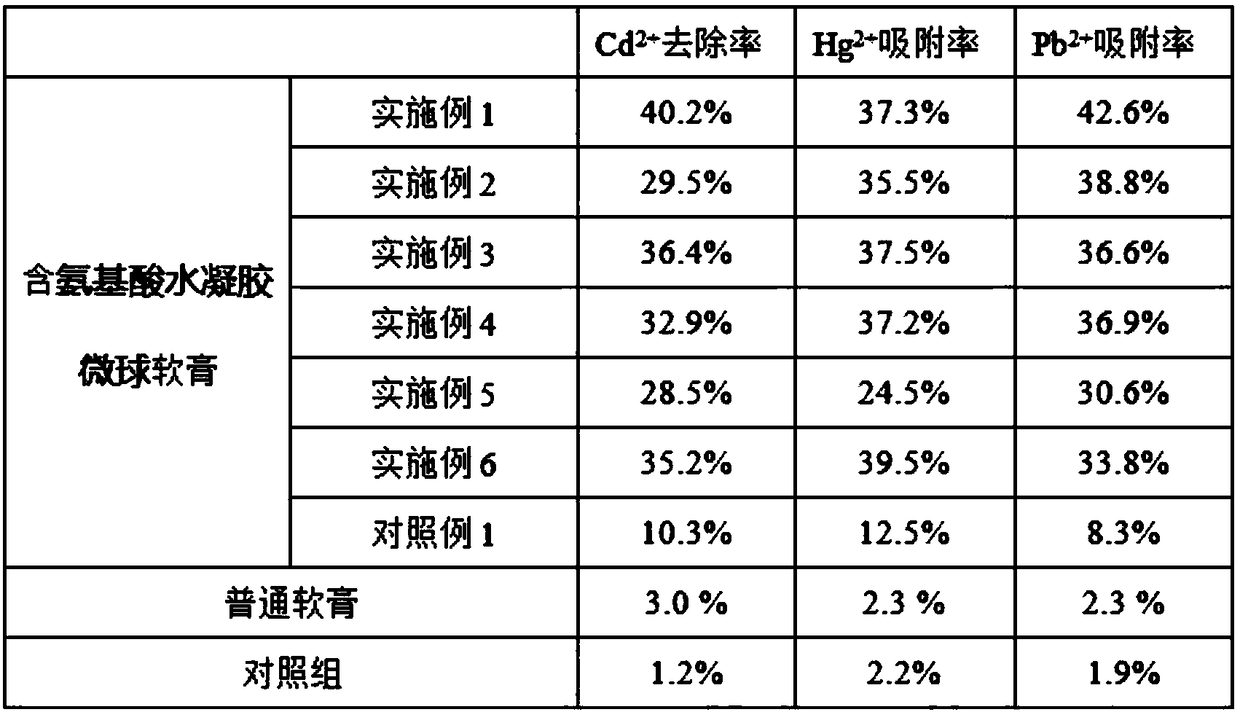

Examples

Embodiment 1

[0038] (1) Preparation of polyaspartic acid hydrogel microspheres containing disulfide bonds

[0039] Disperse 100g of polyaspartic acid in 1000g of water, then add 500g of methanol, 10g of N,N'-bis(acryloyl)cystamine, 10g of glycidyl methacrylate, 10g of cross-linking agent ethylene glycol dishrinkle Glyceryl ether, 0.3g ammonium persulfate, stir well to obtain the water phase; disperse 10g Tween-20 in 500g cyclohexane, stir at room temperature for 1h to obtain the oil phase; add 100ml water phase to 150ml oil phase , stirring to control the particle size, reacting at 90°C for 2 hours, cooling down, and purifying to obtain polyaspartic acid hydrogel microspheres containing disulfide bonds;

[0040] (2) Preparation of amino acid hydrogel microspheres

[0041] Mix 100 g of polyaspartic acid hydrogel microspheres containing disulfide bonds obtained in step (1) with 5000 g of PBS buffer solution containing 100 g of dithiothreitol, adjust the pH to 9, stir for 10 h, and purify to...

Embodiment 2

[0043] (1) Preparation of polyaspartic acid hydrogel microspheres containing disulfide bonds

[0044] Disperse 100g polyaspartic acid in 8000g water, then add 5000g ethanol, 50g N,N'-bis(acryloyl)cystamine, 0.1g glycidyl methacrylate, 50g crosslinking agent diethylene glycol (Diethylene glycol) diglycidyl ether, 0.1g potassium persulfate, stir well to obtain the water phase; disperse 10g Tween-60 in 200g n-heptane, stir at room temperature for 5h to obtain the oil phase; Add phase to 100ml oil phase, stir to control the particle size, react at 20°C for 10h, cool down, purify, and obtain polyaspartic acid hydrogel microspheres containing disulfide bonds;

[0045] (2) Preparation of amino acid hydrogel microspheres

[0046] Mix 100g of disulfide bond-containing polyaspartic acid hydrogel microspheres obtained in step (1) with 3000g of PBS buffer solution containing 50g of vitamin C, adjust the pH to 7.5, stir for 5h, and purify to obtain a particle size of 0.05mm Amino acid hy...

Embodiment 3

[0048] (1) Preparation of polyaspartic acid hydrogel microspheres containing disulfide bonds

[0049] Disperse 100g of polyaspartic acid in 2000g of water, then add 0.1g of acetonitrile, 10g of N,N'-bis(acryloyl)cystamine, 20g of glycidyl methacrylate, and 10g of crosslinking agent trimethylol Propane triglycidyl ether, 1g sodium persulfate, stir well to get water phase; disperse 10g Tween-80 in 1000g pentane, stir at room temperature for 2h to get oil phase; add 100ml water phase to 1000ml oil phase , stir to control the particle size, react at 60°C for 8 hours, cool down, and purify to obtain polyaspartic acid hydrogel microspheres containing disulfide bonds;

[0050] (2) Preparation of amino acid hydrogel microspheres

[0051] Mix 100 g of disulfide bond-containing polyaspartic acid hydrogel microspheres obtained in step (1) with 2000 g of PBS buffer solution containing 100 g of hydrogen peroxide, adjust the pH to 8, stir for 8 hours, and purify to obtain a particle size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com