Honeycomb low-temperature denitration catalyst and preparation technology thereof

A low-temperature denitration and preparation process technology, applied in catalyst protection, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of poor mechanical strength, no molding, and low activation energy, and achieve high strength and resistance. The effect of alkali metal ability, increasing catalyst strength, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

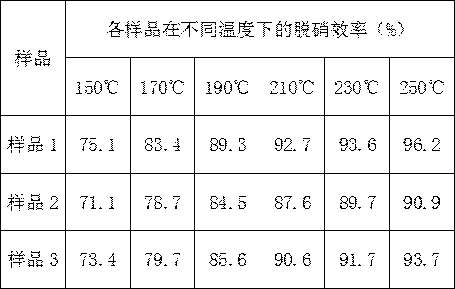

Embodiment 1

[0032] 1) Grind 100 parts by weight of the spent SCR catalyst after washing and drying to a particle size d50 of 3-5 μm, and then put it into 350 parts by weight of an aqueous solution containing 4.35 parts by weight of cobalt nitrate, 9.1 parts by weight of cerium nitrate, and 69 parts by weight of manganese nitrate , beating at 80°C for 60 minutes, adding 22.8 parts by weight of ammonium carbonate to generate a precipitate, aging for 4 hours, filtering the precipitate and washing it twice with deionized water, and drying at 90°C for 4 hours;

[0033] 2) Mix the precipitate obtained in step 1) with 0.8 parts by weight of pseudoboehmite, 3 parts by weight of silica sol, 0.8 parts by weight of hydroxymethyl cellulose, 0.5 parts by weight of graphite and 80 parts by weight of deionized water to form a plastic clay ;

[0034] 3) The plastic mud obtained in step 2) is filtered for impurities, refined and stale;

[0035] 4) Vacuum extruding the sludge obtained in step 3) to obtain...

Embodiment 2

[0038] 1) Grind 100 parts by weight of the spent SCR catalyst after washing and drying to a particle size d50 of 3-5 μm, and then put it into 500 parts by weight of an aqueous solution containing 5.43 parts by weight of cobalt oxalate, 45.2 parts by weight of cerium oxalate, and 44.12 parts by weight of manganese oxalate , beating at 100°C for 30 minutes, adding 55.52 parts by weight of ammonium carbonate to generate a precipitate, aging for 6 hours, filtering the precipitate and washing it with deionized water 4 times, and drying at 110°C for 2 hours;

[0039] 2) Mix the precipitate obtained in step 1) with 1.5 parts by weight of pseudoboehmite, 5 parts by weight of silica sol, 1.2 parts by weight of hydroxymethylcellulose, 0.8 parts by weight of graphite and 100 parts by weight of deionized water to form a plastic mud ;

[0040] 3) The plastic mud obtained in step 2) is filtered for impurities, refined and stale;

[0041] 4) Vacuum extruding the sludge obtained in step 3) t...

Embodiment 3

[0044] 1) Grind 100 parts by weight of the spent SCR catalyst after washing and drying to a particle size d50 of 3-5 μm, and then put it into 400 parts by weight of an aqueous solution containing 5.07 parts by weight of cobalt acetate, 42.2 parts by weight of cerium acetate, and 27.5 parts by weight of manganese acetate , beating at 90°C for 45 minutes, adding 56.2 parts by weight of ammonium carbonate to form a precipitate, aging for 5 hours, filtering the precipitate and washing it with deionized water for 3 times, and drying at 100°C for 3 hours;

[0045]2) Mix the precipitate obtained in step 1) with 1 part by weight of pseudoboehmite, 4 parts by weight of silica sol, 1 part by weight of hydroxymethylcellulose, 0.7 parts by weight of graphite and 90 parts by weight of deionized water to form a plastic clay ;

[0046] 3) The plastic mud obtained in step 2) is filtered for impurities, refined and stale;

[0047] 4) Vacuum extruding the sludge obtained in step 3) to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com