A method for the separation, purification and reuse of graphene from hydrogen-nitrogen mixed tail gas in MOCVD process

A technology of graphene and mixed gas, which is applied in the field of graphene separation, purification and reuse of hydrogen and nitrogen mixed tail gas in MOCVD process, can solve the problems of hydrogen and nitrogen yield and purity, high process energy consumption, etc., and achieve excellent separation characteristics, The effect of improving economic value and smoothing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

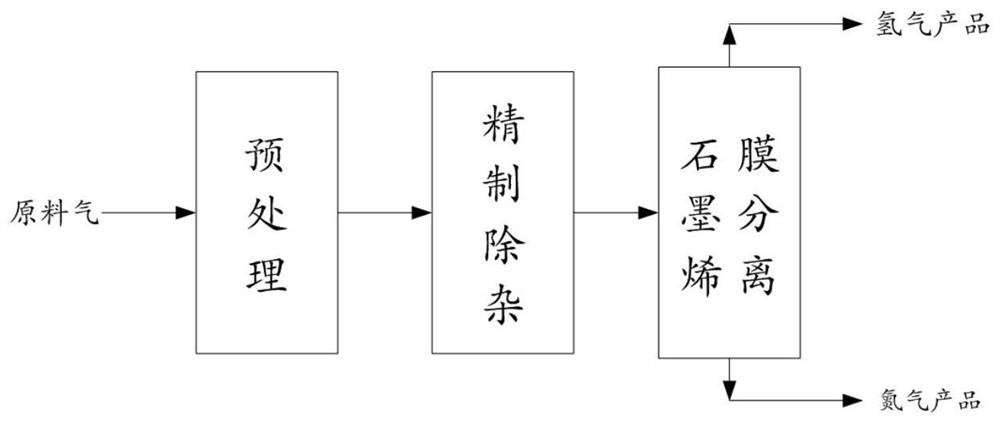

[0029] Such as figure 1 As shown, a method for the separation, purification and reuse of graphene from hydrogen and nitrogen tail gas in MOCVD process, the specific implementation steps include.

[0030] (1) Raw material gas, that is, normal or low pressure MOCVD (metal oxide chemical vapor deposition) to prepare exhaust gas in the process of light-emitting diode (LED) based on gallium nitride (GaN) epitaxial wafer growth, after deamination including dust removal, oil removal and deamination The hydrogen-nitrogen mixture obtained after pretreatment including drying and fine filtration, the flow rate is 1,000 standard cubic meters per hour, and its main composition is nitrogen (N 2 ): 56.4% (v / v, the following are similar), hydrogen (H 2 ): 43.4%, ammonia (NH 3 ): 0.2% and other trace amounts of organometallics, methane (CH 4 ), water (H 2 O), carbon monoxide (CO), carbon dioxide (CO 2 ), oxygen (O 2 ) and other impurity components, the pressure is normal pressure, and th...

Embodiment 2

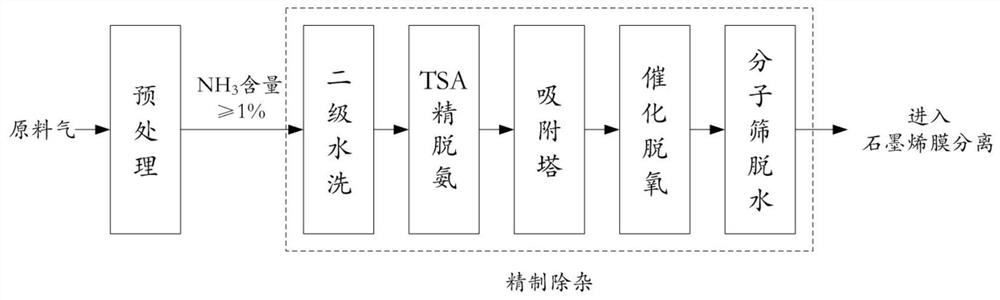

[0034] Such as figure 2 As shown, on the basis of Example 1, the ammonia impurity component content in the raw material gas obtained through pretreatment is about 1%. System, after the temperature-swing adsorption fine deamination, add a one-time chemisorption deamination adsorption tower in front of the ammonia purifier, so that the ammonia content is reduced to below 0.1ppm, so as to ensure the normal operation of the graphene membrane separation system.

Embodiment 3

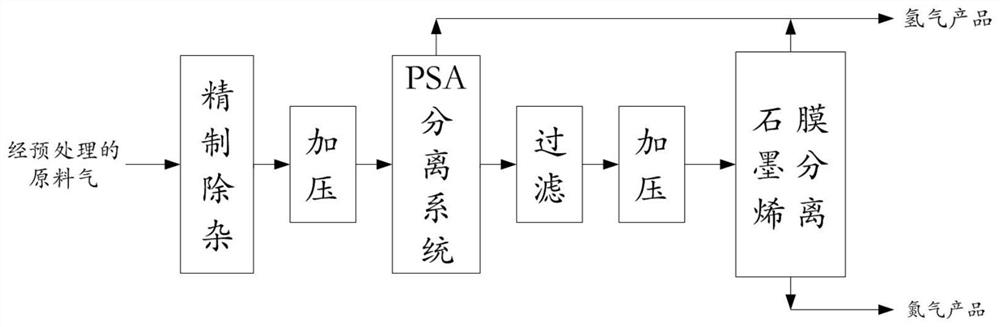

[0036] Such as image 3 As shown, on the basis of Example 1, the hydrogen-nitrogen mixture from the refining and impurity removal step is first pressurized to the pressure required for the hydrogen product to return to the MOCVD process, 3.8 to 4.0 MPa, and enters the 5 towers filled with trioxide The PSA hydrogen extraction system composed of composite adsorbents such as dialuminum, silica gel, activated carbon and molecular sieve is used for hydrogen purification. It adopts 1-tower adsorption, 2-time pressure equalization, and product gas flushing process. The purity of the outflow from the top of the adsorption tower is greater than or equal to 99.999-99.9999%. The hydrogen product, with a pressure of 3.8-4.0MPa, enters the product gas buffer tank. The desorbed gas flowing out from the bottom of the adsorption tower is pressurized to 8.0-10.0MPa after precision filtration and enters the graphene membrane separation system. The purity of the outflow from the permeate side is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com