Production process of phloretin on basis of fermentation of saccharomyces cerevisiae and saccharomyces cerevisiae

A technology of Saccharomyces cerevisiae and phloretin, applied in the direction of microorganism-based methods, fermentation, microorganisms, etc., can solve the problems of increasing the cost of phloretin and unfavorable industrial production, and achieve small market price fluctuations, low prices, and easy availability of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

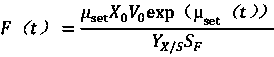

Method used

Image

Examples

Embodiment 1

[0032] This example provides a process for activating Saccharomyces cerevisiae by CM-l-u-t medium:

[0033] Thaw the frozen Saccharomyces cerevisiae with the biological deposit number CCTCC NO M2018718 and add it to the defective CM-lut medium at a rate of 1% for cultivation. The medium consists of 6.7 g of amino-free yeast nitrogen source and adenine. 50mg, 100mg histidine, 0.83g dropout powder, dissolved in ultrapure water, adjust the pH to 5.6, dilute to 950mL, autoclave, then cool to room temperature, add 50mL of an autoclaved glucose solution with a concentration of 40% , Mix well and set aside; in this experiment, 150mL of defective CM-lut medium was added to a 250mL Erlenmeyer flask that was autoclaved, and 1.5mL of Saccharomyces cerevisiae was added to activate the strain. Cultivate until the OD600 of the bacterial solution (that is, the absorbance value of the bacterial solution measured at a wavelength of 600nm) reaches 4-6, and the culture conditions: temperature 30°C,...

Embodiment 2

[0035] This example provides the YPAD medium expansion culture process:

[0036] Use a pipette to precisely pipette 10 mL of the bacterial solution in Example 1, and add it to a 2L conical flask containing 1000 mL of YPAD medium after being autoclaved at a rate of one percent. The composition is: 10 g of yeast extract, 50 mL of adenine and 20 g of peptone are dissolved in 950 ml of ultrapure water, autoclaved, and after cooling to room temperature, 50 mL of an autoclaved glucose solution with a concentration of 40% is added.

[0037] Yeast was cultured in YPAD medium, and cultivated until the OD600 of the bacterial solution reached 4.5-9. The culture conditions: temperature 30℃, rotation speed 220 r / min.

Embodiment 3

[0039] This embodiment provides a fermentation process in a fermentor:

[0040] First, in the fermentation process, take the bacterial liquid in the above example 2 for fermentation in a fermentor. The complete steps are as follows: prepare a fermentation medium. The 3000ml fermentation medium consists of 66g glucose, 45g ammonium sulfate, and potassium dihydrogen phosphate. 24g, 18.6g magnesium sulfate heptahydrate, 6g dropout powder, 30mL trace metal solution, 3mL calcium chloride dihydrate with a concentration of 2g / L, and 7.5g histidine dissolved in 2877mL ultrapure water, autoclaved and cooled to After room temperature, add 75mL of adenine aqueous solution with a concentration of 10% filtered and sterilized and 48mL of filtered and sterilized Vitamin solution (vitamin solution), mix well, and set aside. The vitamin solution is composed of: weigh 0.05 g of biotin, 1 g calcium pantothenate, 1 g niacin, 25 g inositol, 1 g thiamine, 1 g pyridoxal and 0.2 g p-aminobenzoic acid, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com