Composite water treatment agent used for treating industrial waste acid and production method of composite water treatment agent used for treating industrial waste acid

A technology for industrial waste acid and water treatment, applied in water/sewage treatment, neutralized water/sewage treatment, adsorption water/sewage treatment, etc. Achieve good solid-liquid separation performance, easy removal, and good effluent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

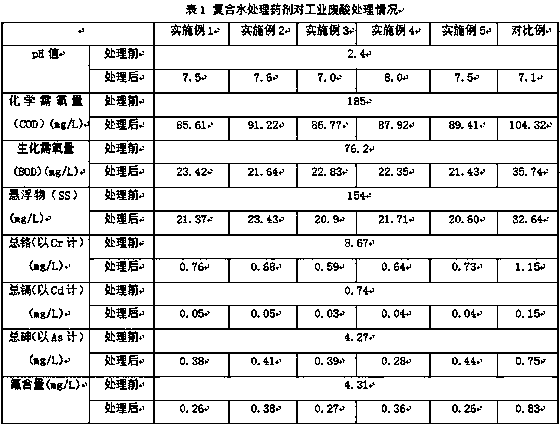

Examples

Embodiment 1

[0023] In this embodiment, the components of the composite water treatment agent and their weight-to-number ratios are: 18 parts of carbide slag, 16 parts of shell powder, 14 parts of plant ash, 14 parts of polyacrylamide, 6 parts of alkyl betaine, and Gemini quaternary ammonium salt 2 parts, 6 parts of coupling agent, 4 parts of sodium lignosulfonate, 4 parts of sodium stearate, 3 parts of polyethylene wax.

[0024] In this embodiment, the method for preparing a composite water treatment agent for industrial waste acid treatment comprises the following steps:

[0025] Step 1) Preparation of modified plant ash: Take 14 parts of plant ash and add it to a sodium hydroxide solution with a concentration of 2.5mon / L, carry out alkalization treatment at 200°C for 60min, then rinse with distilled water to remove impurities, and then put it under 50°C Carry out vacuum drying to constant weight, pulverize into 40-mesh powder, and then stir evenly with 1 part of silane coupling agent to...

Embodiment 2

[0029] In this embodiment, the components of the composite water treatment agent and their weight / number ratios are: 20 parts of carbide slag, 20 parts of shell powder, 16 parts of plant ash, 16 parts of polyacrylamide, 8 parts of alkyl betaine, 3 parts of dimethyl benzyl ammonium chloride, 8 parts of coupling agent, 5 parts of sodium lignosulfonate, 6 parts of sodium stearate, and 5 parts of polyethylene wax.

[0030] In this embodiment, the method for preparing a composite water treatment agent for industrial waste acid treatment comprises the following steps:

[0031]Step 1) Preparation of modified plant ash: Take 16 parts of plant ash and add it to a sodium hydroxide solution with a concentration of 2.5mon / L, carry out alkalization treatment at 250°C for 90min, then rinse with distilled water to remove impurities, and then heat it at 55°C Carry out vacuum drying to constant weight, pulverize into 60-mesh powder, and then stir evenly with 2 parts of titanate coupling agent ...

Embodiment 3

[0035] In this embodiment, the components of the composite water treatment agent and their weight / number ratios are: 18.5 parts of carbide slag, 19 parts of shell powder, 14.5 parts of plant ash, 15 parts of polyacrylamide, 7 parts of alkyl betaine, and Gemini quaternary ammonium salt 2.5 parts, 7.5 parts of coupling agent, 5 parts of sodium lignosulfonate, 4.5 parts of sodium stearate, 3.5 parts of polyethylene wax.

[0036] In this embodiment, the method for preparing a composite water treatment agent for industrial waste acid treatment comprises the following steps:

[0037] Step 1) Preparation of modified plant ash: Take 14.5 parts of plant ash and add it to a sodium hydroxide solution with a concentration of 2.5mon / L, carry out alkalization treatment at 230°C for 70min, then rinse with distilled water to remove impurities, and then heat it at 52°C Carry out vacuum drying to constant weight, pulverize into 45 mesh powder, and then mix with 1.5 parts of aluminate coupling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com