System and method for treating waste gas during synthesis of dimethyl sulfate

A technology for dimethyl sulfate and waste gas treatment, which is applied in gas treatment, combustion methods, separation methods, etc., can solve the problems of waste gas without reasonable and suitable treatment methods, corroded equipment and pipelines, and a large amount of waste lye, etc., and achieve economic benefits And environmental protection benefits are obvious, the equipment has no corrosion, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

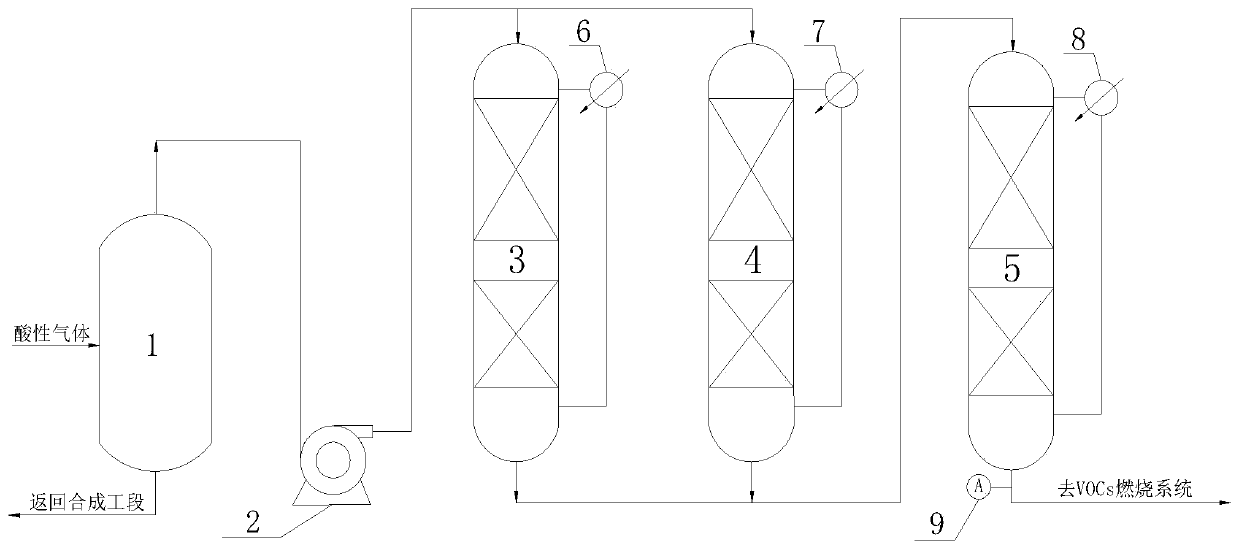

[0034] A waste gas treatment system in the synthesis of dimethyl sulfate, which includes a gas-liquid phase separation tank 1, an induced draft fan 2, a first-level absorption tower 3, a second-level absorption tower 4, a second-level absorption tower 5, a first Heater 6, the second heat exchanger 7, the 3rd heat exchanger 8, acid gas concentration detector 9 and VOCs catalytic combustion system; Described gas-liquid phase separation tank 1 is used for producing in the synthesis of dimethyl sulfate containing The waste gas of water is separated into gas phase and liquid phase; after the first-level absorption tower 3 and the second-level absorption tower 4 are connected in parallel, the top of the gas-liquid phase separation tank 1 is connected through the induced draft fan 2, for separating the gas-liquid phase The gas separated in the tank 1 is transported from the top of the gas-liquid phase separation tank 1 through the induced draft fan 2 to carry out the adsorption treatm...

Embodiment 2

[0036] A kind of preparation of macroporous weakly basic anion exchange resin comprises the following steps:

[0037] S11: Preparation of polymerized white balls, the initiator azobisisobutyronitrile (AIBN), monomer styrene, crosslinking agent divinylbenzene, porogen n-butanol, and dispersant polyvinyl alcohol are formed by liquid phase suspension polymerization Polymerized white balls with a particle size distribution of 1 to 4 mm, in which the concentration of the dispersant is 0.01 to 0.1 wt %; the mass ratio of the crosslinking agent to the monomer is 1:3 to 8; the polymerization is carried out in stages: firstly, the temperature is raised from room temperature to 75°C, suspend polymerization at 75°C for 2 hours, then raise the temperature to 90°C, and polymerize at 90°C for 2 hours;

[0038] S12: Chloromethylation reaction, the alkylation reagent chloromethyl ether and the above-mentioned polymerized white balls are mixed according to the mass ratio of 3-5:1, reacted at 3...

Embodiment 3

[0042] A kind of processing method of waste gas in the synthesis of dimethyl sulfate, it uses the waste gas treatment system in the synthesis of dimethyl sulfate of embodiment 1, and the macroporous weakly basic anion exchange resin prepared by embodiment 2 is loaded on the first stage In absorption tower 3, second one level absorption tower 4 and secondary absorption tower 5, comprise the following steps:

[0043] S1. The waste gas from the production workshop is sent to the gas-liquid phase separation tank 1 to separate the gas phase and the liquid phase. The separated liquid phase with a mass of about 2% returns to the synthesis section through the liquid phase pipeline; the separated gas phase enters the subsequent The absorption tower, the gas phase contains about 0.5% SO by mass 2 Gas, organic gas with about 0.1% moisture and 2% moisture, and the rest is air;

[0044] S2: The waste gas separated from the gas and liquid in step S1 is transported to the first-level absorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com