Preparation method of electro-catalytic material, electro-catalytic material and application of electro-catalytic material

An electrocatalytic material and hydrothermal reaction technology, applied in the field of electrochemistry, can solve the problems of low efficiency and low activity of electrolyzed water, achieve strong activity and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

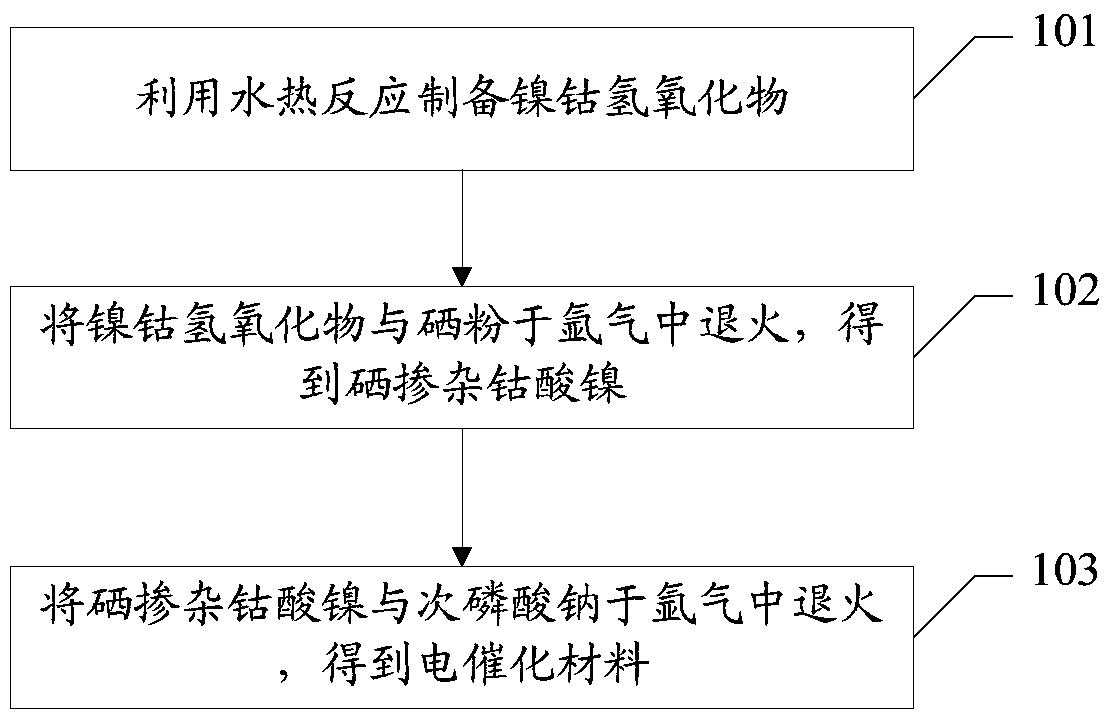

[0032] The first aspect of the present application provides a method for preparing an electrocatalytic material, the method comprising:

[0033] Step 101, using hydrothermal reaction to prepare nickel-cobalt hydroxide;

[0034] Step 102, annealing nickel-cobalt hydroxide and selenium powder in argon to obtain selenium-doped nickel cobaltate;

[0035] Step 103, annealing the selenium-doped nickel cobaltate and sodium hypophosphite in argon to obtain an electrocatalytic material.

[0036] Specifically, the preparation of nickel-cobalt hydroxide by hydrothermal reaction in step 101 includes:

[0037] Soluble nickel salt, soluble cobalt salt, ammonium fluoride and hexamethylenetetramine are dissolved in the solvent according to the molar ratio of 5:10:20:2 to obtain the first solution, the solvent is ethanol and water volume ratio 1: 1 mixed solution;

[0038] The first solution was heated at 140°C for 8 hours, cooled to room temperature, washed with water, washed with alcohol ...

Embodiment 1

[0052] Embodiment 1: Preparation of nickel cobalt oxide spinel structure

[0053] (1) Put the hydrothermal solution containing ammonium fluoride, nickel ions, cobalt ions and hexamethylenetetramine into the polytetrafluoroethylene liner. The composition of the hydrothermal solution is: 15ml deionized water, 15ml ethanol, 0.1244g nickel acetate hexahydrate, 0.219g cobalt acetate hexahydrate, 0.074g ammonium fluoride and 0.033g hexamethylenetetramine. Then place the polytetrafluoroethylene liner in a stainless steel autoclave and seal it, heat it in an electric blast drying oven at a temperature of 140°C for 8 hours, then cool it to room temperature, wash it with water, wash it with alcohol and dry it;

[0054] (2) Place the nickel-cobalt hydroxide prepared in step (1) separately in a tube furnace, anneal and heat in an argon atmosphere to obtain a nickel cobalt oxide spinel structure; the process parameters are: annealing temperature 400 ° C, heat preservation Time 2h.

[005...

Embodiment 2

[0056] Example 2: Preparation of selenium-doped nickel cobalt oxide structure

[0057] (1) Put the hydrothermal solution containing ammonium fluoride, nickel ions, cobalt ions and hexamethylenetetramine into the polytetrafluoroethylene liner. The composition of the hydrothermal solution is: 15ml deionized water, 15ml ethanol, 0.1244g nickel acetate hexahydrate, 0.219g cobalt acetate hexahydrate, 0.074g ammonium fluoride and 0.033g hexamethylenetetramine. Then place the polytetrafluoroethylene liner in a stainless steel autoclave and seal it, heat it in an electric blast drying oven at a temperature of 140°C for 8 hours, then cool it to room temperature, wash it with water, wash it with alcohol and dry it;

[0058] (2) the nickel-cobalt hydroxide prepared by step (1) and the selenium powder are placed in a tube furnace at a mass ratio of 1:5, the selenium powder is placed on the upstream of the tube furnace atmosphere, and the nickel-cobalt hydroxide is downstream, Annealing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com