Photo-Fenton desulfurization-denitration catalyst and preparation method thereof

A desulfurization, denitrification and catalyst technology, which is applied in the field of flue gas purification, can solve the problems of high investment and operation costs, low commercial value, and large floor area, and achieve the effects of improving desulfurization and denitrification performance, increasing utilization rate, and improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] (1) Wash 70 g of ceramic foam three times with deionized water, and dry at 100 °C for later use.

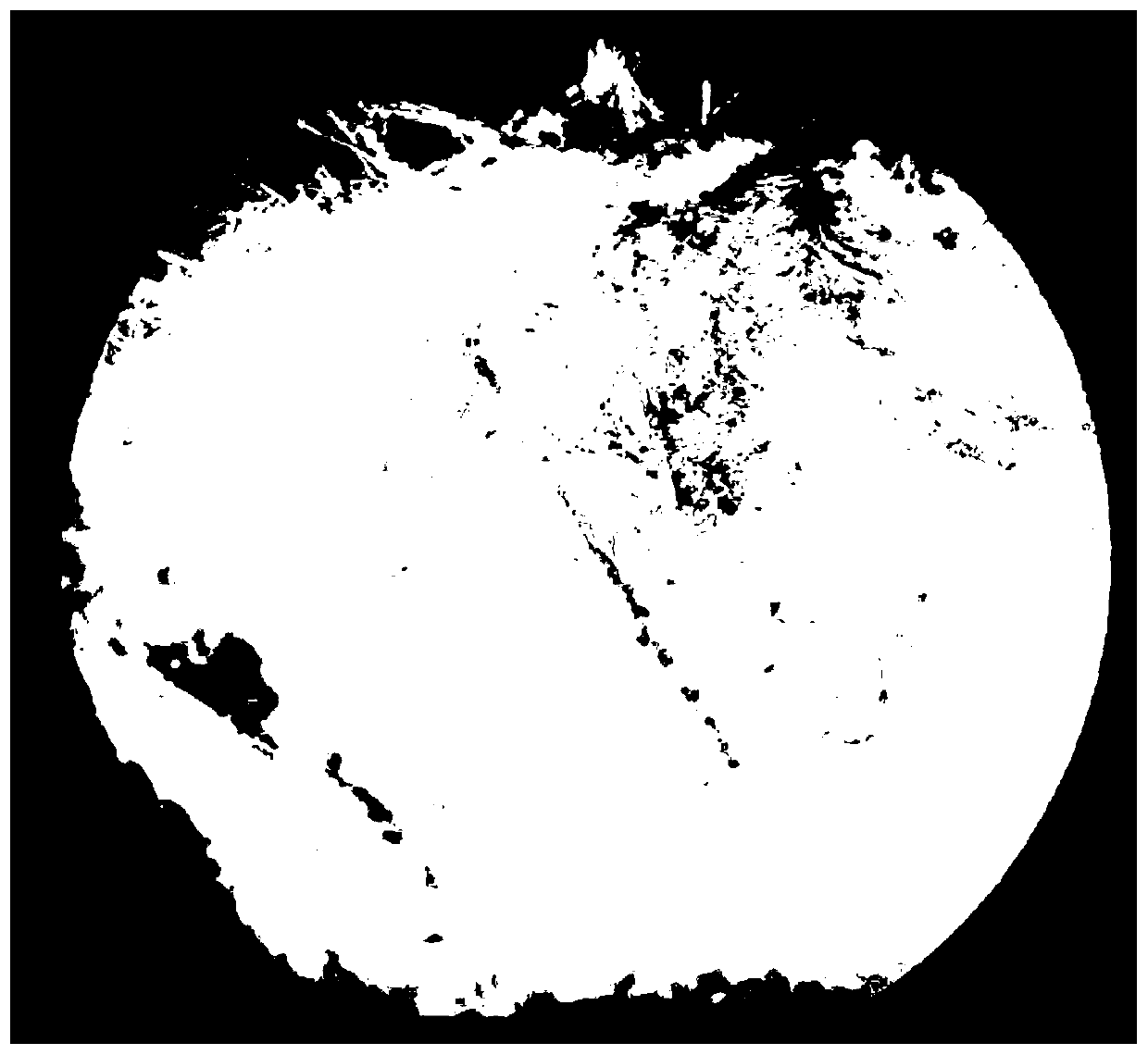

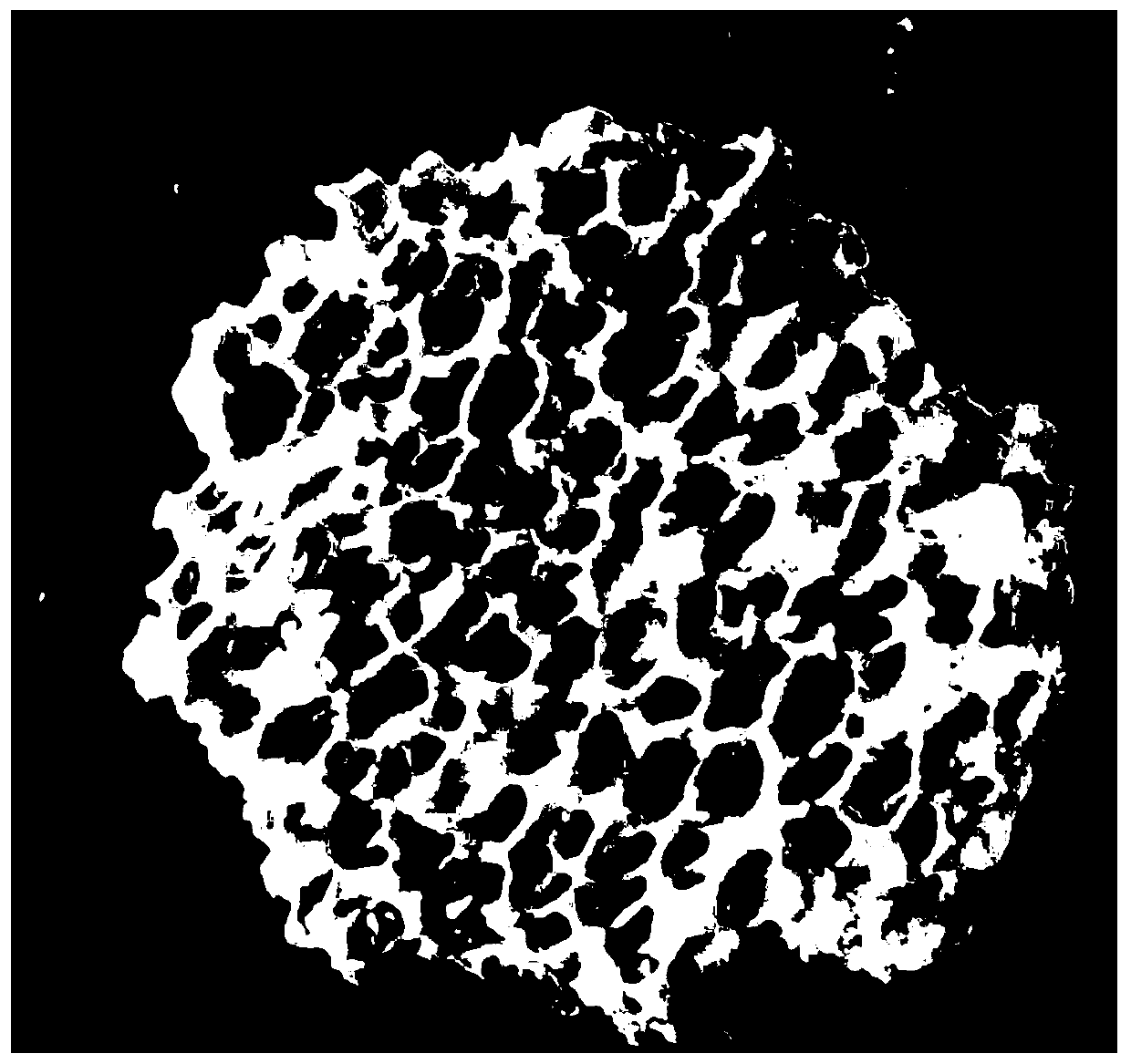

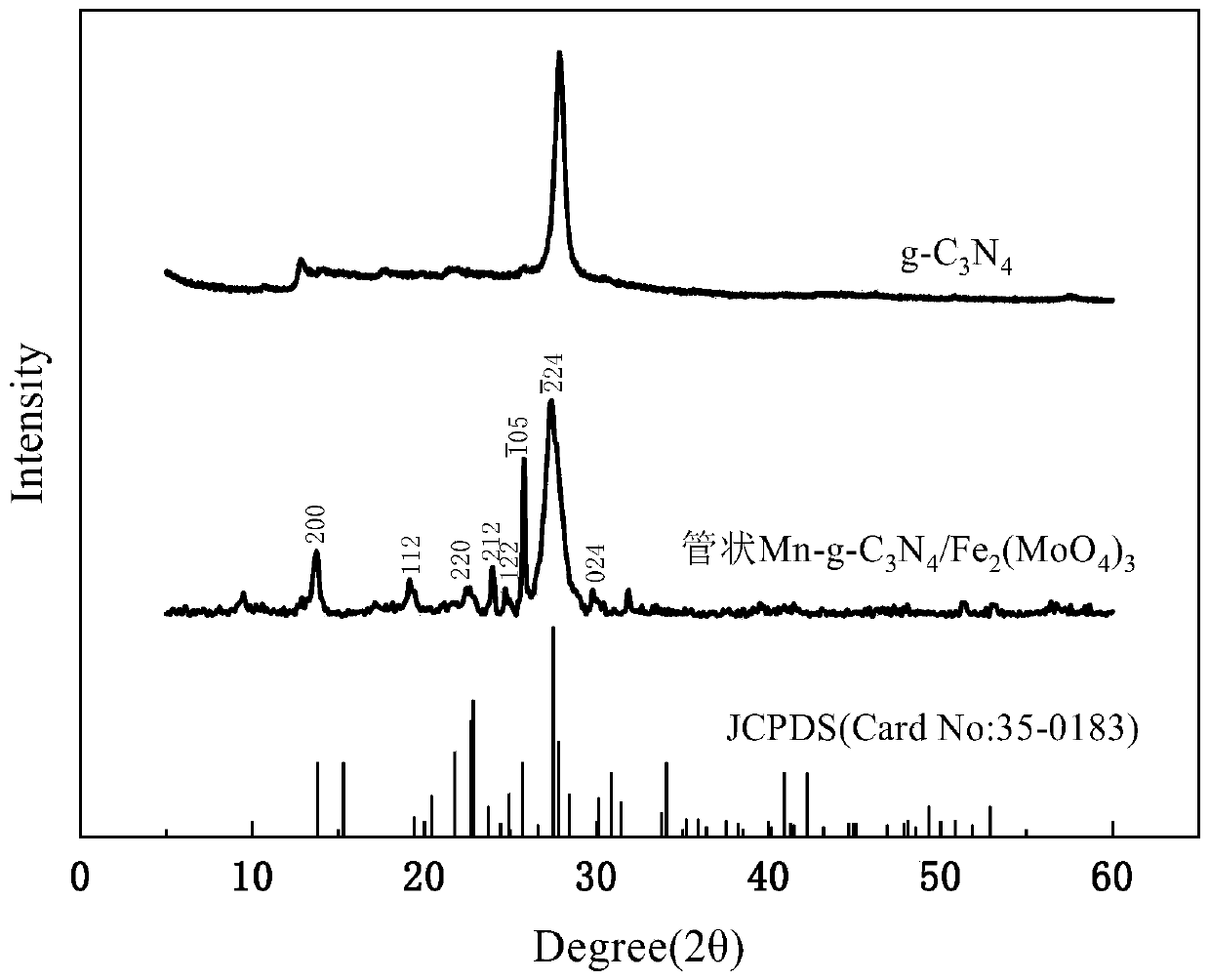

[0076] (2) Add 1g of melamine into 30ml of ethylene glycol solvent, stir at 60°C until the melamine is completely dissolved, add 0.05g of manganese nitrate and 60ml of 0.15mol / L dilute nitric acid solution after the solution is cooled, and wash the resulting precipitate with ethanol, Suction filtration, drying at 60°C, calcination at 520°C for 2h (heating rate 10°C / min), the obtained sample is tubular Mn-g-C 3 N 4 , which looks like figure 1 shown. from figure 1 As can be seen in the tubular Mn-g-C 3 N 4 It has an ultra-high aspect ratio, and the overall shape is complete, the surface is smooth, and the thickness is uniform. Compared with the flake g-C obtained by ordinary thermal condensation polymerization 3 N 4 , the specific surface area has been greatly improved, which increases the number of surface active sites, which is conducive to improving the efficiency ...

Embodiment 2

[0090] (1) Wash 70 g of ceramic foam three times with deionized water, and dry at 100 °C for later use.

[0091] (2) Add 1g of melamine into 30ml of ethanol solvent, stir at 60°C until the melamine is completely dissolved, add 0.05g of manganese chloride and 60ml of 0.15 mol / L dilute nitric acid solution after the solution is cooled, wash the resulting precipitate with ethanol, pump Filter, dry at 60°C, and roast at 520°C for 2h (heating rate: 10°C / min).

[0092] (3) Weigh 0.22 g of ammonium molybdate tetrahydrate and dissolve it in 30 ml of deionized water, weigh 0.34 g of ferric nitrate nonahydrate and dissolve it in 30 ml of deionized water, and add the ferric nitrate solution dropwise to the ammonium molybdate solution under stirring After the dropwise addition, the pH was adjusted to 5 with ammonia water to generate the iron molybdate precursor.

[0093] (4) The tubular Mn-g-C 3 N 4 Add it to the ferric molybdate precursor, stir for 3 hours, transfer it to a 100 ml hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com