Quantum dot fluorescent nanosphere based on amphiphilic silicon carrier, and preparation method thereof

A fluorescent nanometer and quantum dot technology, which is applied in nanotechnology, nanotechnology, nano-optics, etc. for materials and surface science, can solve the cumbersome preparation process of quantum dot fluorescent nanospheres, poor controllability of size and particle size distribution, Fluorescence intensity is easy to lose and other problems, to achieve the effects of controllable quantum dot coating amount and size, scaling size, quantum dot coating amount, and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

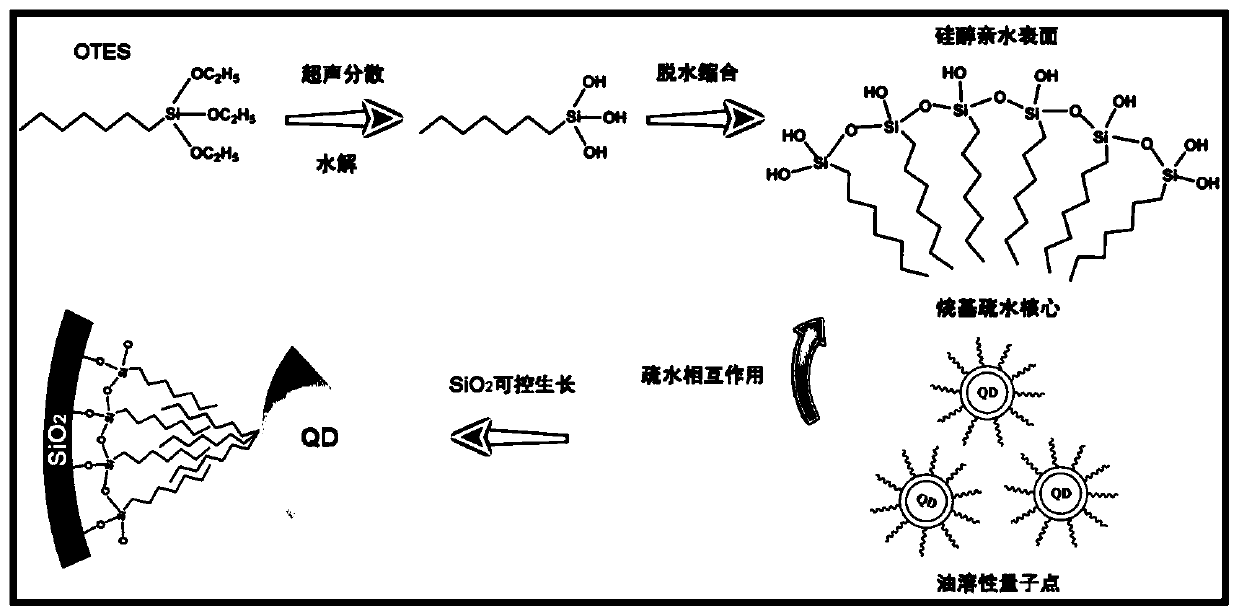

Method used

Image

Examples

Embodiment 1

[0040] (1) Take 750 μL of cadmium selenide / zinc sulfide quantum dot stock solution (2.1×10 - 5 mol / L), an equal volume of methanol was added to precipitate quantum dots. Discard the supernatant after centrifugation, dry the precipitate slightly in the air, then add 40 μL of n-octyltriethoxysilane, and fully dissolve to obtain an orange transparent solution, which is the quantum dot-organosilane precursor;

[0041] (2) Transfer the quantum dot-organosilane precursor to a glass bottle, add 40mL water and 60μL ammonia water (28wt%); extend the ultrasonic probe (diameter 6mm) below the liquid surface, set the amplitude to 30%, and 5s ultrasonication / 3s pause is the working cycle, ultrasonic treatment for 1h, to obtain quantum dot micellar solution;

[0042] (3) Filter the quantum dot micellar solution through a 0.22 μm microporous membrane, add 1.6 mL of sodium silicate solution (0.54 wt%), stir and react for 24 hours, and prepare CdSe / ZnS@SiO with a diameter of 25 nm 2 Crude s...

Embodiment 2

[0045] The difference between Example 2 and Example 1 is that step (4) is added: use an ultrafiltration centrifuge tube to concentrate the above-mentioned CdSe / ZnS@SiO 2 A crude solution of fluorescent nanospheres until the absorbance of the quantum dots (at the position of its exciton absorption peak) reaches about 0.1. Then, 3 mL of the above solution was added to 12 mL of ethanol, 0.2 mL of ammonia water and 15 μL of tetraethyl orthosilicate mixed solution, slowly stirred and reacted for 6 hours to coat the silica layer, and the CdSe / ZnS@ SiO 2 Quantum dot fluorescent nanospheres.

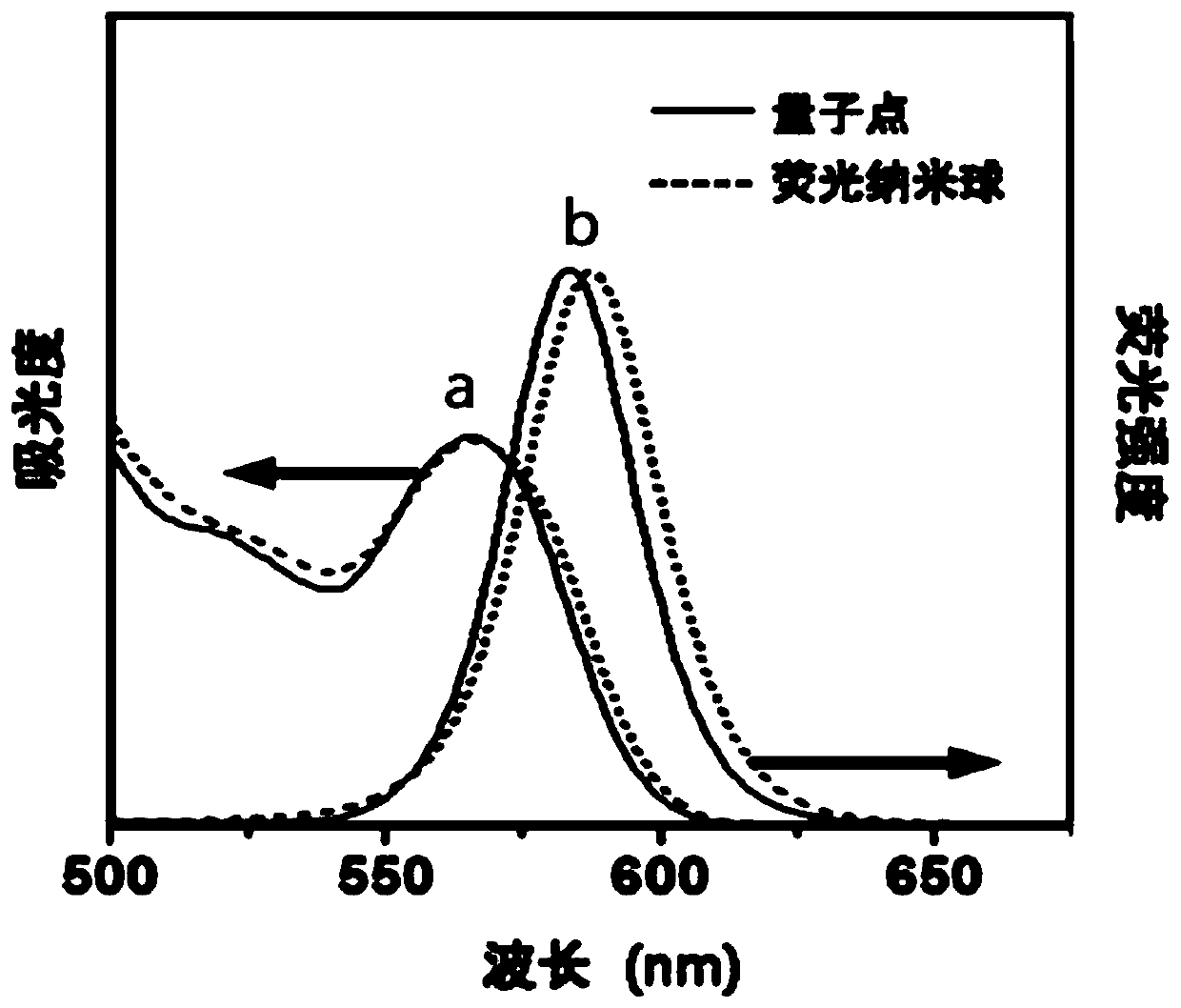

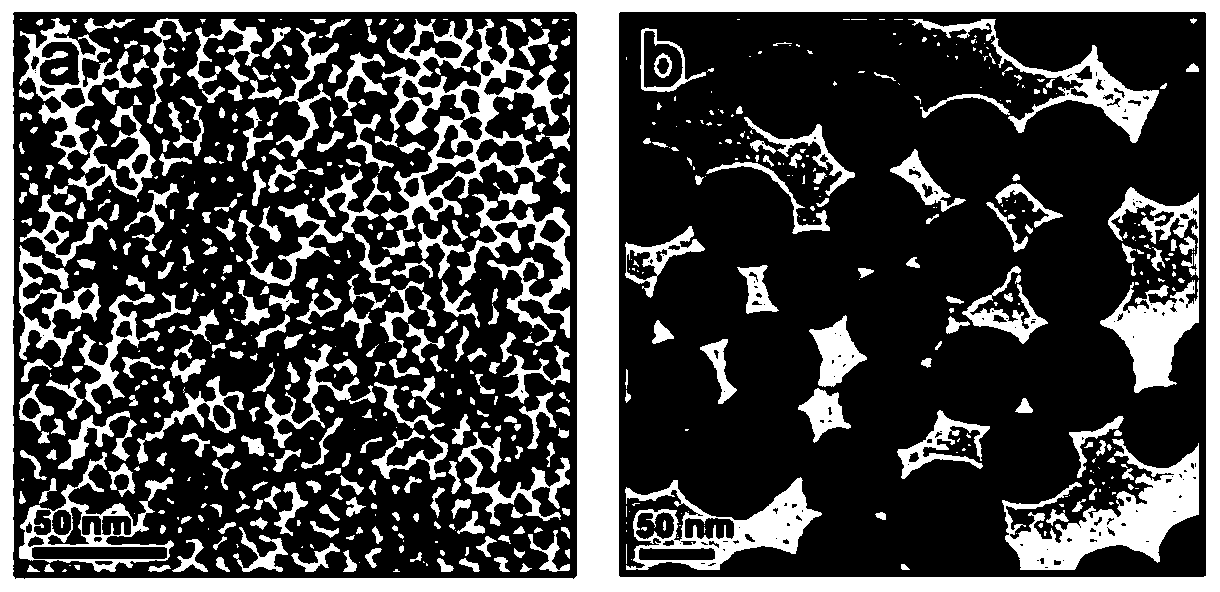

[0046] image 3 It is CdSe / ZnS@SiO after oil-soluble cadmium selenide / zinc sulfide quantum dots (a) and the grown silica shell layer obtained in Example 2 2 The transmission electron microscope image of quantum dot fluorescent nanospheres (b), it can be seen that the oil-soluble cadmium selenide / zinc sulfide quantum dots with uniform particle size and good monodispersity are modified by amphi...

Embodiment 3

[0048] (1) Take 400 μL of cadmium selenide / zinc sulfide quantum dot stock solution (2.1×10 - 5 mol / L), an equal volume of methanol was added to precipitate quantum dots. Discard the supernatant after centrifugation, dry the precipitate slightly in the air, then add 40 μL of n-octyltriethoxysilane, and fully dissolve to obtain an orange transparent solution, which is the quantum dot-organosilane precursor;

[0049] (2) Transfer the quantum dot-organosilane precursor to a glass bottle, add 40 mL of water and 60 μL of ammonia water (28 wt%). Extend the ultrasonic probe (diameter 6mm) below the liquid surface, set the amplitude to 30%, use 5s ultrasonication / 3s pause as the working cycle, and ultrasonically treat for 1h to obtain the quantum dot micellar solution;

[0050] (3) Filter the quantum dot micellar solution through a 0.22μm microporous membrane, add 1.6mL sodium silicate solution (0.54wt%), stir and react for 24h, and obtain CdSe / ZnS@SiO with a diameter of 16nm 2 crud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com