Preparation method and applications of flower-like ferroferric oxide-molybdenum disulfide-manganese dioxide nano-complex

A technology of triiron tetroxide and nanocomposite, which is applied in the directions of iron oxide/iron hydroxide, molybdenum sulfide, ferrous iron oxide, etc., can solve the problems of small specific surface area and low activity of molybdenum disulfide, etc. Effect of simplicity, low cost, and superior nitrite properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (1) Weigh 30 grams of ferric chloride hexahydrate and 15 grams of ferric sulfide in 250 ml of deionized water, inject nitrogen gas for 20 minutes and stir until transparent;

[0070] (2) Stir the mixed solution obtained in step (1) at 60°C for 5 minutes, add ammonia water, and age at 70°C for 30 minutes to obtain ferric oxide;

[0071] (3) Weigh 0.3g sodium molybdate and 0.4g thiourea respectively in deionized water and stir evenly;

[0072] (4) Weigh 0.4 g of the ferric oxide obtained in step (3), stir at room temperature for 40 minutes, transfer to an autoclave, and react at 200 °C for 24 hours;

[0073] (5) After centrifuging the reaction product of step (4) to remove water, first wash with ethanol to remove unreacted organic matter, then wash with deionized water to remove unreacted inorganic ions, and place the cleaned reaction product in an oven drying at 70°C to obtain ferric oxide-molybdenum disulfide nanocomposites;

[0074] (6) Weigh 0.5g of manganese sulfat...

Embodiment 2

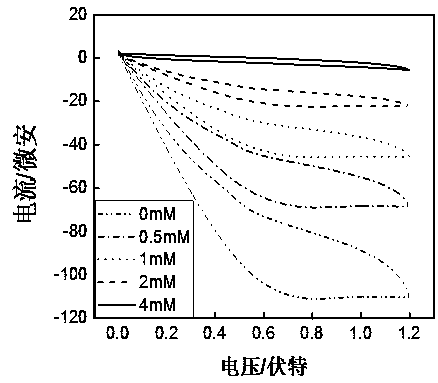

[0083] The three-electrode system prepared in Example 1 was placed in a place not containing and containing 0.5, 1, 2, 4 mmol dm -3 0.1 mol dm of sodium nitrite -3 In the phosphate buffer solution, the catalytic performance of the ferric oxide-molybdenum disulfide-manganese dioxide complex to nitrite was determined by cyclic voltammetry, the cyclic voltammetry diagram is as follows figure 2 shown.

[0084] figure 2 Modified glassy carbon electrodes for ferric oxide-molybdenum disulfide-manganese dioxide composites without and with 0.5, 1, 2, 4 mmol dm -3 0.1 mol dm of sodium nitrite -3 Cyclic voltammogram in phosphate buffer solution. It can be seen from the figure that when the composite-modified glassy carbon electrode was moved from the phosphate buffer solution to the solution containing sodium nitrite, an oxidation peak appeared near 0.7V, and with the increase of the nitrite concentration, the peak current increases. This result indicated that the reduction react...

Embodiment 3

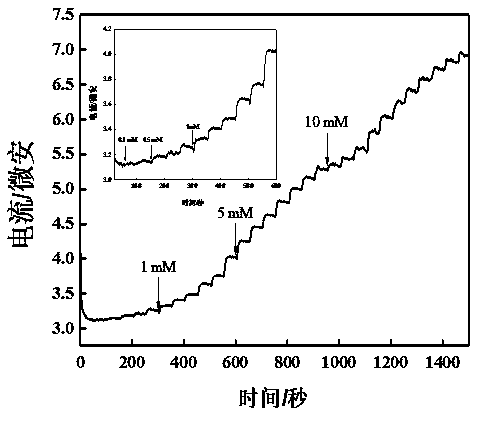

[0087] The three-electrode system prepared in Example 1 was placed in a 0.1 mol dm -3 In the phosphate buffer solution, sodium nitrite solutions of different concentrations were added dropwise, and the response current values corresponding to the sodium nitrite solutions of different concentrations were respectively measured by the constant potential method, and the linear relationship diagram between the concentration of nitrite and the response current was obtained ( image 3 );

[0088] From image 3 It can be seen in the figure that the glassy carbon electrode pair of ferric oxide-molybdenum disulfide-manganese dioxide composite modified 0.1mmoldm -3 Any nitrite can respond. Figure 4 is true image 3 The graph of nitrite concentration and response current. It can be seen from the figure: in the range of 5.0 to 3400µmol dm -3 A good linear relationship is maintained in the range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com