Preparation method of polyvinyl alcohol cellulose composite solid gum

A technology of polyvinyl alcohol and solid glue, which is applied in the preparation of cellulose adhesives, animal glue or gelatin, ester copolymer adhesives, etc., can solve the problem that the bonding performance and storage stability need to be improved, and cannot fundamentally Improve mutual solubility, solid glue does not have environmental protection performance and other problems, to achieve the effect of not easy to deform, reduce hardness, not easy to soften

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

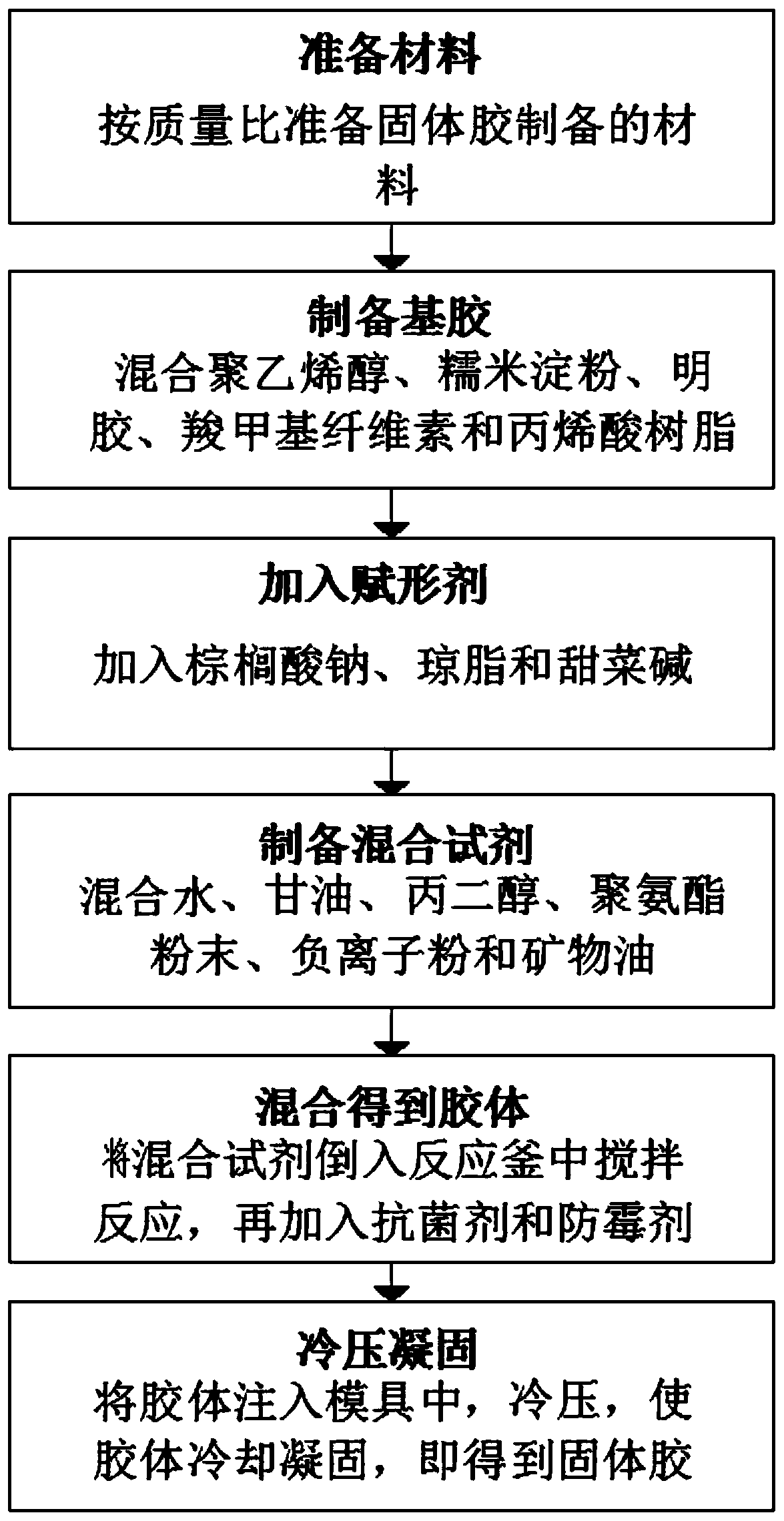

[0028] according to figure 1 As shown, the present embodiment provides a preparation method of polyvinyl alcohol cellulose composite solid glue, comprising the following steps:

[0029] Step 1: Prepare materials

[0030] Prepare materials according to mass ratio: 200 parts of water, 10 parts of polyvinyl alcohol, 15 parts of glutinous rice starch, 20 parts of gelatin, 4 parts of carboxymethyl cellulose, 10 parts of acrylic resin, 10 parts of sodium palmitate, 20 parts of agar, 20 parts of beet Alkali, 35 parts of glycerin, 25 parts of propylene glycol, 0.5 parts of defoamer, 0.5 parts of neutralizer, 0.1 part of polyurethane, 1 part of negative ion powder, 0.6 parts of heat stabilizer, 2 parts of mineral oil, 0.4 parts of silver-loaded zirconium hydroxyphosphate nano Antibacterial agent and 0.2 part of antifungal agent, wherein, defoamer is emulsified silicone oil, neutralizer is sodium hydroxide aqueous solution, heat stabilizer is ferric oxide;

[0031] Step 2: Prepare bas...

Embodiment 2

[0042] according to figure 1 As shown, the present embodiment provides a preparation method of polyvinyl alcohol cellulose composite solid glue, comprising the following steps:

[0043] Step 1: Prepare materials

[0044]Prepare materials according to mass ratio: 250 parts of water, 12 parts of polyvinyl alcohol, 18 parts of glutinous rice starch, 22 parts of gelatin, 5 parts of carboxymethyl cellulose, 11 parts of acrylic resin, 17 parts of sodium palmitate, 25 parts of agar, 22 parts of beet Alkali, 38 parts of glycerin, 28 parts of propylene glycol, 0.6 parts of defoamer, 0.7 parts of neutralizer, 0.2 parts of polyurethane, 1.5 parts of negative ion powder, 0.7 parts of heat stabilizer, 2.5 parts of mineral oil, 0.5 parts of silver-loaded zirconium hydroxyphosphate nano Antibacterial agent and 0.25 part of antifungal agent, wherein, defoaming agent is high carbon alcohol fatty acid ester complex, neutralizing agent is potassium hydroxide aqueous solution, heat stabilizer is...

Embodiment 3

[0056] according to figure 1 As shown, the present embodiment provides a preparation method of polyvinyl alcohol cellulose composite solid glue, comprising the following steps:

[0057] Step 1: Prepare materials

[0058] Prepare materials according to mass ratio: 300 parts of water, 15 parts of polyvinyl alcohol, 20 parts of glutinous rice starch, 25 parts of gelatin, 6 parts of carboxymethyl cellulose, 12 parts of acrylic resin, 18 parts of sodium palmitate, 30 parts of agar, 25 parts of beet Alkali, 40 parts of glycerin, 30 parts of propylene glycol, 0.7 parts of defoamer, 1 part of neutralizer, 0.3 parts of polyurethane, 2 parts of negative ion powder, 0.8 parts of heat stabilizer, 3 parts of mineral oil, 0.7 parts of silver-loaded zirconium hydroxyphosphate nano Antibacterial agent and 0.3 part of antifungal agent, wherein, defoamer is emulsified silicone oil, neutralizer is ammonium hydroxide aqueous solution, heat stabilizer is titanium dioxide;

[0059] Step 2: Prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com