Fat emulsion, compound amino acid and glucose injection and preparation method thereof

A glucose injection and compound amino acid technology, applied in emulsion delivery, pharmaceutical formula, transportation and packaging, etc., can solve the problems of increasing the economic burden of patients, increasing medical costs, and waste of medical resources, so as to achieve a reasonable proportion and reduce waste , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The total volume of each bag of injection in this embodiment is 900mL, wherein, in each bag of injection, the fat emulsion injection is 159mL, the glucose injection is 553mL, and the compound amino acid injection is 188mL. The fat emulsion, amino acid and The preparation method of glucose injection, comprises the steps:

[0031] Step 1. Bag making

[0032] Take the plastic film for the inner bag, press it on the bag-making hot press and connect the filling port; take the plastic film for the outer bag, press it on the bag-making hot press, and leave one side open.

[0033] Step two, dosing

[0034] Fat emulsion injection, compound amino acid injection and glucose injection were prepared on different preparation equipment.

[0035] (1) Preparation of fat emulsion injection

[0036] Take 31.8 grams of purified soybean oil, 1.91 grams of refined lecithin, 3.50 grams of anhydrous glycerin, an appropriate amount of sodium hydroxide, and 119.25 grams of water for injection...

Embodiment 2

[0052] Step two, dosing

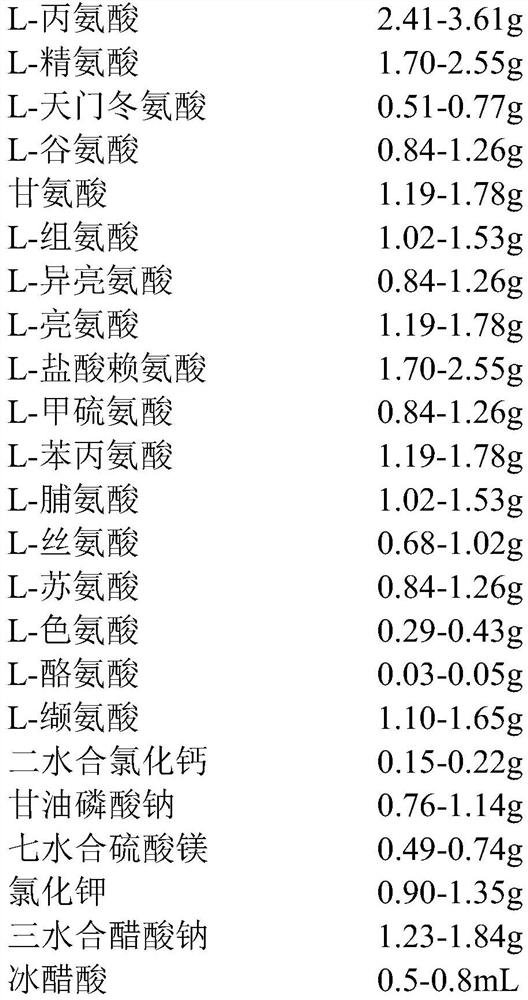

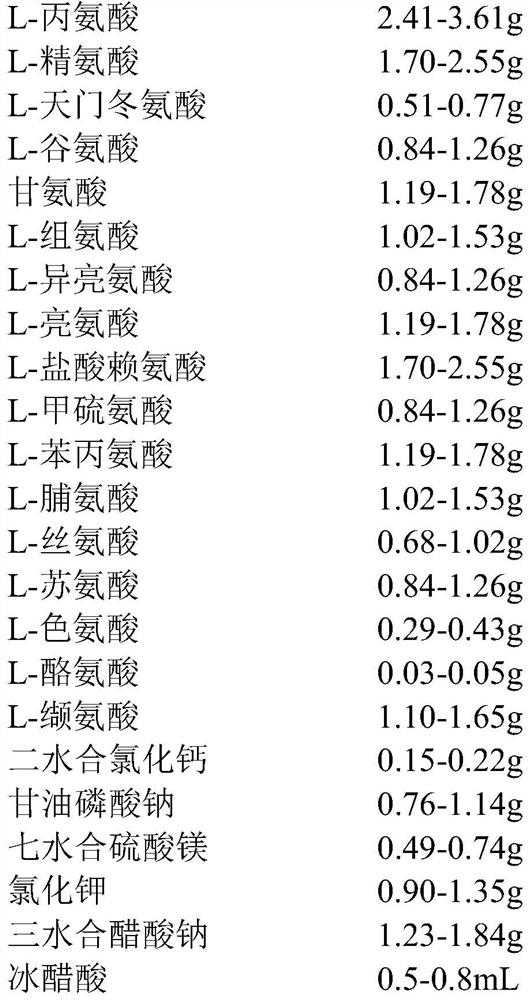

[0053] (2) The compound amino acid injection adopts the following formula: get the following raw materials, L-alanine 3.61g, L-arginine 2.55g, L-aspartic acid 0.77g, L-glutamic acid 1.26g, Glycine 1.78g, L-Histidine 1.53g, L-Isoleucine 1.26g, L-Leucine 1.78g, L-Lysine Hydrochloride 2.55g, L-Methionine 1.26g, L-Benzene Alanine 1.78g, L-proline 1.53g, L-serine 1.02g, L-threonine 1.26g, L-tryptophan 0.43g, L-tyrosine 0.05g, L-valine 1.65 g, calcium chloride dihydrate 0.22g, sodium glycerophosphate anhydrous 1.14g, magnesium sulfate heptahydrate 0.74g, potassium chloride 1.35g, sodium acetate trihydrate 1.84g, an appropriate amount of glacial acetic acid, add the above raw materials Prepare 188mL injection solution in water for injection at 80°C, stir until dissolved under nitrogen protection, and the dissolved oxygen concentration in the solution shall not be higher than 1ppm.

[0054] All the other steps, formula are identical with embodiment one.

Embodiment 3

[0056] Step two, dosing

[0057] (2) The compound amino acid injection adopts the following formula: get the following raw materials, L-alanine 3.01g, L-arginine 2.12g, L-aspartic acid 0.64g, L-glutamic acid 1.05g, Glycine 1.49g, L-Histidine 1.28g, L-Isoleucine 1.05g, L-Leucine 1.49g, L-Lysine Hydrochloride 2.12g, L-Methionine 1.05g, L-Benzene Alanine 1.49g, L-proline 1.28g, L-serine 0.85g, L-threonine 1.05g, L-tryptophan 0.36g, L-tyrosine 0.04g, L-valine 1.37 g, calcium chloride dihydrate 0.18g, sodium glycerophosphate anhydrous 0.95g, magnesium sulfate heptahydrate 0.62g, potassium chloride 1.12g, sodium acetate trihydrate 1.54g, appropriate amount of glacial acetic acid. Add the above-mentioned raw materials into 80°C water for injection that has been deoxygenated in advance to make 188mL injection, and stir until dissolved under the protection of nitrogen. The dissolved oxygen concentration in the liquid should not be higher than 1ppm.

[0058] All the other steps, formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com