Preparation method of a solvent-resistant charged composite nanofiltration membrane

A composite nanofiltration membrane and solvent-resistant technology, applied in the field of composite materials, can solve the problems that the performance needs to be further improved, the composite structure has less solvent-resistant nanofiltration membranes, etc., and achieves improved solvent resistance, good swelling resistance, and high retention rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

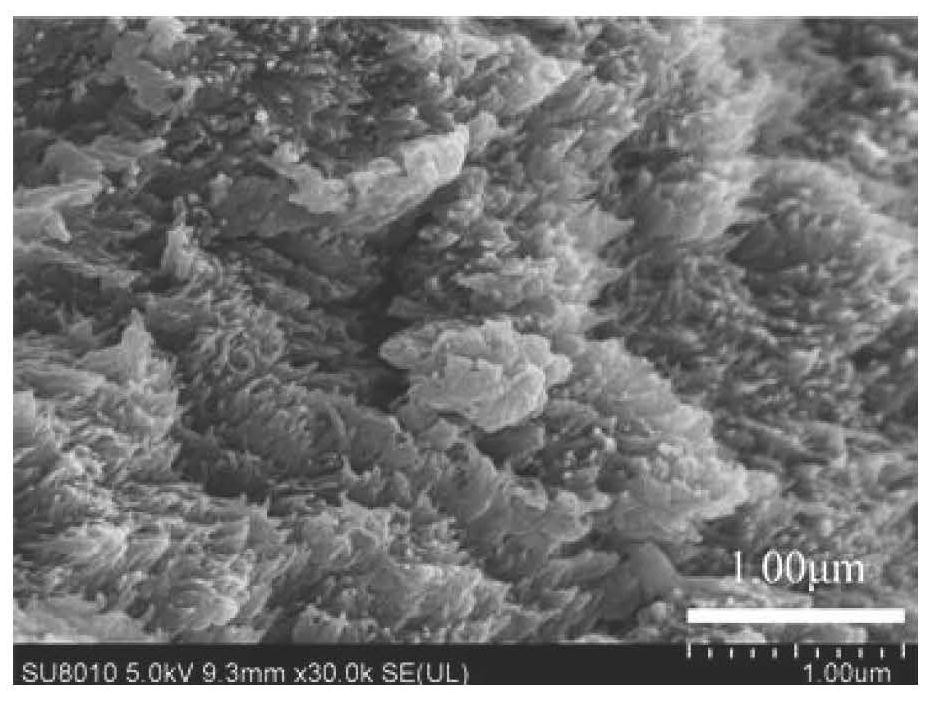

[0030] (1) Dissolution of Kevlar aromatic polyamide fiber

[0031] Dissolve 2.0 g of strong base KOH in 40 g of a mixed solvent of dimethyl sulfoxide (DMSO): water (40:1 by volume). Add 2.0 grams of Kevlar aromatic polyamide fiber to the above solution, and then mechanically stir for 2 weeks at room temperature to destroy a large number of hydrogen bonds between the carbonyl and amide groups between the molecules until its color becomes a uniform dark red nanofiber solution . The obtained nanofiber solution was left to stand for 30 days to further hydrolyze the amide into short polymer chain segments to obtain an amino group-containing nanofiber dispersion, in which the molecular chain length of the nanofibers was tested to be 15-65nm.

[0032] (2) Preparation of ion-pair structure ionic liquid monomer

[0033] 6.52g NaHCO 3 Add 124mL of water / acetone (1:1, v / v) mixed solvent into a round bottom flask. After dissolving, 16.9g of imidazole and 62.33mg of hydroquinone were ad...

Embodiment 2

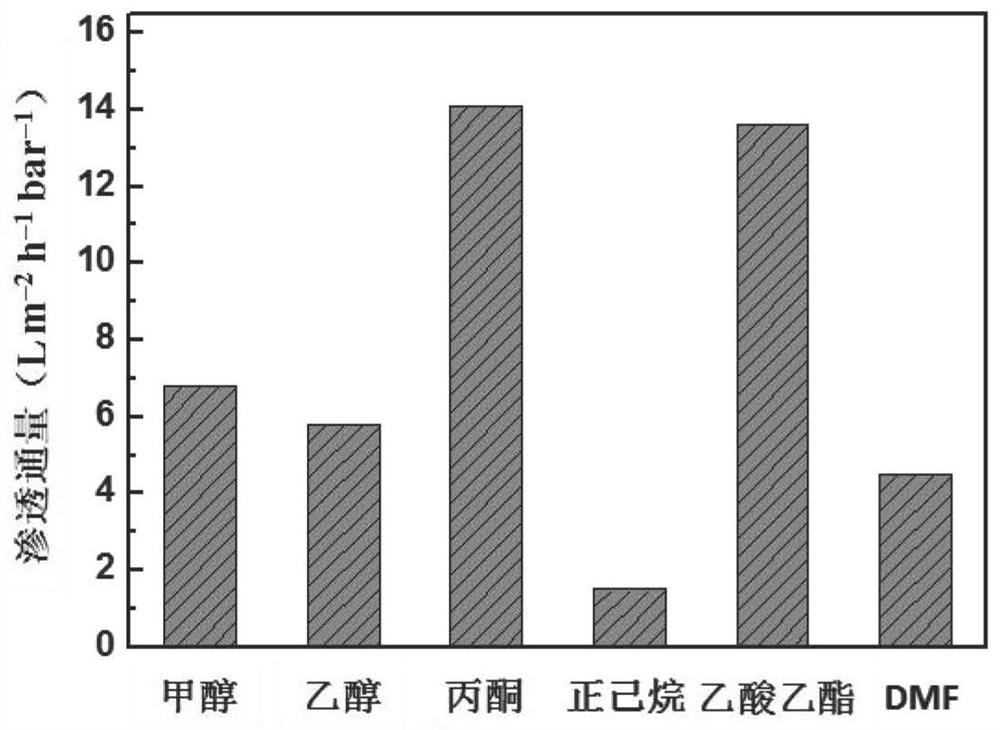

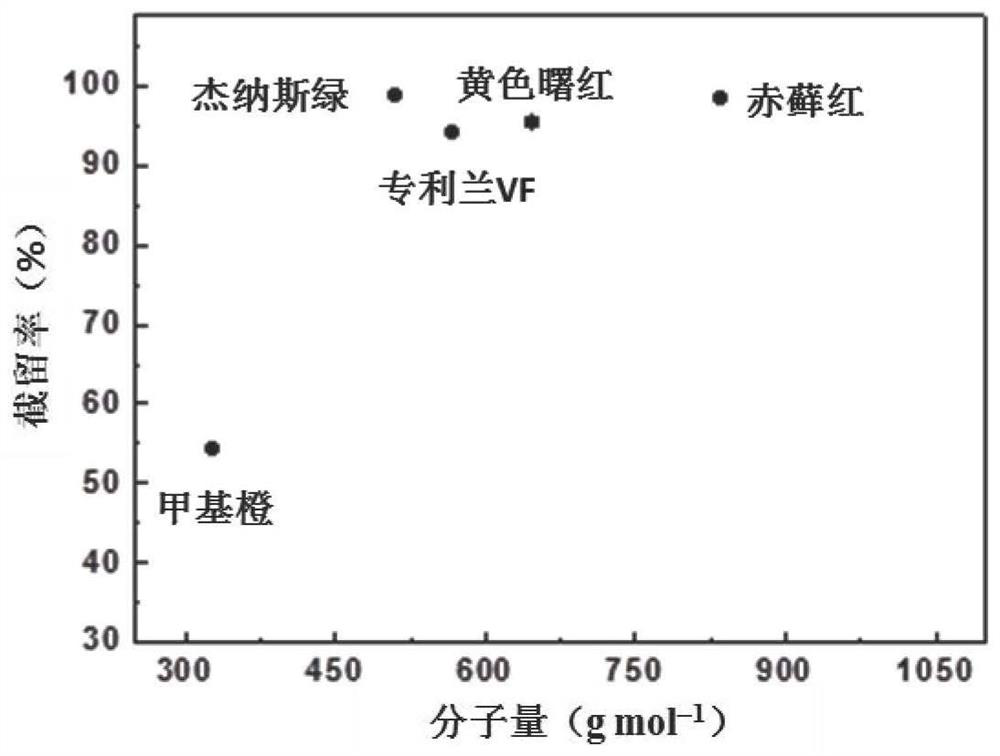

[0049] In embodiment 1 step (5), the mass concentration 1.0wt% of GO-[VBzImIBa][Br] is changed to 1.5wt%, and other conditions remain unchanged. A composite structure solvent-resistant nanofiltration membrane with a thickness of 129 μm was obtained. Using the performance testing method described in Example 1, the solvent resistance of the nanofiltration membrane is shown in Table 2. The permeation flux of each solvent is arranged in the following order: acetone>ethyl acetate>methanol>ethanol>DMF>n-hexane. Among them, acetone has the highest flux of 15.6L m –2 h –1 bar –1 , the flux of n-hexane is the lowest at 1.9Lm –2 h –1 bar –1 . The solvent-resistant composite nanofiltration membrane has a rejection rate of 98.6% for Janus Green in ethanol solution, 97.8% for Erythrosin EB, 92.9% for Patent Blue VF, and 92.9% for Methyl Orange. The rate is 53.6%.

[0050] Table 2 Swellability of solvent-resistant nanofiltration membranes before and after solvent immersion

[0051...

Embodiment 3

[0053] In step (5) of Example 1, the mass concentration of GO-[VBzImIBa][Br] was changed from 1.0wt% to 2.0wt%, and other conditions remained unchanged. A composite structure solvent-resistant nanofiltration membrane with a thickness of 131 μm was obtained. Using the performance test method described in Example 1, the solvent resistance of the nanofiltration membrane is shown in Table 3. The permeation flux of each solvent is arranged in the following order: acetone>ethyl acetate>methanol>ethanol>DMF>n-hexane. Among them, acetone has the highest flux of 16.5L m –2 h –1 bar –1 , the flux of n-hexane is the lowest at 2.1Lm –2 h –1 bar –1 . The solvent-resistant composite nanofiltration membrane has a rejection rate of 98.8% for Janus Green in ethanol solution, 97.4% for Erythrosin EB, 92.4% for Patent Blue VF, and 92.4% for Methyl Orange. The rate is 53.3%.

[0054] Table 3 Swellability of solvent-resistant nanofiltration membranes before and after solvent immersion

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com