Silicon aerosol coating for outer wall and preparation method and application thereof

An aerosol and exterior wall technology, applied in the field of exterior wall paint, can solve the problems of poor suspension stability, poor thixotropy, poor weather resistance, etc., and achieve the effect of low cost, long service life and elegant color tone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

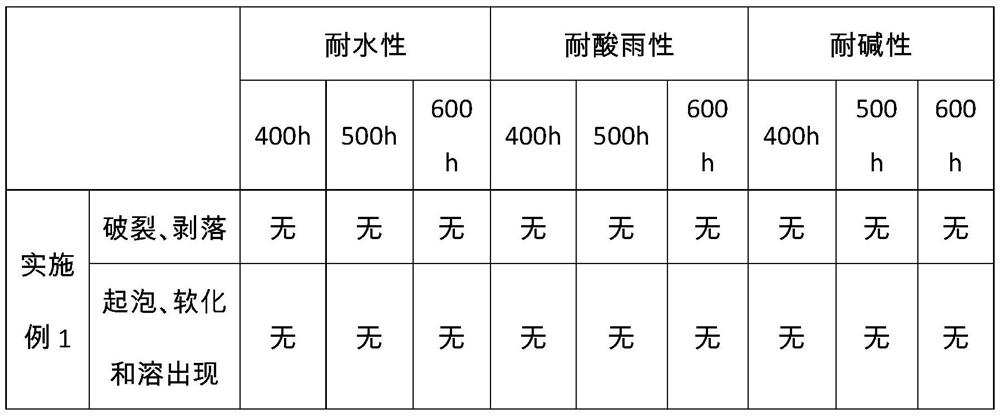

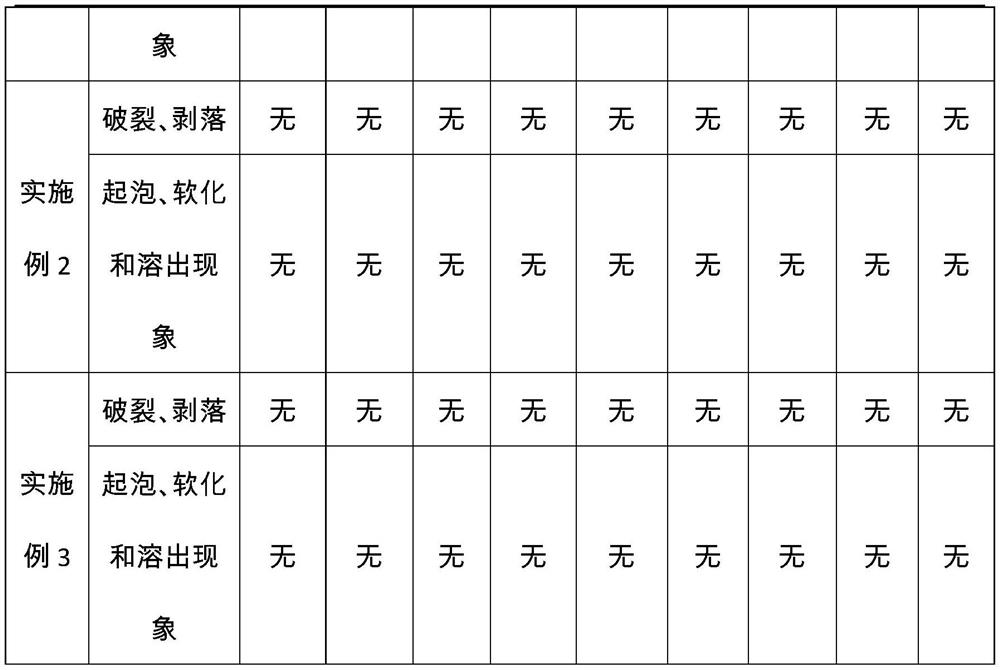

Embodiment 1

[0030] A kind of silicon aerosol paint for external wall, described silicon aerosol paint for external wall is made up of primer and varnish, the raw material ratio of described primer is: 100 parts of acrylate, 0.5 part of pigment , 2 parts of wetting and dispersing agent, 2 parts of defoamer, 0.01 part of fungicide, 2 parts of short oil alkyd resin, 2.5 parts of acetic acid, 2 parts of cellulose acetate butyrate, 1 part of triethanolamine, silica aerosol 5 parts, 5 parts of lithopone, 7 parts of talcum powder, 3 parts of ethylene glycol, 10 parts of heavy calcium carbonate, 5 parts of butyl acetate, 1 part of highly elastic water-soluble polyurethane, 0.1 part of ammonia water; the varnish The ratio of raw materials in parts by mass is: 100 parts of water, 0.5 parts of sodium benzoate, 5 parts of polyvinyl butyral, 0.1 part of hydroxyethyl cellulose, 2 parts of titanate coupling agent, 2 parts of fumed silica 3 parts, 3 parts of sodium carbonate, 9 parts of chlorinated paraf...

Embodiment 2

[0043] A kind of silicon aerosol paint for external wall, described silicon aerosol paint for external wall is made up of primer and varnish, the raw material ratio of described primer is: 100 parts of acrylate, 1.5 parts of pigment , 3 parts of wetting and dispersing agent, 3 parts of defoaming agent, 0.05 part of fungicide, 5 parts of triethanolamine, 15 parts of silica airgel, 8 parts of titanium dioxide, 11 parts of talcum powder, 5 parts of ethylene glycol, 20 parts of heavy calcium carbonate, 7 parts of butyl acetate, 3 parts of highly elastic water-soluble polyurethane, and 1 part of ammonia; 7 parts of vinyl butyral, 0.3 parts of hydroxyethyl cellulose, 3 parts of titanate coupling agent, 3 parts of fumed silica, 3 parts of styrene, 5 parts of sodium carbonate, 10 parts of calcium tripolyphosphate;

[0044] The preparation method of silicon aerosol paint for exterior wall comprises the steps:

[0045] The first step is to weigh the raw materials of the primer accordin...

Embodiment 3

[0056] A kind of silicon aerosol paint for external wall, described silicon aerosol paint for external wall is made up of primer and varnish, the raw material ratio of described primer is 100 parts of acrylate, 1 part of pigment, 2.5 parts of wetting and dispersing agent, 2.5 parts of defoamer, 0.03 part of fungicide, 2.5 parts of short oil alkyd resin, 3.5 parts of acetic acid, 3 parts of cellulose acetate butyrate, 3 parts of triethanolamine, 10 parts of silica aerosol part, 6 parts of lithopone, 9 parts of talcum powder, 4 parts of ethylene glycol, 15 parts of heavy calcium carbonate, 6 parts of butyl acetate, 2 parts of highly elastic water-soluble polyurethane, 0.5 part of ammonia water; The ratio of raw materials in parts by mass is: 100 parts of water, 1.5 parts of sodium benzoate, 6 parts of polyvinyl butyral, 0.2 parts of hydroxyethyl cellulose, 2.5 parts of titanate coupling agent, and 2.5 parts of fumed silica , 4 parts of sodium carbonate, 5 parts of calcium tripol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ductility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com