Tungsten oxide nanorod/titanium carbide quantum dot/indium sulfide nanosheet Z-type heterojunction composite material and preparation method and application thereof

A composite material and quantum dot technology, which is applied in the fields of inorganic nanocomposite materials and photocatalysis to achieve the effect of improving photocatalytic efficiency, increasing contact and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

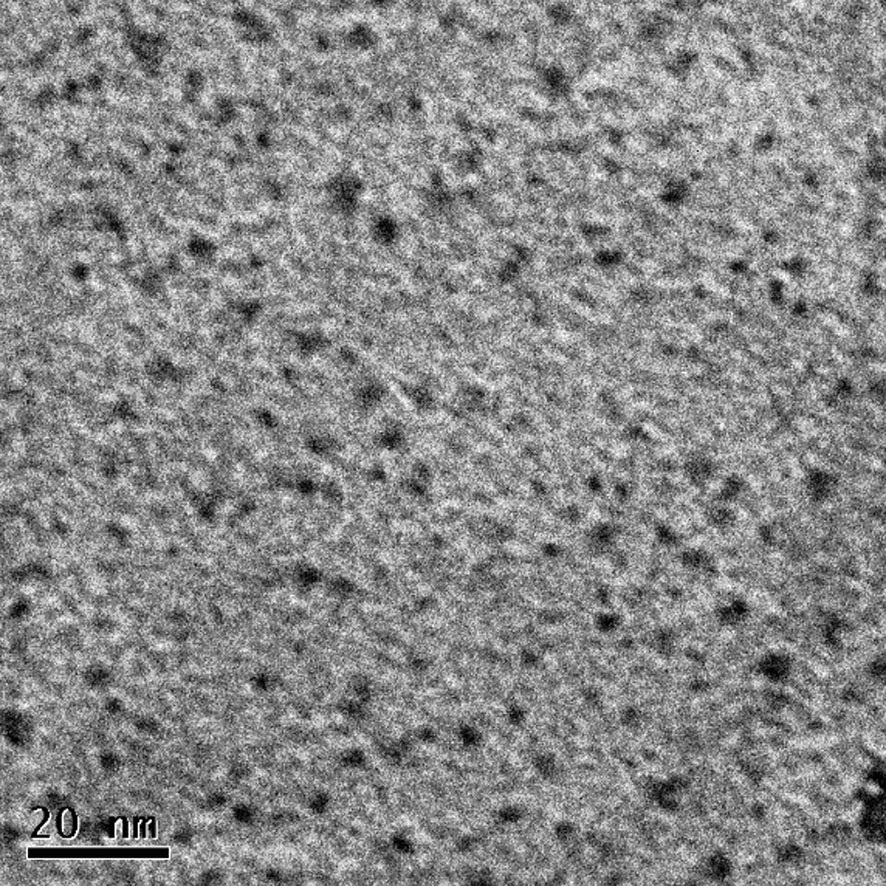

[0033] Example 1 Preparation of titanium carbide quantum dots

[0034] In a centrifuge tube, add 0.8 g of lithium fluoride to 10 mL of 9 mol / L hydrochloric acid and stir for 5 min, then add 0.45 g of titanium carbon aluminide; then stir at room temperature for 24 h for etching, and the reaction product is centrifuged and washed with water until the pH is 6 , re-add deionized water, shake it by hand for 10 minutes to obtain a layered titanium carbide solution; then bubble argon into the titanium carbide solution in the centrifuge tube for 5 minutes, and then freeze and thaw five times: first in a refrigerator at 4 °C Place it for 3 hours, then put it in a -40 °C refrigerator for 3 hours, and then place it at room temperature to thaw, complete one freeze-thaw, and repeat this process four times; Ultrasound at 150 W for 1 h to obtain a solution containing titanium carbide flakes and quantum dots; the solution was filtered three times through a 0.22 μm microporous membrane to filt...

Embodiment 2

[0036] Embodiment 2 The preparation of tungsten trioxide nanorods, the specific steps are as follows:

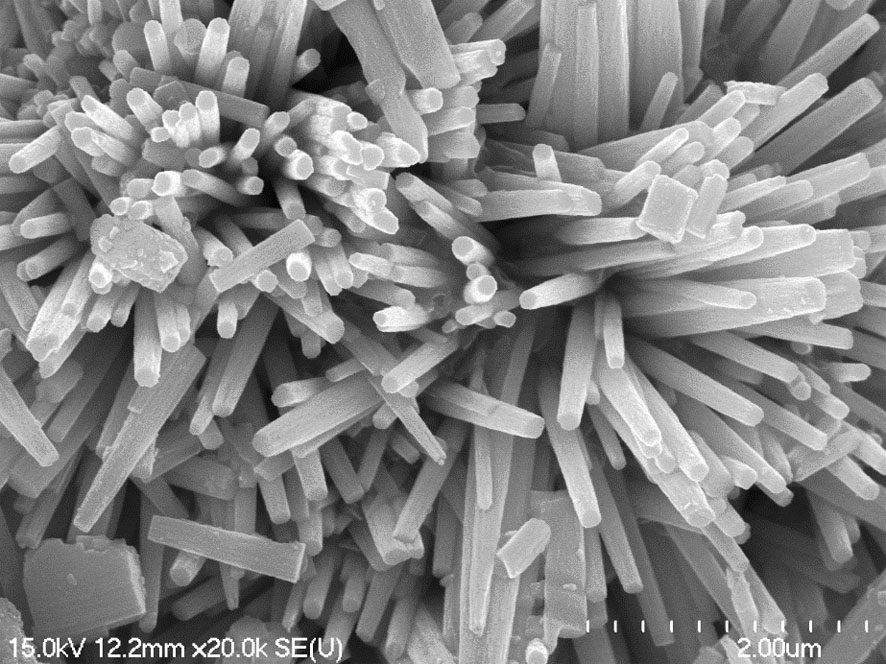

[0037] Add 0.825 g sodium tungstate dihydrate and 0.4 g sodium chloride into 20 mL deionized water, stir for 30 min, then add 3 mol / L hydrochloric acid solution to the above solution dropwise, and use a pH meter during the dropwise addition Test to make the solution pH=2; stir for another 3 hours; then transfer the solution to the reactor for hydrothermal reaction; After centrifugation and washing, they were placed in a drying oven at 65 °C and dried overnight to obtain tungsten trioxide nanorod powder.

[0038] attached figure 2 It is the scanning electron microscope picture of tungsten trioxide obtained above, and it can be clearly seen from the above picture that tungsten trioxide has a nanorod structure and is uniformly dispersed.

Embodiment 3

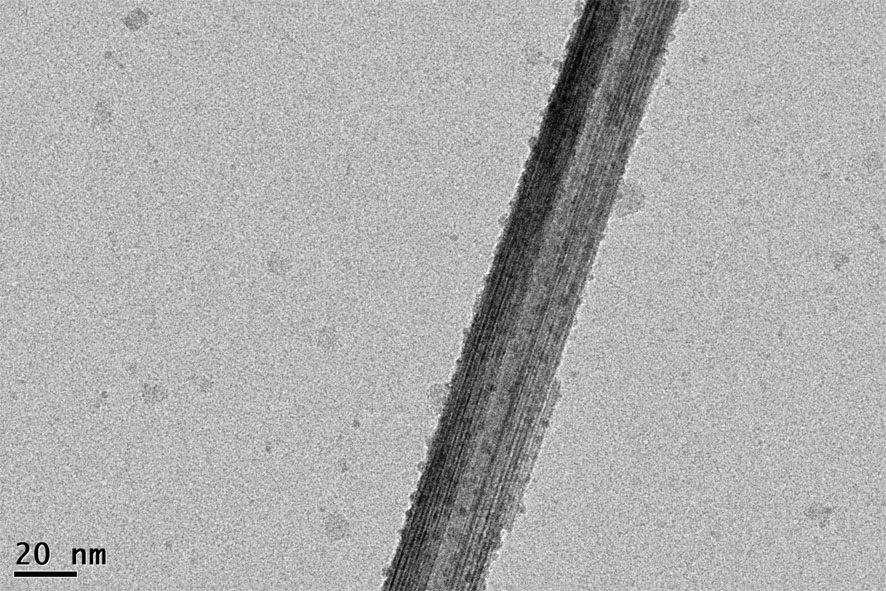

[0039] Example 3 Preparation of tungsten oxide nanorod / titanium carbide quantum dot / indium sulfide nanosheet Z-type heterojunction composite material, the specific steps are as follows:

[0040] Take 0.1 g of tungsten trioxide nanorod powder in Example 2 and add it to 120 mL of titanium carbide quantum dot aqueous solution, stir (1000 rpm) in a vacuum environment for 12 h, then let it stand at room temperature for 12 h, and then freeze-dry it The tungsten trioxide nanorod powder loaded with quantum dots was obtained by freeze-drying in a machine. Disperse 57.95 mg (1 mmol) of tungsten trioxide powder loaded with quantum dots into 10 mL of ethylene glycol, and dissolve 205 mg (2.8 mmol) of indium trichloride tetrahydrate in 15 mL of ethylene glycol; Mix in the flask, and then add 79 mg (4.2 mmol) of thioacetamide; then connect the flask to a spherical condenser and a three-way valve, and seal the joint, first use a vacuum pump to remove the air in the flask and condenser, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com