3D printed magnetic biological ceramic scaffold and preparation method thereof

A bioceramic and 3D printing technology, applied in the direction of additive processing, can solve the problems of lack of magnetism and controllable pore structure, lack of osteogenesis ability and therapeutic function, etc., achieve good biocompatibility and magnetic properties, improve Cracking problem, the effect of reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

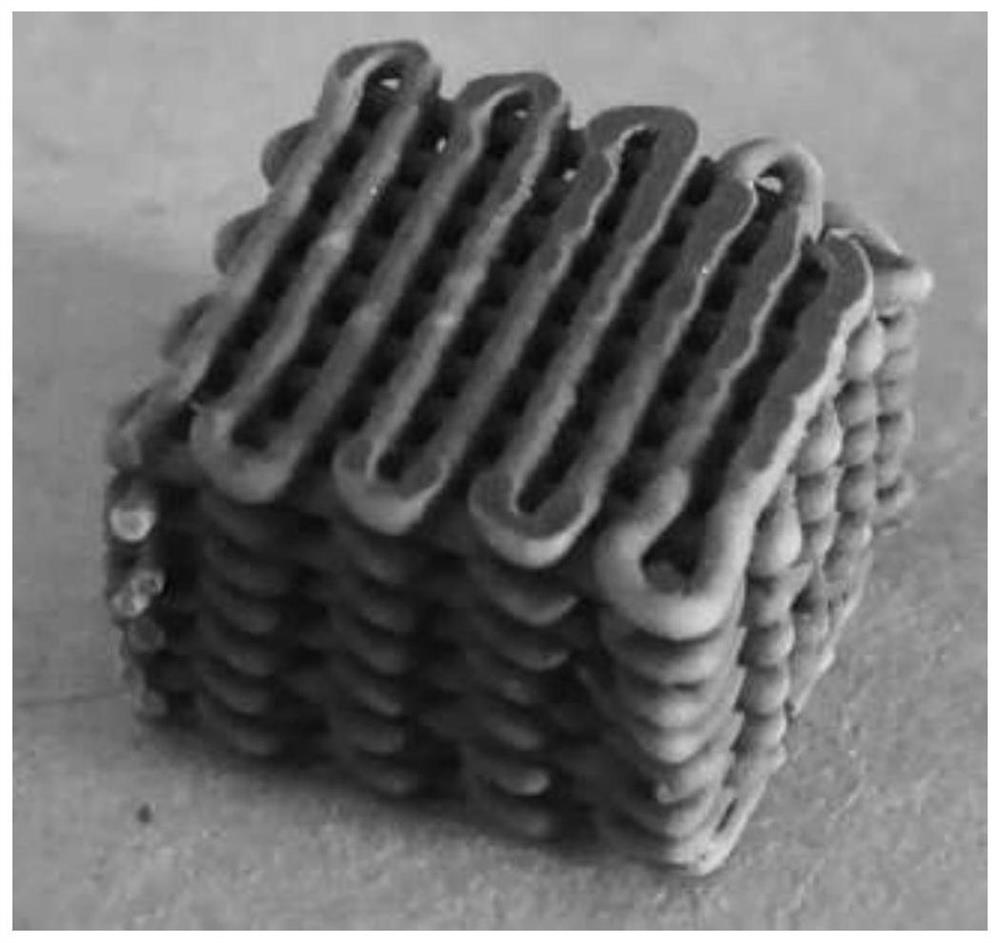

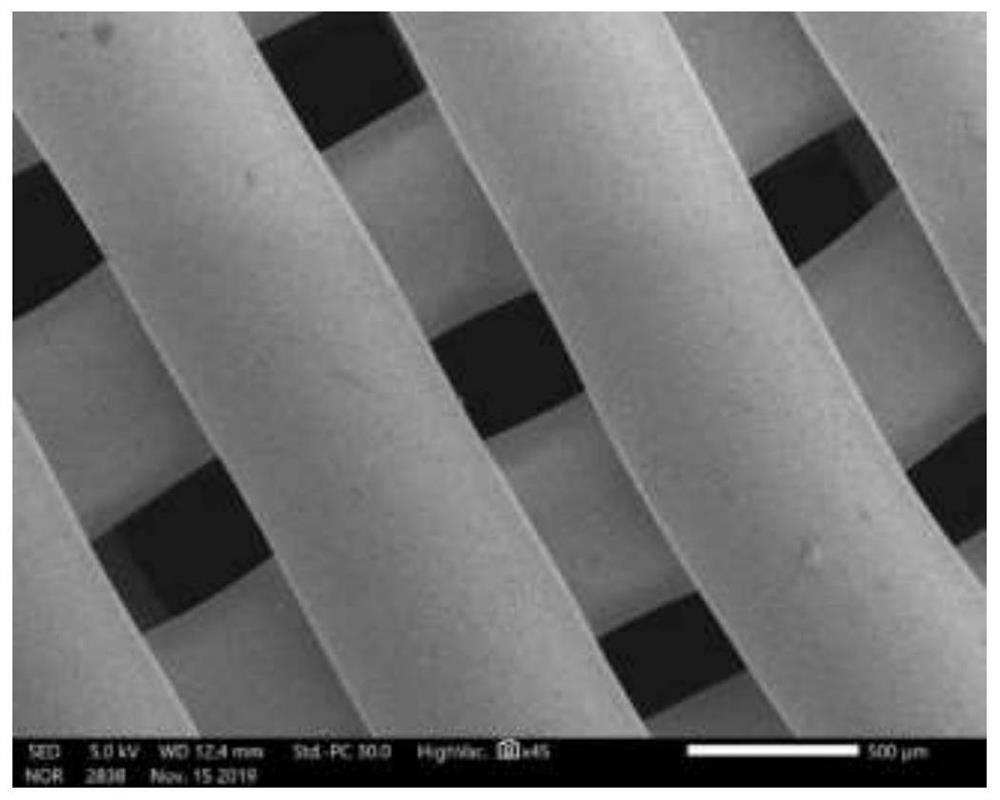

[0030] A 3D printing magnetic bioceramic support, its preparation method comprises the following steps:

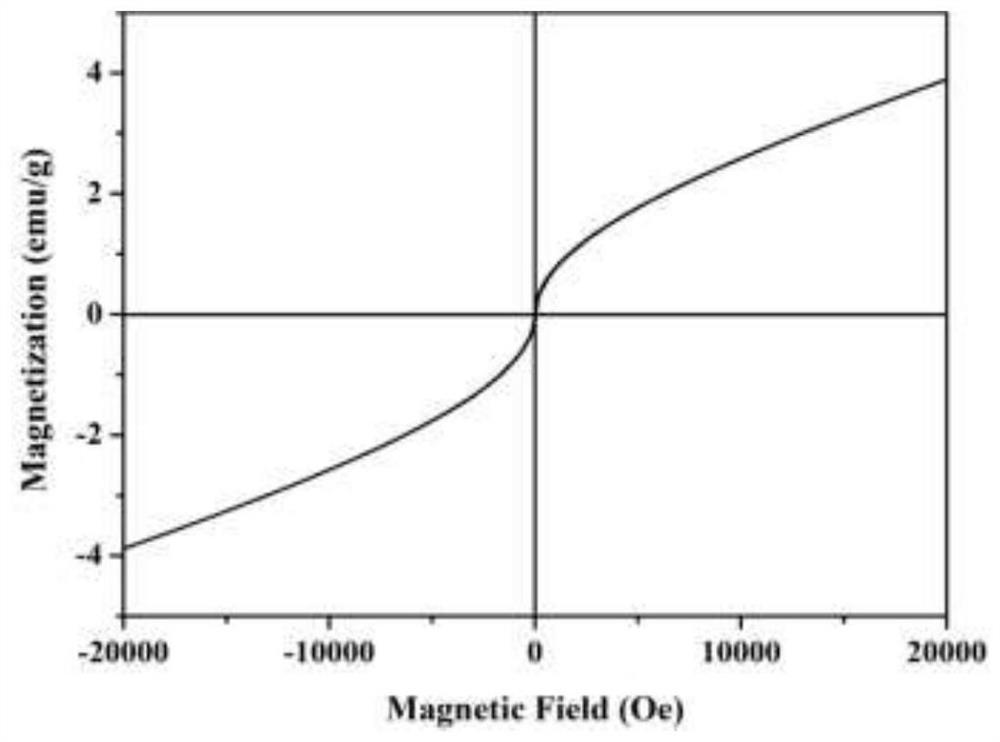

[0031] 1) Mix 60g of β-tricalcium phosphate (β-TCP) powder, 6g of iron tetroxide (Fe 3 o 4 ) magnetic nanopowder, concentration is 36g sodium alginate gel (20wt%) and concentration is 8g pluronic gel (10wt%), mix, and add in the high-energy planetary ball mill, ball mill 6h, be suitable for free extrusion Formed printing ink;

[0032] 2) Using 3D printing technology, put the obtained printing ink into the printing cylinder, select the three-dimensional support model, start the printing process to extrude the ink layer by layer to form the magnetic support blank; then soak and dry in the liquid desiccant diethylene glycol for 24 hours;

[0033] 3) Place the dried body in a degreasing furnace at a rate of 1°C / min to 500°C / min and keep it warm for 10 hours, cool to room temperature, then place it in a tube furnace, and heat it at a temperature of 5°C under a flowing nitroge...

Embodiment 2

[0037] A 3D printing magnetic bioceramic support, its preparation method comprises the following steps:

[0038] 1) Mix 60g of calcium silicate (CS) powder, 6g of ferric oxide (Fe 3 o 4 ) magnetic nanopowder, 28g sodium alginate gel (20wt%) and 16g pluronic gel (10wt%), mixed, and added in a high-energy planetary ball mill, ball milled for 6h, to obtain a printing ink suitable for free extrusion ;

[0039] 2) Using 3D printing technology, put the obtained printing ink into the printing cylinder, select the three-dimensional support model, start the printing process to extrude the ink layer by layer to form a magnetic support blank; then soak and dry in triethylene glycol for 24 hours;

[0040] 3) Put the dried green body in the degreasing furnace and raise the temperature at a rate of 1°C / min to 400°C / min for 20 hours in a tube furnace, cool to room temperature, and then place it in a tube furnace, in a flowing nitrogen atmosphere The temperature was raised to 1150°C / min at...

Embodiment 3

[0042] A 3D printing magnetic bioceramic support, its preparation method comprises the following steps:

[0043] 1) Mix 60g of β-tricalcium phosphate (β-TCP) powder, 6g of manganese zinc ferrite (Mn x Zn 1-x Fe 2 o 4 ) magnetic nanopowder, 30g xanthan gum (20wt%) and 14g pluronic gel (10wt%), mixed, and added in a high-energy planetary ball mill, ball milled for 6h, to obtain a printing ink suitable for free extrusion molding;

[0044] 2) Using 3D printing technology, put the obtained printing ink into the printing cylinder, select the three-dimensional support model, start the printing process to extrude the ink layer by layer to form the magnetic support body; then place it in diethylene glycol dimethyl ether to dry for 48 hours;

[0045] 3) Place the dried green body in a degreasing furnace at a rate of 2°C / min to 450°C / min and keep warm for 15 hours in a tube furnace, cool to room temperature, and then place it in a tube furnace, in a flowing nitrogen atmosphere The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com