Nano-copper powder and application thereof to preparation of antibacterial and mildew-proof carpet

A technology of nano-copper powder and nano-copper, which is applied in the direction of nanotechnology, nanotechnology, chemicals for biological control, etc., can solve problems such as the impact on human health, achieve good industrial prospects, simple preparation methods, and good dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Take 17.05g of copper chloride dihydrate and 0.1g of gum arabic and add them to 50ml of deionized water to obtain a uniformly mixed copper chloride aqueous solution.

[0028] Step 2: Add ammonia water dropwise to adjust the pH value of the above solution to about 9.0, and then add the mixed solution into an airtight container.

[0029] Step 3: Take 10ml of hydrogen-rich water and add it to the above solution, then raise the temperature to 95°C, and reflux for 4 hours under the action of ultrasound (ultrasonic power is 100W, ultrasonic frequency is 40kH). place.

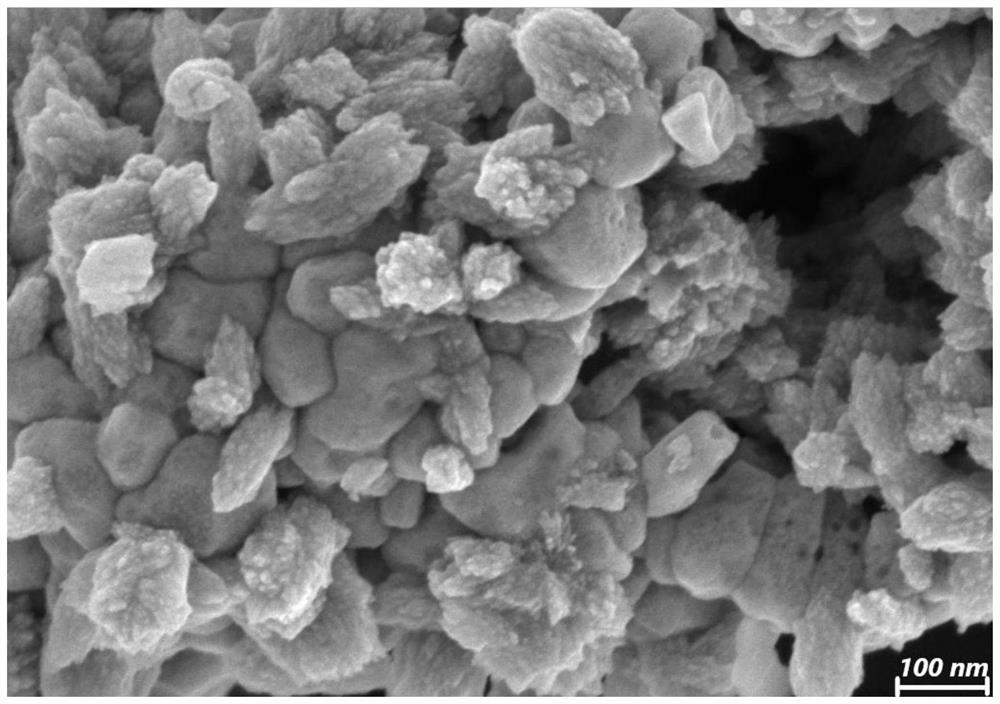

[0030] Step 4: After standing still, the reaction solution is centrifuged through a high-speed centrifuge (10,000 rpm) and washed 3 times with deionized water, and then the nano-copper slurry is dried by a freeze dryer (-80°C) for 12 hours to obtain nano-copper powder , its SEM image is shown in figure 1 shown.

[0031] Step 5: Take 10g of nano-copper powder and 40g of PET slices, melt, mix and extru...

Embodiment 2

[0035] Step 1: Take 8.50g of copper chloride dihydrate and 0.08g of sodium lignosulfonate and add them into 40ml of deionized water to obtain a uniformly mixed aqueous solution of copper chloride.

[0036] Step 2: Add ammonium bicarbonate solution dropwise to adjust the pH value of the above solution to about 9.5, and then add the mixed solution into a closed container.

[0037] Step 3: Take 0.5g vitamin C and add it to the above solution, then raise the temperature to 80°C, under the action of ultrasound (ultrasonic power 100W, ultrasonic frequency 40kH) reflux reaction for 6 hours, cool to room temperature after the reaction place.

[0038] Step 4: After standing still, the reaction solution is centrifuged through a high-speed centrifuge (8000 rpm) and washed 3 times with deionized water, and then the nano-copper slurry is dried by a freeze dryer (-60°C) for 12 hours to obtain nano-copper powder .

[0039] Step 5: Take 10g of nano-copper powder and 40g of PET slices, melt,...

Embodiment 3

[0043] Step 1: Take 30g of copper chloride dihydrate and 0.3g of sodium polymethacrylate and add them into 100ml of deionized water to obtain a uniformly mixed aqueous solution of copper chloride.

[0044] Step 2: Add ammonia solution dropwise to adjust the pH value of the above solution to about 10.0, and then add the mixed solution into an airtight container.

[0045] Step 3: Take 5.0g of glutathione and add it to the above solution, then increase the temperature to 70°C, reflux for 8 hours under the action of ultrasound (ultrasonic power is 100W, ultrasonic frequency is 40kH), and cool to Let stand at room temperature.

[0046] Step 4: After standing still, the reaction solution is centrifuged through a high-speed centrifuge (9000rpm) and washed 3 times with deionized water, and then the nano-copper slurry is dried by a freeze dryer (-70°C) for 18 hours to obtain nano-copper powder .

[0047] Step 5: Take 10g of nano-copper powder and 40g of PET slices, melt, mix and extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com