Negative electrode material and preparation method thereof, electrode and secondary battery

A negative electrode material and secondary battery technology, applied in secondary batteries, negative electrodes, battery electrodes, etc., can solve problems such as consumption, poor rate performance, and electrolyte consumption, and achieve high lithium ion conductivity and high structural stability , the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] Weigh 2000g of silicon-oxygen compound particles with a median particle size of 8 μm and a silicon-oxygen atomic ratio of 1:1 and place them in a CVD furnace, and feed high-purity argon gas into the furnace at a gas velocity of 500ccm throughout the subsequent process. First raise the temperature of the system to 900°C at 5°C / min and keep it for 60min, then pass acetylene into the furnace at a gas velocity of 300ccm for 60min for carbon film coating, then keep it at 900°C for 1 hour and then cool down to room temperature to get Silicon oxide particles with a carbon film layer are ready for subsequent operations.

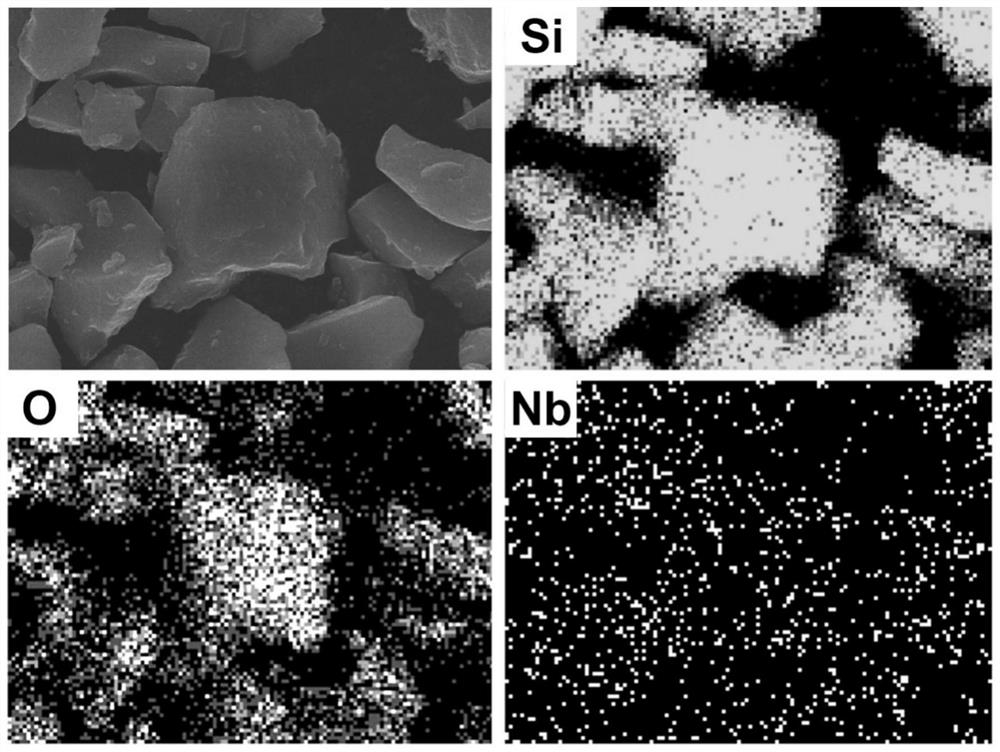

[0121] Weigh 500g of the above-mentioned silicon oxide compound particles with a carbon film layer, and uniformly disperse them in 1000ml of ethanol with a mass ratio of 30:1 through a high-speed dispersing disc with niobium oxide with a median particle size of about 1 μm. Subsequently, the resulting dispersion was continuously stirred at 150° C. until viscous...

Embodiment 2

[0129] The silicon oxide compound particles were coated with a carbon film by the same CVD process as in Example 1, and then passed through a 500-mesh sieve for later use. The silicon-oxygen compound particles with the carbon film layer obtained in the previous step and lithium hydride fine powder were uniformly mixed in a VC mixer for 30 minutes at a mass ratio of 10:1, and then transferred to a tube furnace, and heated under a high-purity argon atmosphere to Raise the temperature at 3°C / min to 750°C and keep for 6 hours. After natural cooling, pass through a 500-mesh sieve for subsequent operations.

[0130] Weigh 500g of the material obtained in the previous step, and uniformly disperse it in 1000ml of isopropanol through a high-speed dispersing disc at a mass ratio of 30:1 with niobium oxide with a median particle size of about 1 μm. Subsequently, the resulting dispersion was continuously stirred at 150° C. until viscous, then dried and coarsely crushed, and then passed th...

Embodiment 3

[0138] Weigh 2000g of silicon-oxygen compound particles with a median particle size of 7 μm and a silicon-oxygen atomic ratio of 1:1, and use a heating VC mixer to uniformly mix it with petroleum asphalt at a mass ratio of 15:1 to realize the production of petroleum asphalt. clad. The obtained product was transferred into a box furnace, and the temperature was raised to 1000°C at a rate of 5°C / min under a high-purity nitrogen atmosphere for 2h to realize in-situ carbonization of the asphalt-coated film layer on the surface of silicon oxide particles. After the treatment, the resulting material was crushed and passed through a 500-mesh sieve for subsequent operations.

[0139] Completely dissolve 0.13 mol ammonium niobium oxalate in a mixed solvent of 2000 mL of ethanol and water for later use, weigh 1000 g of silicon oxide particles with a carbon film layer obtained in the previous step and uniformly disperse them in the above ammonium niobium oxalate solution through a high-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com