Water-based environment-friendly primer-topcoat coating for superstructure and cabin of ship

A water-based, environmentally friendly technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of inability to cure and form a film, requiring high temperature baking at 80 °C, and low construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

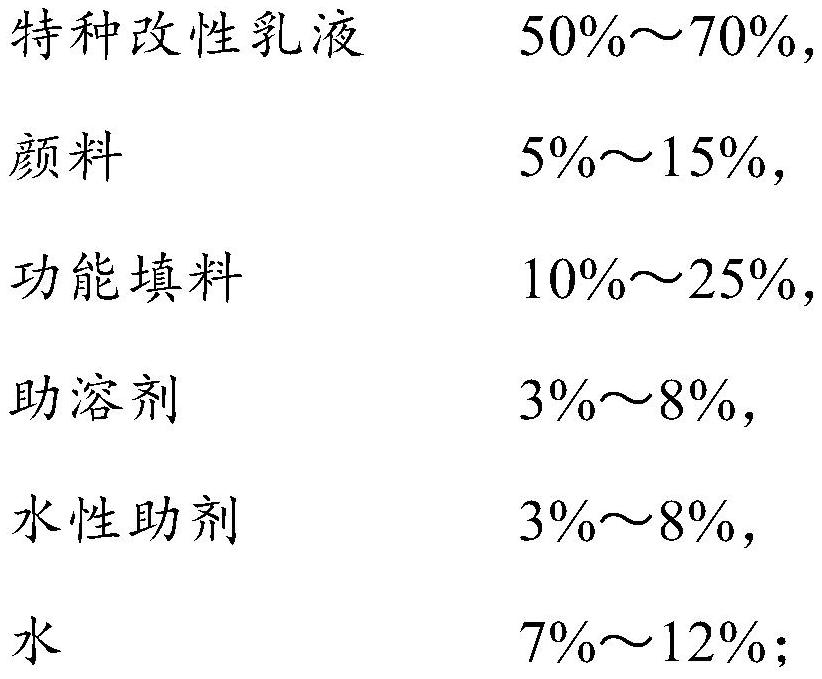

Method used

Image

Examples

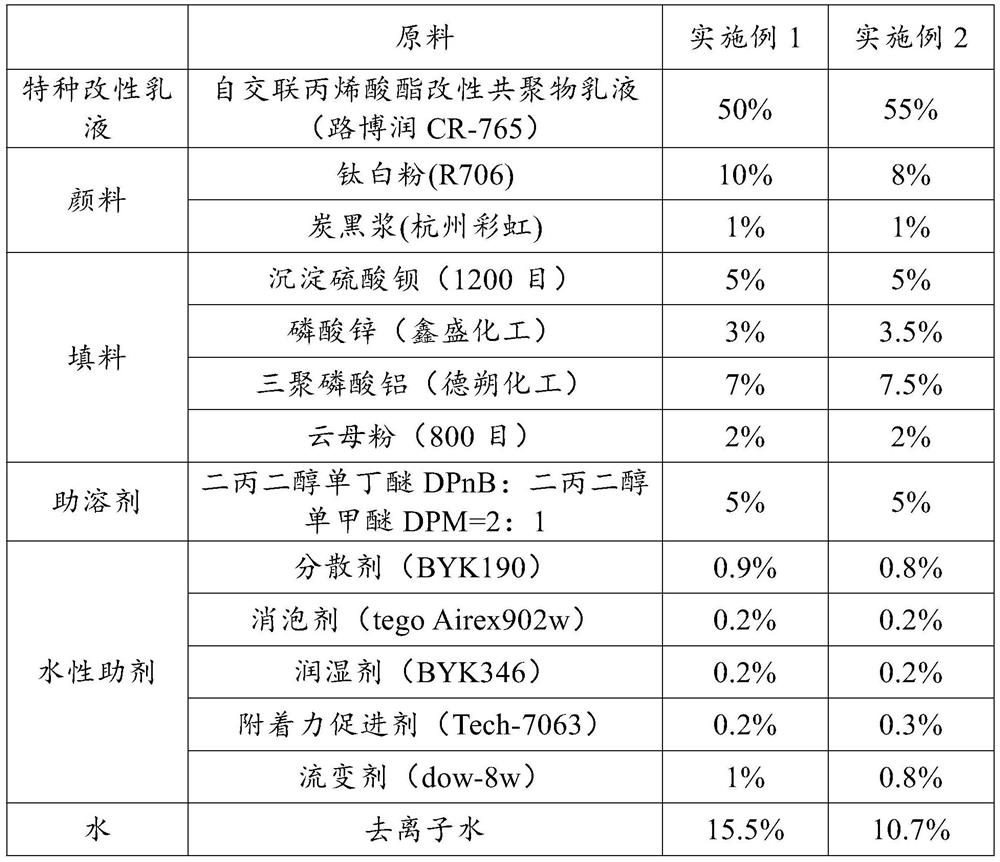

Embodiment 1-2

[0021] A kind of environment-friendly water-based bottom-surface-in-one coating for ship building and cabin of embodiment 1-2, wherein the typical formula includes the following components, see Table 1.

[0022] Table 1 The mass fraction of raw materials in Example 1-2

[0023]

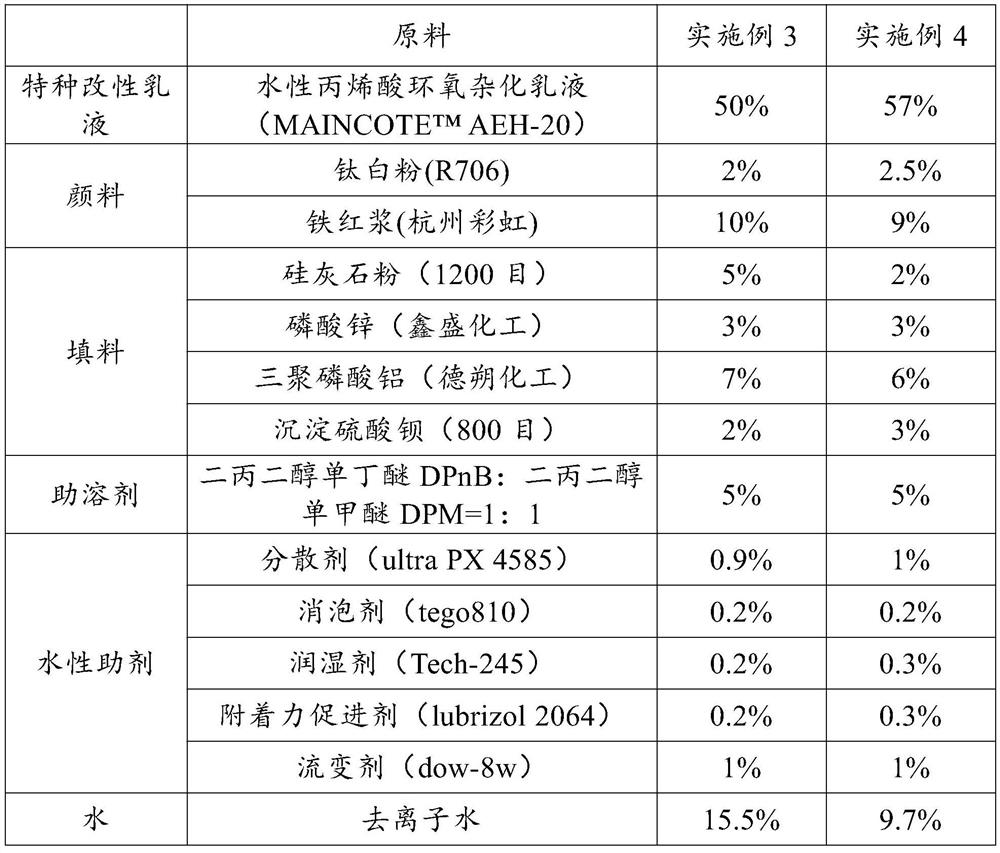

Embodiment 3-4

[0025] A kind of environment-friendly water-based bottom and surface all-in-one coating for ship superstructure and cabin of embodiment 3-4, wherein the typical formulation includes the following components, see Table 2.

[0026] The raw material mass fraction of table 2 embodiment 3-4

[0027]

Embodiment 5-6

[0029] A kind of environment-friendly water-based bottom-surface-in-one coating for ship building and cabin of embodiment 5-6, wherein the typical formula includes the following components, see Table 3.

[0030] The raw material mass fraction of table 3 embodiment 5-6

[0031]

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com