Cellulosic ethanol industrialized production system and method for co-production of fulvic acid

A technology of cellulosic ethanol and production system, which is applied in the fields of biofuel, application, organic fertilizer, etc. It can solve the problems of heavy pollution load of waste mash, incomplete purification of cellulose, and difficult processing, etc., so as to ensure sustainable circulation Effects of operation, reduction of sewage generation, and increase of ethanol concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0226] The first step, pretreatment and material preparation: use wheat straw as raw material, adopt the alkaline imonium method to pulp and carry out cooking pretreatment to obtain slurry.

[0227] 5 kg was sampled, and the solid content was 23%, and the fiber components were 60% cellulose, 33.6% hemicellulose, and 6.4% lignin and ash.

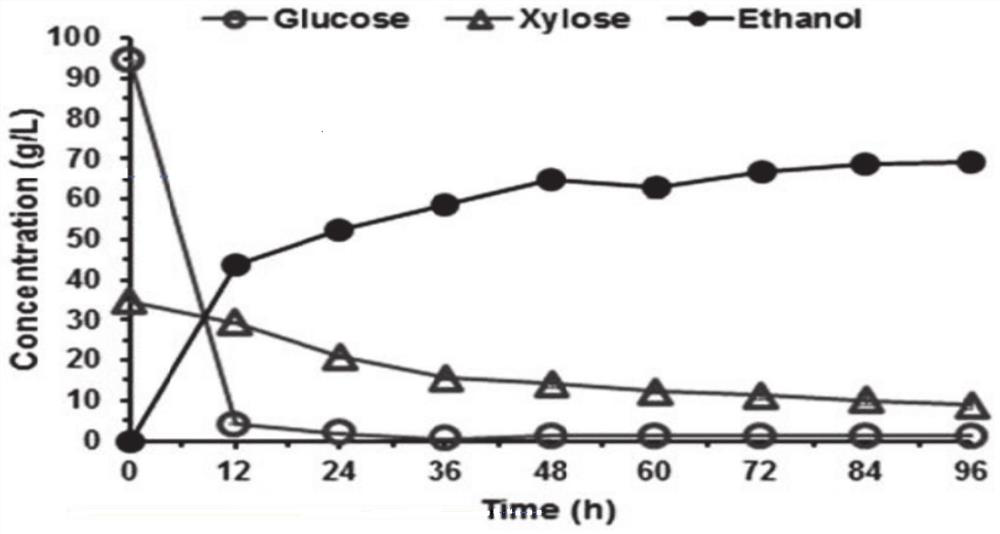

[0228] The second step, enzymatic saccharification: Cellulase is Novozymes CTec2.0, the dosage is 8 mg enzyme protein / g dry basis material, 50 ℃, enzymatic saccharification for 36 hours to obtain 94.5 g / L glucose and 34.6 g / L wood sugar.

[0229] The third step, fermentation: fermented with original raw materials, without any dilution and drying. The fermentation method is simultaneous saccharification and glucose / xylose co-fermentation. 20% solid content, 5L fermenter, 30°C, 10% inoculum, the fermentation strain is Saccharomyces cerevisiae engineering bacteria.

[0230] Fermentation time: 96 hours, data is checked every 12 hours.

[0231...

Embodiment 2

[0254] The first step: pre-processing materials. Wheat straw is used as a raw material, firstly pulping by neutral imonium method is used for cooking pretreatment to obtain slurry a; and then acidifying treatment is performed on slurry a to obtain slurry b. The acidification treatment process is: 2% hydrochloric acid, 8% pulp concentration, cooking temperature 95-100°C, time 90min, washing three times, pH7.

[0255] Sampling pulp b5 kg, recorded solid content 35%, recorded fiber components: 64% cellulose, 18% hemicellulose, lignin and ash 18%.

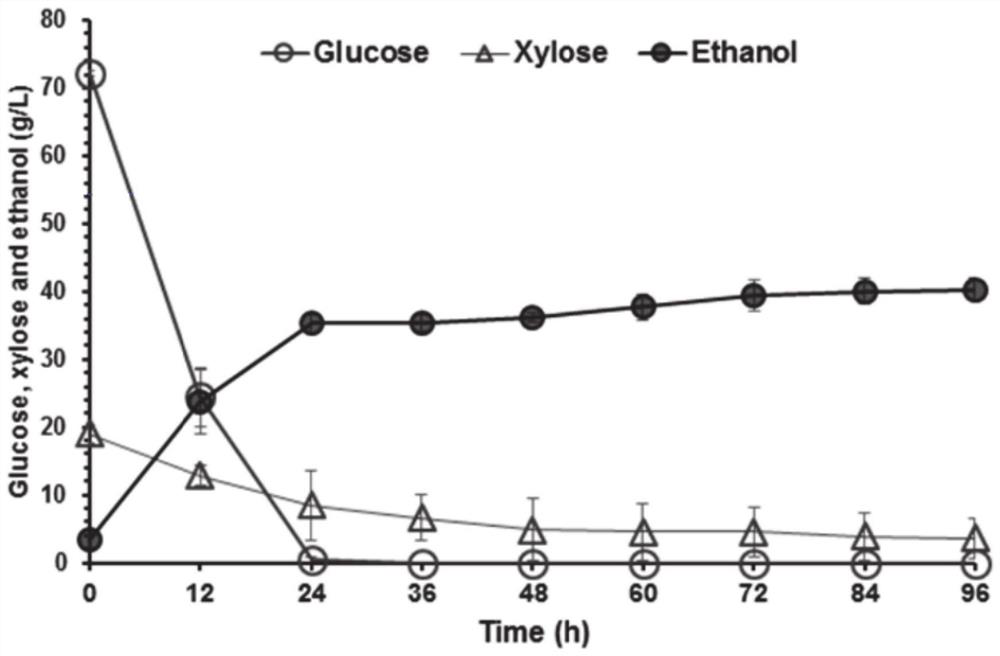

[0256] The second step, enzymatic hydrolysis and saccharification: cellulase is Novozymes CTec2.0, the dosage is 4mg enzyme protein / g dry basis material, 50℃, enzymatic hydrolysis and saccharification for 36 hours to obtain 72.2g / L glucose and 19.0g / L wood sugar.

[0257] The third step, fermentation: fermented with original raw materials, without any dilution and drying. The fermentation method is simultaneous saccharification and ...

Embodiment 4

[0294] Pretreatment cooking purification unit water balance

[0295] (1) Process, see Figure 5 :

[0296] (2) Water balance of each node:

[0297] ①Steaming, liquid ratio 1:3~4;

[0298] ②Washing, washing and separation to obtain ③Fulvic acid dilute black liquor 7-12 tons / ton of fulvic acid, solid content 8-12%;

[0299] 4. Evaporate and concentrate to obtain 2 tons of thick black liquor of fulvic acid with a solid content of 40-60%, and

[0300] ⑥Distilled water 5-10 tons / ton of fulvic acid;

[0301] ⑥Distilled water is reused for ①cooking and ②washing, and the excess part—⑦discharge up to standard;

[0302] ⑤ 2 tons of fulvic acid concentrated black liquor were sprayed and dried to obtain ⑧ 1 ton of fulvic acid dry powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com