Electrosurgical instrument based on smokeless electrode

An electrosurgical instrument and electrode technology, applied in the field of medical equipment, can solve the problems of wasting manpower, inducing mutation, and blocking the vision of the chief surgeon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] (2) The preparation of carbon nanotubes also adopts the preparation method of chemical vapor deposition, using 300nm thick silicon dioxide as the growth substrate, using Fe / MgO as the catalyst, the carbon source is acetylene and benzene, the growth temperature is 800 ° C, and the pressure is 1 atm , the growth time is 20-30min, and the thickness is 50nm.

[0040] (3) The preparation method of metal (Pt, Al, Au, Ag, Ni, Fe, Sn, Mn, W, Cu, Ti, Mo, Zn or a combination of several) nanowires is a hydrothermal method, Taking the preparation of copper nanowires as an example, 1.7g of copper chloride dihydrate, 4g of glucose, and 14g of hexadecylamine were dissolved in water, stirred for 12 hours, heated at 120°C for 6 hours, cooled and centrifuged, and dispersed in isopropyl Alcohol solution to obtain copper nanowires.

[0041] (4) The preparation method of silicon carbide, diamond, and titanium nitride is magnetron sputtering. Taking the preparation of silicon carbide as an ...

Embodiment 1

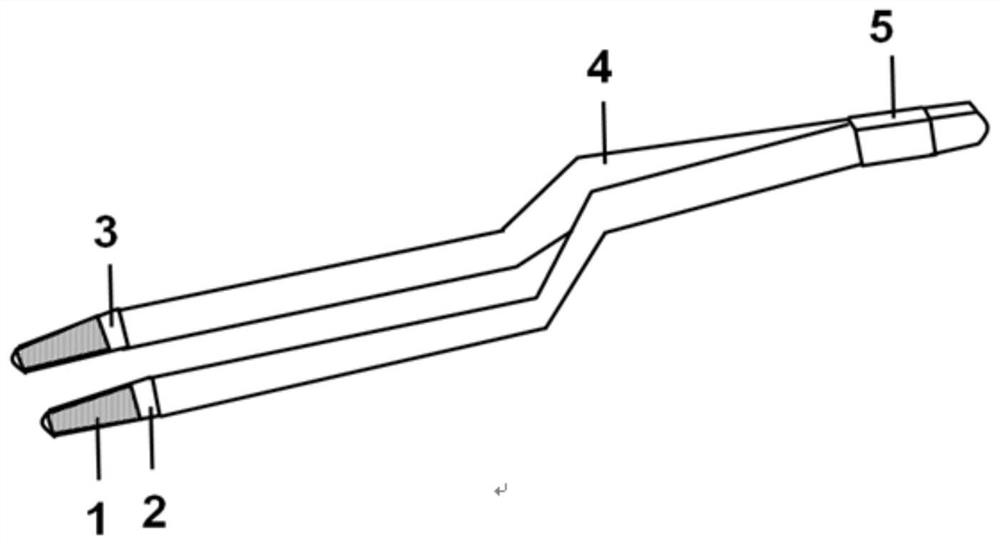

[0045] An electrosurgical instrument based on graphene-coated smokeless electrodes, such as figure 1 As shown, the high thermal conductivity, anti-sticking, and high temperature resistant graphene coating is covered on the outer surface of the electrode head of the entire electrosurgical instrument (high-frequency electric knife), as follows:

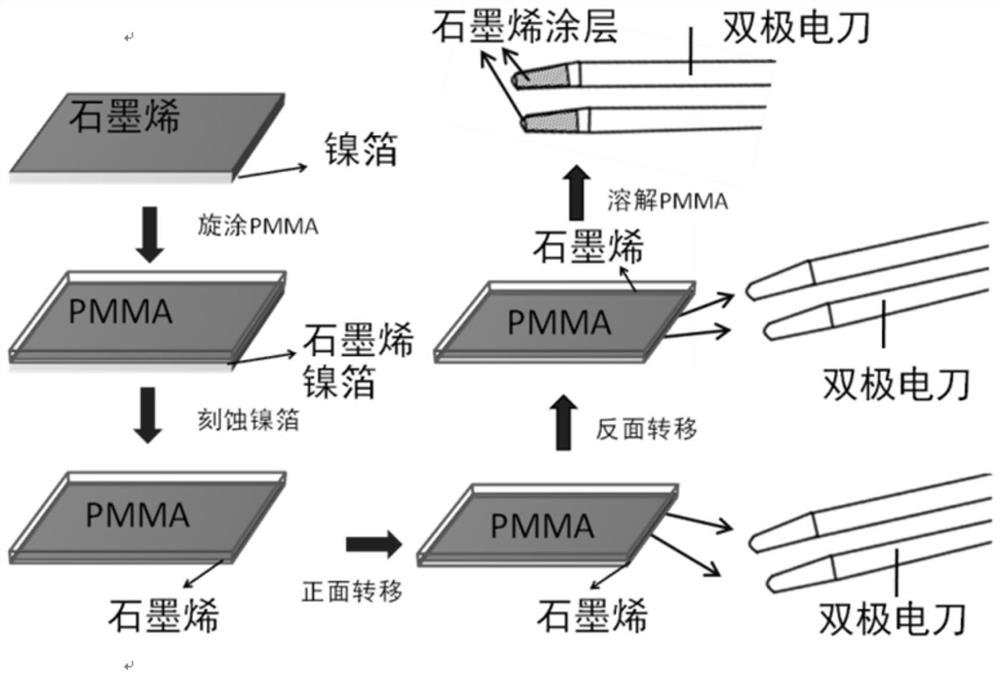

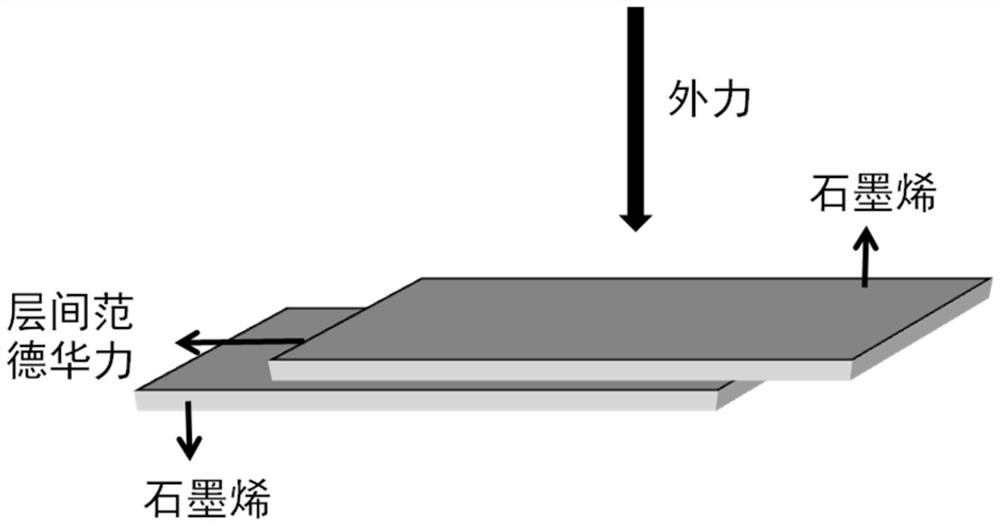

[0046] First, large-area, high-quality graphene with a thickness of 100 layers was grown by chemical vapor deposition. Then, the multi-layer graphene is transferred and covered on the upper and lower surfaces of the electrode blade by wet transfer, spin coating and other film transfer technologies. The schematic diagram of wet transfer is shown in the attached figure 2 shown. Among them, the size of graphene: the length and width are consistent with the size and shape of the electrode; the thickness of graphene is 70 nanometers (100 layers of graphene are coated on the upper and lower surfaces of the electrode), and the thickness of n...

Embodiment 2

[0050] For electrosurgical instruments based on carbon nanotube-coated smokeless electrodes, high thermal conductivity, anti-sticking, and high-temperature-resistant carbon nanotube coatings cover the entire outer surface of the electrode head of the electrosurgical instrument (high-frequency electric knife), as follows :

[0051] First, a 5 cm × 5 cm, 50 nm thick carbon nanotube film was grown by chemical vapor deposition, and the shape of the carbon nanotube film was cut with scissors to be consistent with the size and shape of the electrode tip. Then, the carbon nanotube film is transferred and covered on the upper and lower surfaces of the electrode blade by wet transfer technology.

[0052] The carbon nanotube coating has a thickness of 100 nanometers (a 50 nanometer thick carbon nanotube film is transferred on the upper and lower surfaces of the electrode), and the nanometer-sized thickness helps to strengthen the interaction between the coating and the substrate and red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com