Preparation method of high-performance flame-retardant fibers

A flame-retardant fiber and high-performance technology, which is applied in the direction of flame-retardant fiber, fiber type, fiber treatment, etc., can solve problems such as difficulty in ensuring sufficient and uniform components, inability to effectively modify porous fibers, and formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

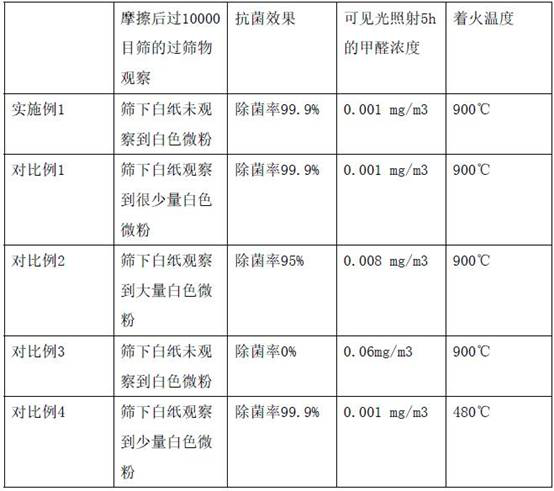

Examples

Embodiment 1

[0030] Including the following steps:

[0031] 1) Mix a certain amount of deionized water and absolute ethanol in a certain proportion to form a mixed solvent, wherein the volume ratio of deionized water and absolute ethanol is 1:9-15;

[0032] 2) Weigh an appropriate amount of polyacrylonitrile and dissolve it in the above mixed solvent, and stir vigorously at 50°C to form a sol;

[0033] 3) Electrospin the above sol through an electrospinning machine, adjust the spinning voltage of the electrospinning machine to 25-45 kV, so that the spinning solution is sprayed to form nanofibers with a diameter between 100-500nm, and the nanofibers are sprayed On the substrate, frozen solid nanofibers are formed on the substrate; the substrate is a circular copper sheet, and the receiving distance of the substrate is 10-20cm; the temperature of the substrate collected in the electrospinning machine is controlled from -50°C to -20°C ℃, so that the water in the sol system forms fine ice cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com