Simple and easy-to-operate aluminum alloy surface chemical nickel plating pretreatment process

An aluminum alloy surface, electroless nickel plating technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the complicated and cumbersome problems of secondary zinc immersion treatment, and achieve low cost, high efficiency, and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, the sample is a deformed 6061 aluminum alloy, and the specific steps are as follows:

[0034] 1) Degreasing: Use alcohol to degrease the surface of the sample, soak at 25°C for 5 minutes;

[0035] 2) Activation: The activation treatment solution is potassium phosphate 30g / L, sodium carbonate 25g / L, malic acid 1.5g / L, magnesium chloride 2g / L, ethylene bisstearamide (EBS) 1g / L, sodium nitrite ( NaNO 2 ) 2g / L, sodium dodecylbenzene sulfonate 2g / L aqueous solution, the pH value is 10, place the sample in the activation treatment solution, soak at 25°C for 3min;

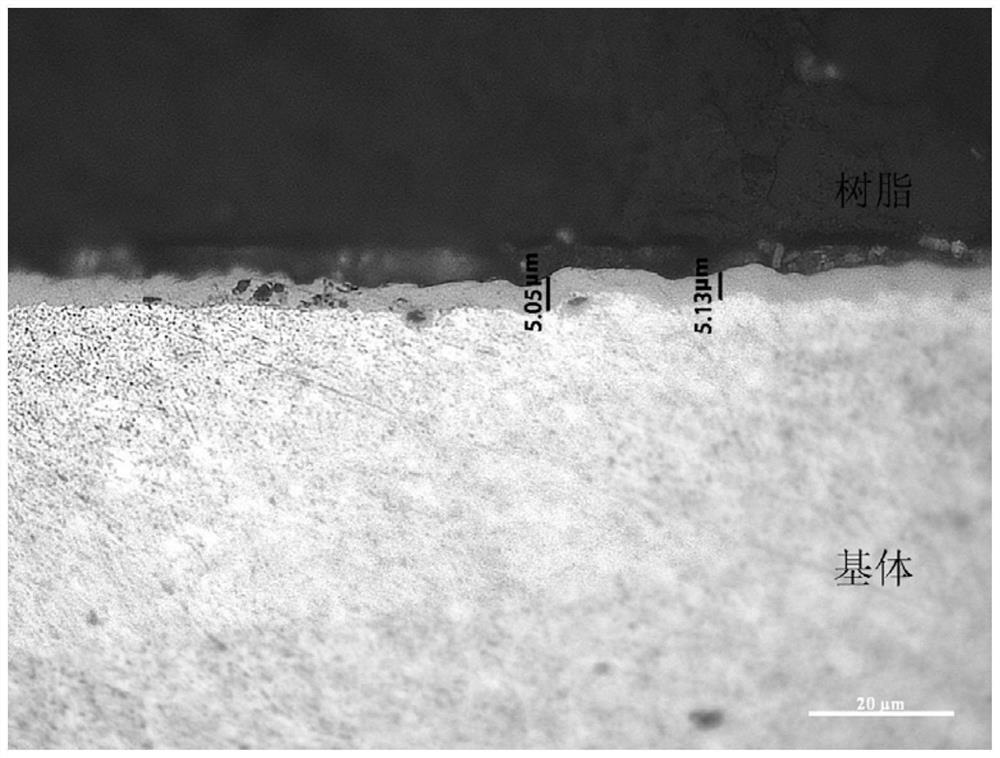

[0036]3) Electroless nickel plating: The electroless nickel plating solution is an aqueous solution of nickel sulfate 20g / L, sodium hypophosphite 20g / L, potassium acetate 30g / L, potassium citrate 10g / L, copper sulfate 40mg / L, and thiourea 4g / L , the pH value is 5.4, the sample is placed in the electroless nickel plating solution, soaked at 80°C for 1h. The nickel-phosphorus coating prepared b...

Embodiment 2

[0038] In this embodiment, the sample is a deformed 6061 aluminum alloy, and the specific steps are as follows:

[0039] 1) Degreasing: Use alcohol to degrease the surface of the sample, soak at 30°C for 10 minutes;

[0040] 2) Activation: The activation treatment solution is sodium phosphate 20g / L, potassium carbonate 25g / L, lactic acid 1g / L, magnesium oxide 1g / L, ethylene bisstearamide (EBS) 2g / L, sodium hexametaphosphate 2g / L, potassium silicate 5g / L, glycerin fatty acid 3g / L aqueous solution, pH value is 9.5, place the sample in the activation treatment solution, soak at 30°C for 4min;

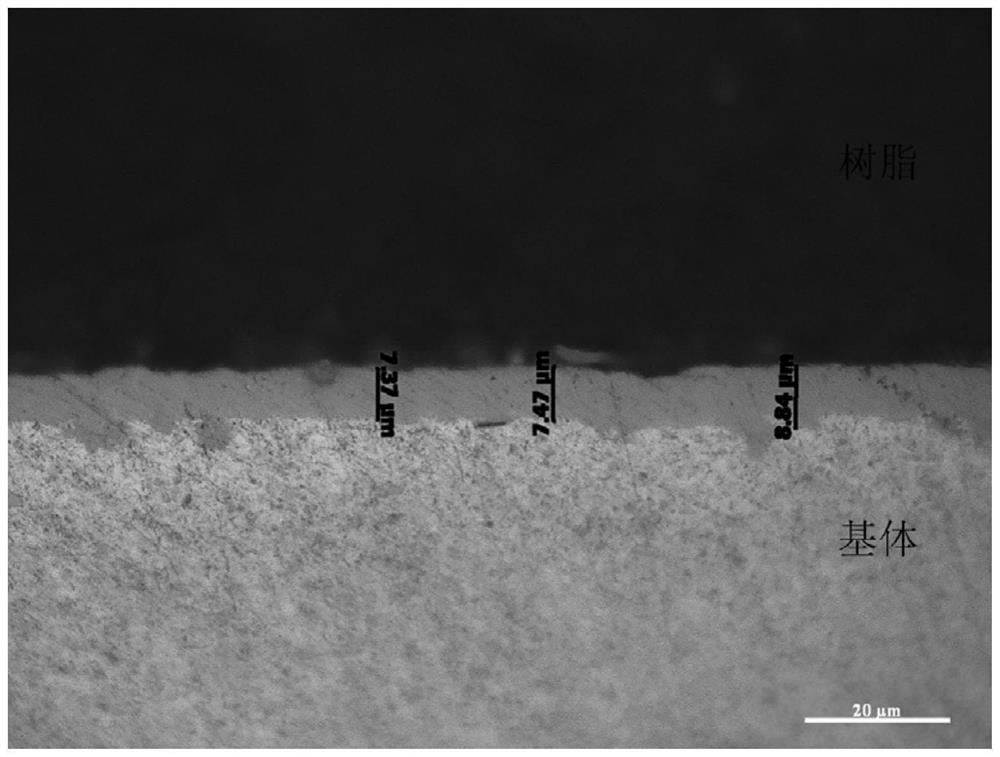

[0041] 3) Electroless nickel plating: The electroless nickel plating solution is nickel sulfate 30g / L, sodium hypophosphite 20g / L, sodium acetate 30g / L, sodium citrate 20g / L, sodium saccharin 40mg / L, 1,4 butynediol 10mg / L, thiourea 2g / L aqueous solution, the pH value is 5.6, place the sample in the electroless nickel plating solution, soak for 1h at 80°C. The nickel-phosphorous coating ...

Embodiment 3

[0043] In this embodiment, the sample is extruded 2024 aluminum alloy, and its specific steps are as follows:

[0044] 1) Degreasing: Use alcohol to degrease the surface of the sample, soak at 25°C for 8 minutes;

[0045] 2) Activation: The activation treatment liquid is sodium phosphate 15g / L, sodium carbonate 30g / L, salicylic acid 1g / / L, cadmium chloride 2g / L, monoglyceride stearate (GMS) 2g / L, silicic acid Sodium 1g / L, glycerin fatty acid 3g / L aqueous solution, pH value is 9, place the sample in the activation treatment solution, soak at 25°C for 5min;

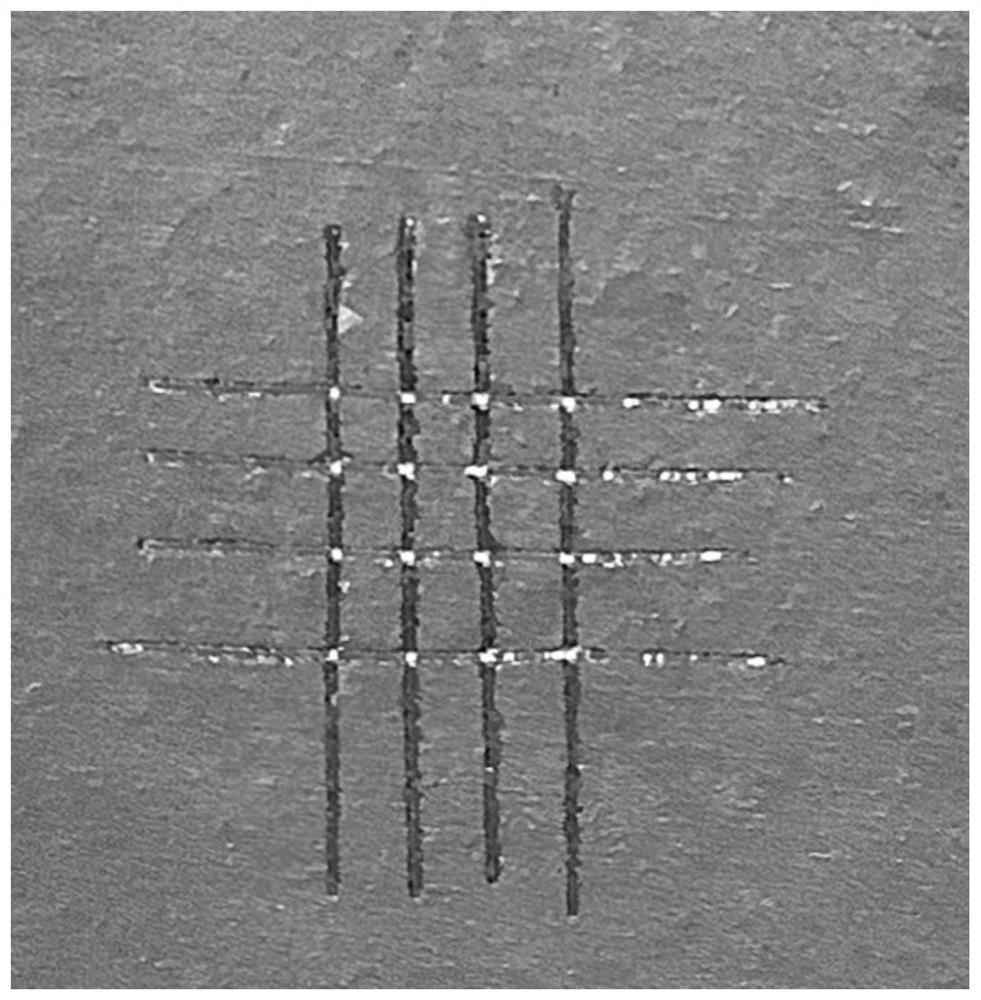

[0046] 3) Electroless nickel plating: The electroless nickel plating solution is basic nickel carbonate 10g / L, sodium hypophosphite 20g / L, sodium acetate 30g / L, potassium citrate 10g / L, copper sulfate 60mg / L, thiourea 3g / L Aqueous solution, pH value is 5.4, the sample is placed in the electroless nickel plating solution, soaked for 1.5h at 85°C. The nickel-phosphorus coating prepared by this method is silver-colored and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com