Preparation method of diosgenin chitosan carrier

A technology of diosgenin and transfer body, applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of low yield of diosgenin, cumbersome operation, and long consumption time, and achieve Shorten the separation time, optimize the preparation process, and have good anti-inflammatory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

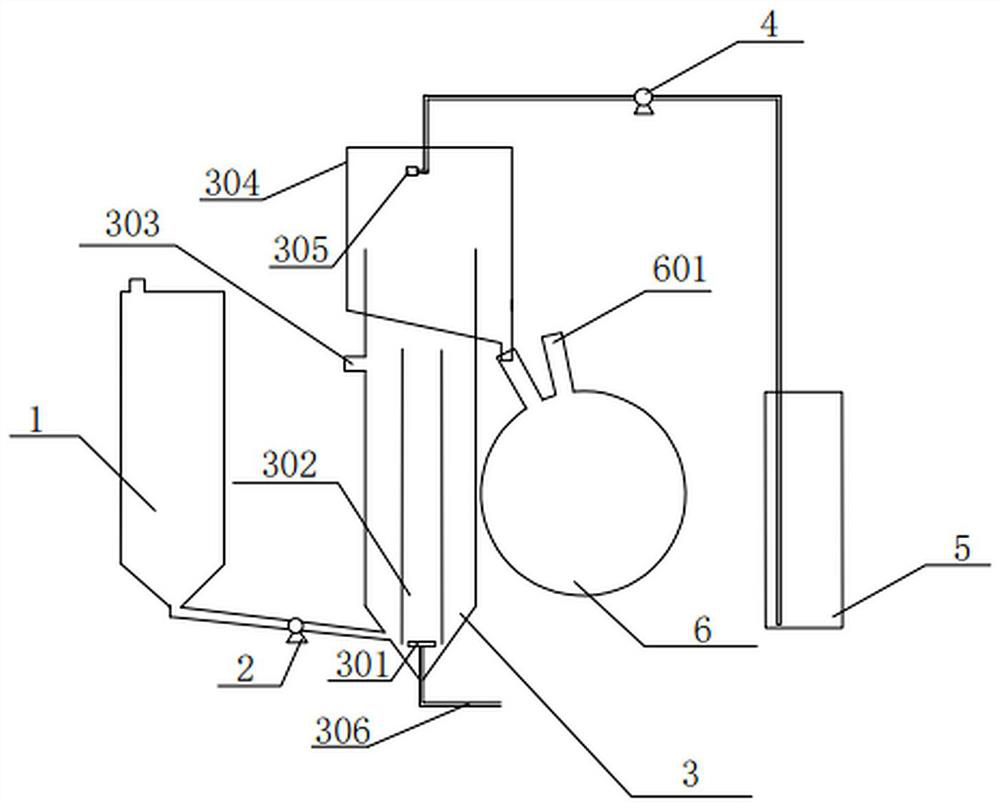

Image

Examples

Embodiment 1

[0026] A preparation method of diosgenin chitosan transfer body, which is extracted by the following steps:

[0027] S1. Crush 10 g of the rhizome of Dioscorea scutellariae and pass through an 80-mesh sieve, add 5 times the volume of deionized water to soak for 1 hour, adjust the pH to 6.5 with sodium acetate-acetic acid buffer, then add enzymes to enzymatically hydrolyze at 40°C for 45 minutes, then heat at 90°C After the enzyme is inactivated, adjust the pH to neutral, add 5 mL of sodium lauryl sulfate aqueous solution and 2 mL of magnesium chloride solution, soak for 3 hours, then undergo ultrasonic treatment at 24KHz for 30 minutes, then centrifuge at 4000r / min for 15 minutes, take the supernatant, filter, and obtain Ultrasonic extraction solution;

[0028] S2, add 0.2 times the volume of sulfuric acid solution into the ultrasonic extraction solution, stir and hydrolyze at 105°C for 2 hours, neutralize to neutral with saturated sodium carbonate solution after hydrolysis, o...

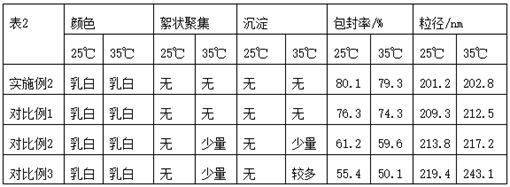

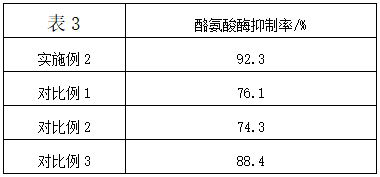

Embodiment 2

[0038] A preparation method of diosgenin chitosan transfer body, which is extracted by the following steps:

[0039] S1, crush 12 g of the rhizome of Dioscorea scutellariae through an 80-mesh sieve, add 5.5 times the volume of deionized water to soak for 1.5 hours, adjust the pH to 6.5 with sodium acetate-acetic acid buffer solution, then add enzymes to enzymolyze at 40°C for 50 minutes, 90 After the enzyme is inactivated at ℃, adjust the pH to neutral, add 7 mL of sodium lauryl sulfate aqueous solution and 2.5 mL of magnesium chloride solution, soak for 3.5 hours, and then undergo ultrasonic treatment at 25KHz for 35 minutes, then centrifuge at 4500r / min for 18 minutes, and take the supernatant. Filter to obtain ultrasonic extract;

[0040] S2, adding 0.2 times the volume of sulfuric acid solution into the ultrasonic extraction solution, stirred and hydrolyzed at 105°C for 2.5h, neutralized to neutral with saturated sodium carbonate solution after hydrolysis to obtain diosgen...

Embodiment 3

[0049] A preparation method of diosgenin chitosan transfer body, which is extracted by the following steps:

[0050] S1. Crush 15g of the rhizome of Dioscorea scutellariae through a 100-mesh sieve, add 6 times the volume of deionized water to soak for 2 hours, adjust the pH to 6.5 with sodium acetate-acetate buffer, then add enzymes to enzymatically hydrolyze at 40°C for 55min, then heat at 90°C After the enzyme is inactivated, adjust the pH to neutral, add 10 mL of sodium lauryl sulfate aqueous solution and 3 mL of magnesium chloride solution, soak for 4 hours, then undergo ultrasonic treatment at 26KHz for 40 minutes, then centrifuge at 5000r / min for 20 minutes, take the supernatant, filter, and obtain Ultrasonic extraction solution;

[0051] S2, add 0.2 times the volume of sulfuric acid solution into the ultrasonic extraction solution, stir and hydrolyze at 105°C for 3 hours, neutralize to neutral with saturated sodium carbonate solution after hydrolysis, obtain diosgenin h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com