Perovskite solution with controllable and adjustable operation time window, cell, preparation method and application

An operating time, perovskite technology, applied in applications, circuits, photovoltaic power generation, etc., can solve the problems of fast nucleation and crystallization rate, narrow processing time window, inability to apply perovskite film deposition, etc. The effect of high photoelectric conversion efficiency and novel preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

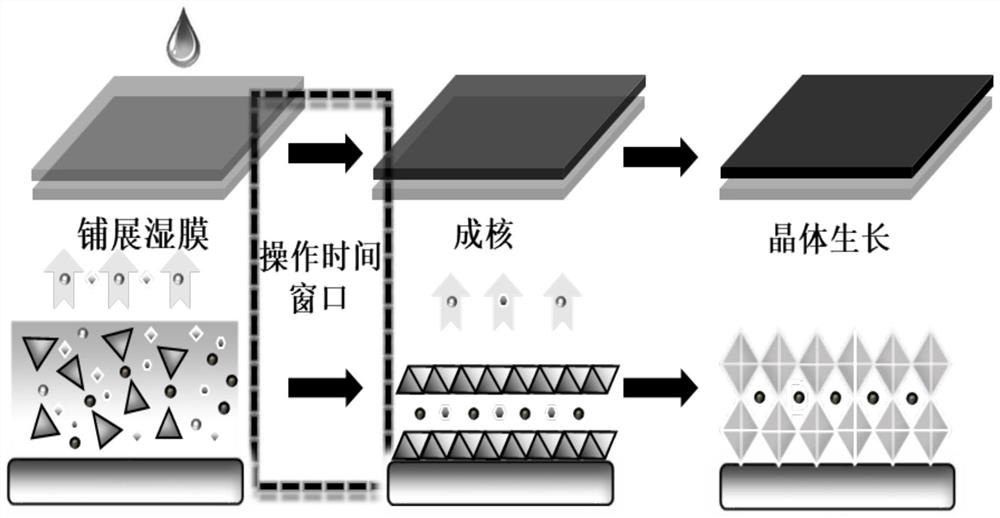

[0036] The method for preparing the above-mentioned perovskite solution, the preparation method comprises the following steps:

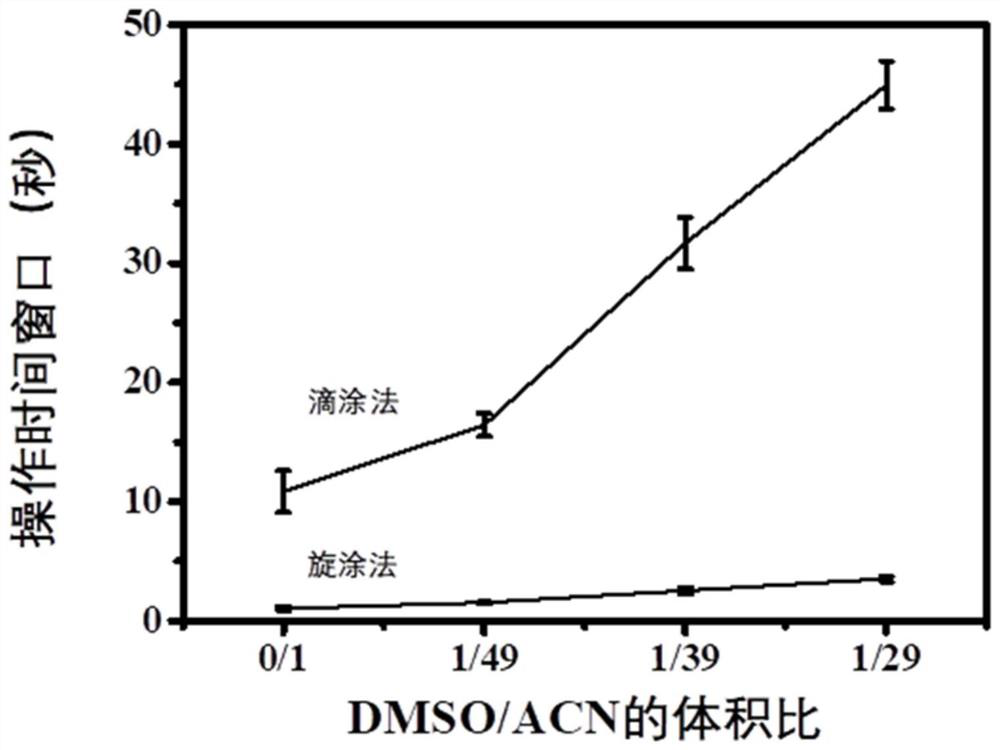

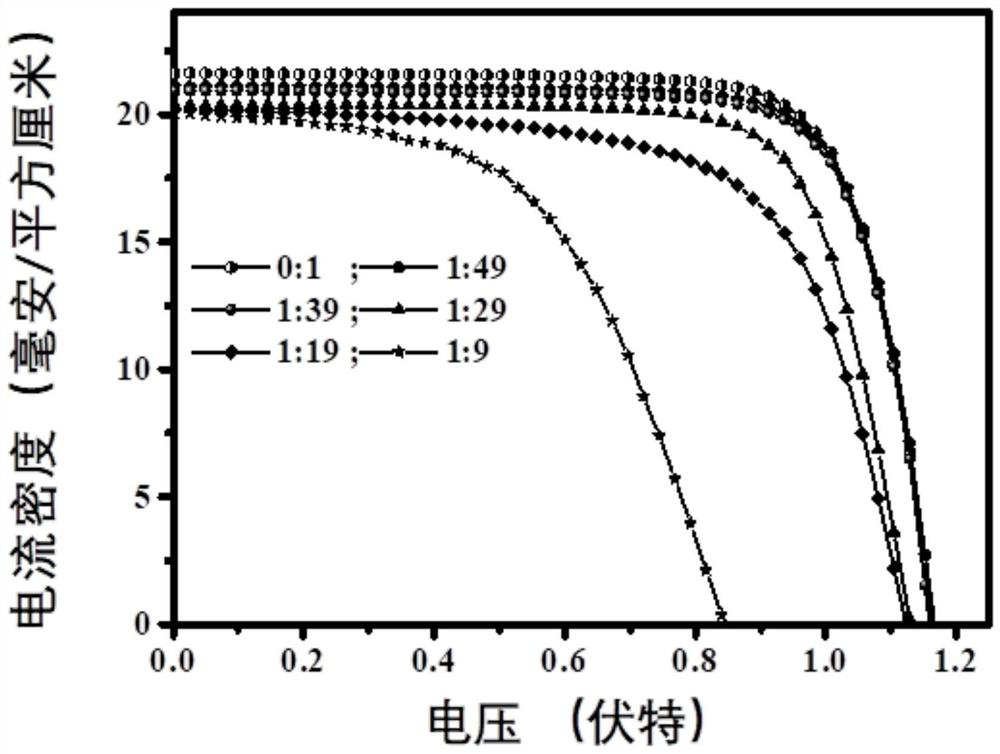

[0037] First, put the perovskite single crystal obtained by inversion temperature crystallization in advance or the methyl iodide and lead iodide powder prepared by stoichiometric ratio in a methylamine atmosphere to obtain a viscous yellow perovskite precursor solution, or Dissolve the perovskite single crystal obtained by inversion temperature crystallization in advance or the methyl iodide and lead iodide powder prepared by stoichiometric ratio in the solution of methylamine ethanol to obtain a viscous yellow perovskite precursor solution, and then, After using a coordination solvent and acetonitrile to mix evenly, dilute the perovskite precursor solution to obtain a perovskite ink, wherein the coordination solvent is selected from one or more of DMSO, NMP, and 4-TBP.

[0038] A method for preparing a gold electrode perovskite solar cell with a fi...

Embodiment 1

[0052] 1) Preparation of electron transport layer (dense layer)

[0053] Add 369ul of titanium tetraisopropoxide and 35ul of 2M hydrochloric acid solution into 5.06ml of absolute ethanol solution, and after stirring, apply it on a clean FTO conductive glass by spin coating, after 10min annealing temperature Relatively dense TiO is formed after 150°C 2 thin film with a thickness of about 30nm.

[0054] 2) Preparation of electron transport layer (mesoporous layer)

[0055] Dilute the 18-NRT titanium oxide mesoporous slurry with absolute ethanol to 15wt.%. After fully stirring the diluted solution for 5 hours, take 60ul spin coating on the film in step 1), and anneal at 80°C for 10 Minutes later, put it into a muffle furnace for calcination at 500 °C for 1 h, then cool to room temperature to form a layer of TiO 2 The mesoporous layer is about 100nm thick.

[0056] 3) Preparation of perovskite single crystal

[0057] PbI 2 Dissolve MAI powder in γ-GBL solution at a molar rat...

Embodiment 2

[0068] Embodiment 2 is different from embodiment 1 in that:

[0069] 1) In the preparation of the electron transport layer (dense layer), ITO conductive glass is used to form relatively dense ZnO 2 thin film with a thickness of about 50 nm.

[0070] 2) In the preparation of the electron transport layer (mesoporous layer), the final thickness obtained is about 140 nm.

[0071] 3) In the preparation of perovskite single crystal, MAPbCl was prepared 3 precursor solution.

[0072] 4) In the preparation of the perovskite ink, the mass concentration of methylamine ethanol was 41wt., put it into the ultrasonic machine for 1h until the solution became clear. Then add a mixed solution of 4-TBP and NMP with a certain volume ratio prepared according to actual deposition processing requirements. The perovskite ink with the corresponding processing time window is formulated after being fully mixed. The volume ratio of methylamine ethanol solution to acetonitrile is 1:0.8. The volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com