Composite coating for water electrolysis metal bipolar plate and preparation method thereof

A metal bipolar plate and composite coating technology, applied in the field of water electrolysis, can solve the problems of limiting the working efficiency of the electrolyzer and affecting the conductivity, etc., and achieve good passivation effect, prevent penetration, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

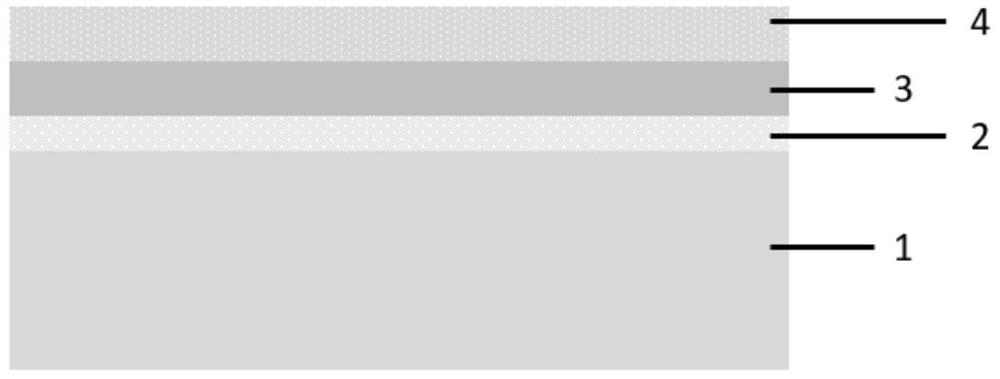

Image

Examples

Embodiment 1

[0031] TA1 type pure titanium was selected as the metal bipolar plate substrate, and the surface dust and oil stains were removed by ultrasonic cleaning in deionized water and ethanol in sequence, and then hung in the vacuum chamber of a magnetron sputtering coating machine after natural drying.

[0032] The chamber is evacuated to below 3 x 10 -3 Pa, keep the pressure at 0.5Pa by passing argon gas, apply -600V bias voltage to the sample for sputter cleaning for 10min, and remove the surface oxide film.

[0033] The pressure of the chamber was kept constant, and 30nm of titanium was deposited on the surface of the substrate as a self-healing layer by magnetron sputtering titanium target, the titanium target current was 5A, and the deposition time was 5min.

[0034] 18sccm nitrogen and 3sccm oxygen were introduced as reaction gases, the chamber pressure was adjusted to 0.7Pa, and 100nm of titanium oxynitride was deposited as a dense corrosion-resistant layer, wherein the number...

Embodiment 2

[0038] TA1 type pure titanium was selected as the metal bipolar plate substrate, and the surface dust and oil stains were removed by ultrasonic cleaning in deionized water and ethanol in sequence, and then hung in the vacuum chamber of a magnetron sputtering coating machine after natural drying.

[0039] The chamber is evacuated to below 3 x 10 -3 Pa, keep the pressure at 0.5Pa by passing argon gas, apply -600V bias voltage to the sample for sputter cleaning for 10min, and remove the surface oxide film.

[0040] The pressure of the chamber was kept constant, and 30nm of titanium was deposited on the surface of the substrate as a self-healing layer by magnetron sputtering titanium target, the titanium target current was 5A, and the deposition time was 5min.

[0041] 18sccm nitrogen and 4sccm oxygen were introduced as reaction gases, the chamber pressure was adjusted to 0.7Pa, and 100nm titanium oxynitride was deposited as a dense corrosion-resistant layer, wherein the proportio...

Embodiment 3

[0045] TA1 type pure titanium was selected as the metal bipolar plate substrate, and the surface dust and oil stains were removed by ultrasonic cleaning in deionized water and ethanol in sequence, and then hung in the vacuum chamber of a magnetron sputtering coating machine after natural drying.

[0046] The chamber is evacuated to below 3 x 10-3 Pa, keep the pressure at 0.5Pa by passing argon gas, apply -600V bias voltage to the sample for sputter cleaning for 10min, and remove the surface oxide film.

[0047] The pressure of the chamber was kept constant, and 30nm of titanium was deposited on the surface of the substrate as a self-healing layer by magnetron sputtering titanium target, the titanium target current was 5A, and the deposition time was 5min.

[0048] 18sccm nitrogen and 3sccm oxygen were introduced as reaction gases, the chamber pressure was adjusted to 0.7Pa, and 100am of titanium oxynitride was deposited as a dense corrosion-resistant layer, in which the number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com