Calcium sulfate reinforced in-situ curing pore-forming tissue engineering polyester composite scaffold material as well as preparation method and application thereof

A technology of polyester composite materials and polyester materials, applied in the field of bone repair materials, can solve problems such as excessive particle size and inconformity, and achieve the effect of promoting bone repair and improving biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The invention provides a kind of preparation method of calcium sulfate hemihydrate material, comprises the following steps:

[0073] a) After mixing calcium chloride, amino acid and water, a mixed solution is obtained;

[0074]b) After mixing the mixed solution obtained in the above steps, the Ca salt solution and the S salt solution again, the reaction is carried out to obtain a calcium sulfate hemihydrate material having a needle-like crystal structure.

[0075] In the present invention, calcium chloride, amino acid and water are firstly mixed to obtain a mixed liquid.

[0076] In the present invention, the content of calcium chloride in the mixed solution is preferably 0.001-5 mol / L, more preferably 0.01-4 mol / L, more preferably 0.1-3 mol / L, more preferably 1-2 mol / L.

[0077] In the present invention, the mass content of the amino acid in the mixed liquid is preferably 0.01-5%, more preferably 0.1-4%, more preferably 1-3%.

[0078] The present invention mixes the ...

Embodiment 1

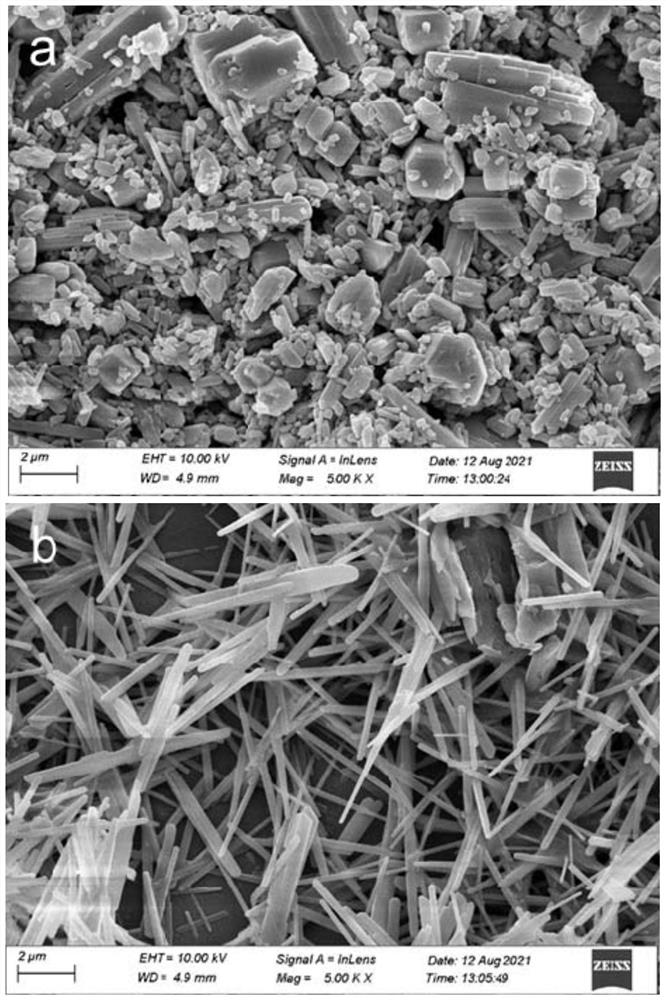

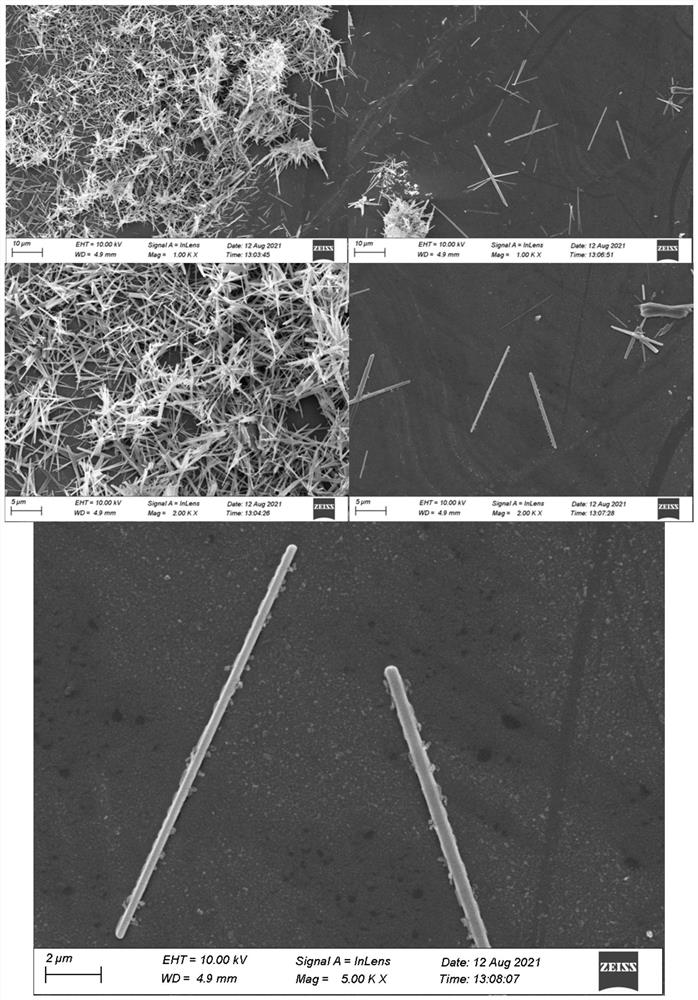

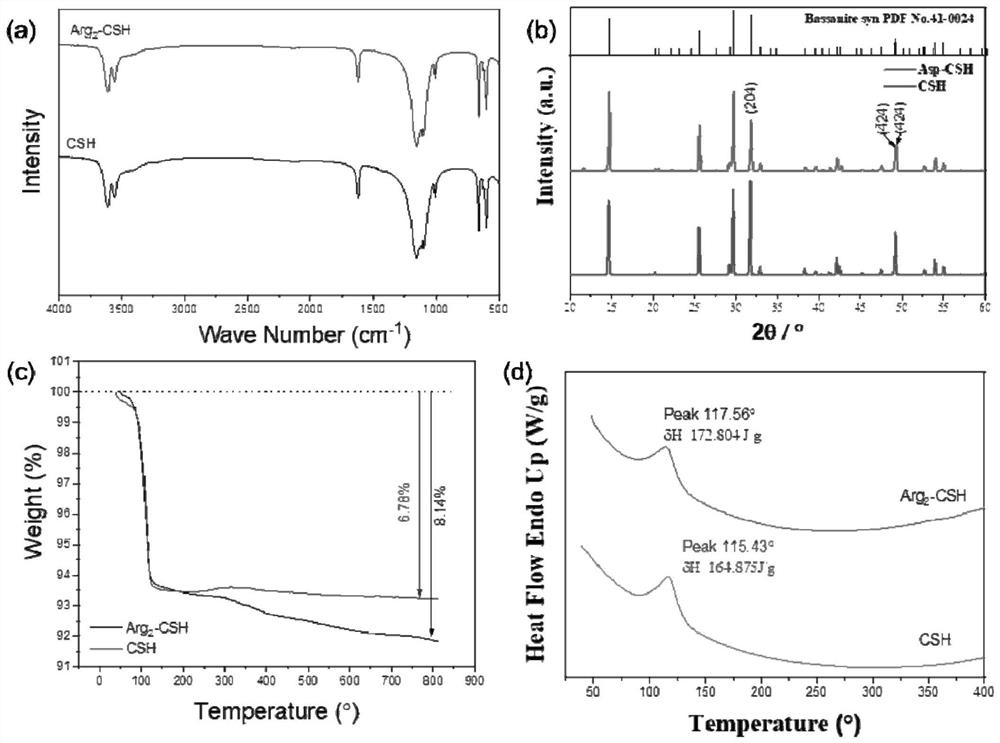

[0127] The present embodiment prepares amino acid modified calcium sulfate whisker:

[0128] Prepare 2 parts of 100 mL of CaCl 2 solution, where CaCl 2 The content is 3.5Mol / L, the content of aspartic acid is 2mg / mL, weigh 0.1mol Ca(NO 3 ) 2 4H 2 O and 0.1mol(NH 4 ) 2 SO 4 Add Ca salt solution and S salt solution to the above solutions respectively, then mix the above Ca salt solution and S salt solution, react at 105°C for 4 hours, filter with suction, wash the filter cake with hot water for 4 times, and soak the filter cake with absolute ethanol 3min to terminate the reaction, after suction filtration of absolute ethanol, the filter cake is placed in an 80°C blast drying oven to dry, and the product obtained is the calcium sulfate whisker (Arg 2 -CSH).

Embodiment 2

[0133] Preparation of amino acid modified calcium sulfate whisker reinforced polyester matrix composite scaffold:

[0134] Weigh 2.25 g of the obtained Arg-CSH and add it into 10 mL of N-methylpyrrolidone (NMP), and ultrasonically disperse for 2 hours until the dispersion is uniform. Weigh 1.5g PLGA into the above solution, stir overnight until the PLGA dissolves evenly to obtain a composite material slurry, pour the mixed solution into a self-made cylindrical polytetrafluoroethylene mold, and place it in a -80°C refrigerator for 1 hour. The slurry is solid, then quickly put it into deionized water for replacement, and change the water every 4 hours. After the solvent replacement is complete (4 days), a scaffold composite material Arg-CSH / PLGA with an Arg-CSH content of 60% is obtained for subsequent experiments. detection and characterization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap