Special lactobacillus inoculum for silage and its making method

The technology of lactic acid bacteria and inoculant is applied in the preservation method, bacteria and application of animal feed raw materials, which can solve the problems of high loss rate, high cost and high commodity cost, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

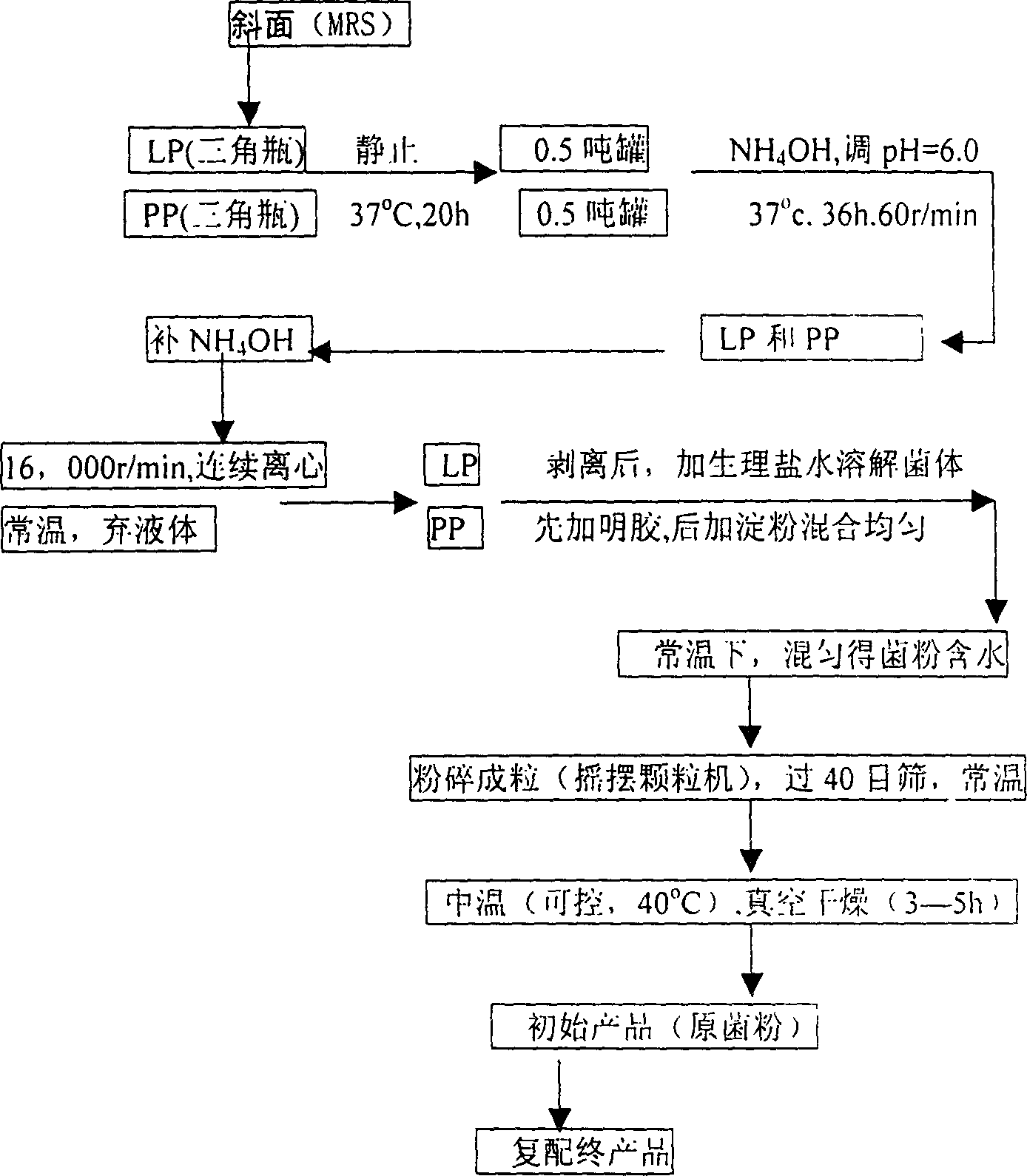

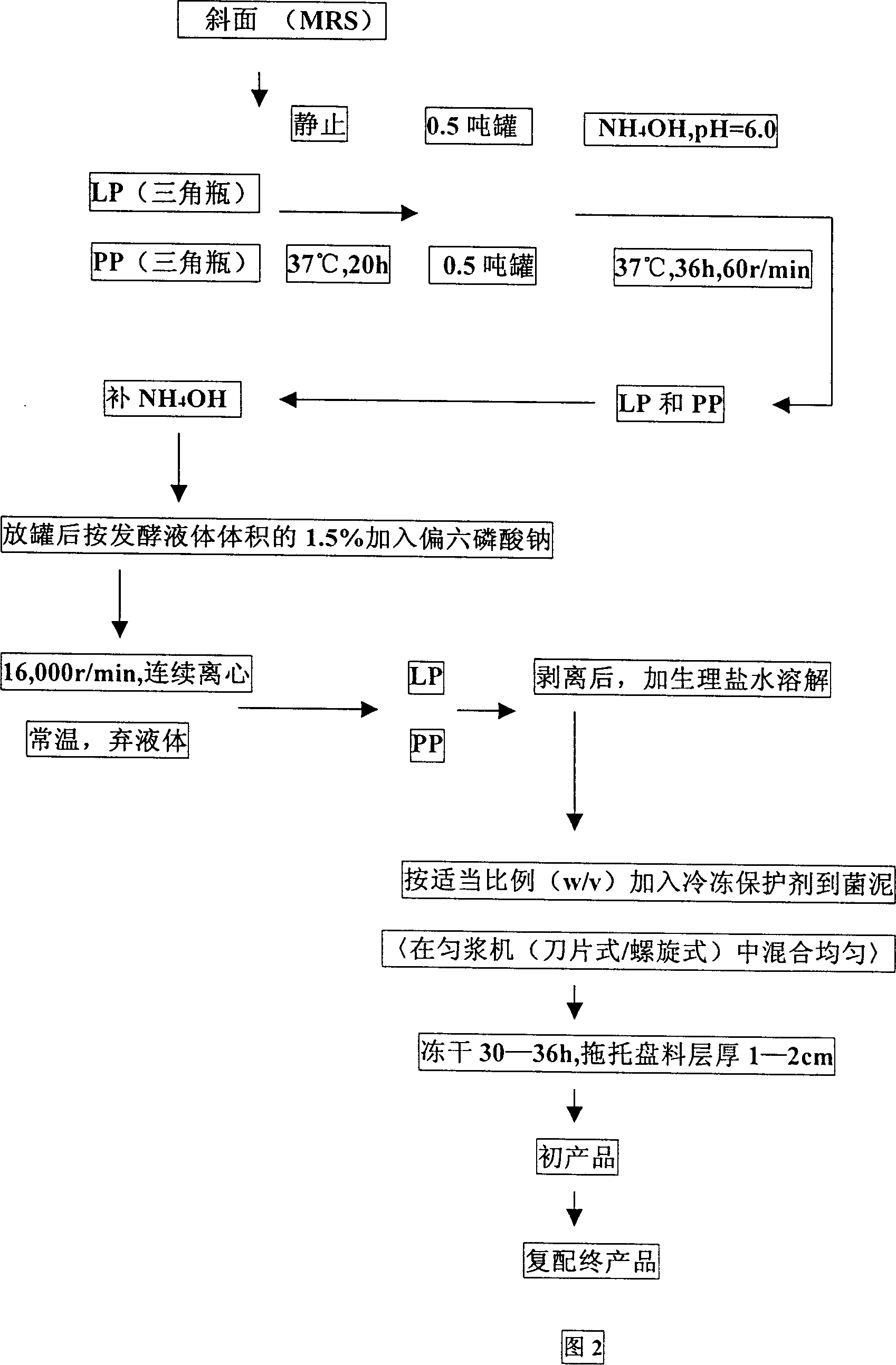

Method used

Image

Examples

Embodiment 2

[0057] Embodiment 2: product Lactobacillus plantarum of the present invention neutralizes Pediococcus pentosaceae count

[0058] 1. Medium

[0059] (1) 1% sterile peptone buffer solution: Accurately weigh 5 g of peptone and dissolve in 500 ml of deionized water, dispense into conical flasks, place in a sterilizer, sterilize at 121.5°C for 30 minutes, and set aside.

[0060] (2) MRS (Mgnn, Rogosa, Sharpe) medium composition and preparation (g / l): beef peptone 10g, yeast extract powder 5g, beef extract 10g, glucose 20g, Tween 80 1.0g, ammonium citrate 2.0g, acetic acid Sodium 5.0g, magnesium sulfate 0.1g, manganese sulfate 0.05g, dipotassium hydrogen phosphate 2.0g, deionized water 1000ML, pH=6.1-6.3, temperature 25°C. The pH of the medium was adjusted by ammonia water. According to the above formula, the reagent was weighed and dissolved in 1000ml deionized water, stirred and then packed in conical flasks. Then, sterilize at 121.5°C for 30-40 minutes, and when the temperature...

Embodiment 3

[0072] Embodiment 3, the influence of lactic acid bacteria inoculant of the present invention on corn silage quality and dairy cow production performance

[0073] 1. The silage inoculant of the present invention

[0074] The amount of silage used per ton is 10 grams, and the dry powdered inoculant is completely dissolved in water according to the ratio of 5 grams per liter, and then the SIB-HA inoculant is sprayed into the silo with a motorized knapsack sprayer. On the crushed silage layer, after each layer of silage is laid, the inoculant solution is sprayed once, compacted back and forth with a crawler tractor, and other links are treated according to conventional silage measures, which will be used for the feeding test of dairy cows in the next year.

[0075] 2. Silage quality assessment

[0076] Fresh whole-plant corn (spring corn variety Zhongyu No. 4) was chopped with a cutting machine at a dairy farm in the northern suburbs of Beijing, and the length was less than 50 mm....

Embodiment 4

[0096] The test of embodiment 4 dairy cow production performance

[0097] During the first 30 days of the experiment, the silage of the SIB-HA treatment group and the control silage had no effect on the milk production of dairy cows. After 30 days, the effects of treated silage and control silage on milk production of cows began to be evident. The results of the dairy cow feeding experiment showed that the daily milk yield of dairy cows was 0.9kg / head higher than that of the control under the treatment of SIB-HA. As a result, the annual milk production increased by 283 kg / head (the average lactation period was 305 days). In addition, based on the average daily intake of 20 kg of silage per cow, 1 ton of silage corn treated with SIB-HA can increase the milk yield by 46.5 kg due to the improvement of quality. This study also observed improved milk production in cows fed SIB-HA-treated corn silage for 30 days. Apparently, although the milk quality was not significantly improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com