Novel therapeutic uses of glucan

a technology of glucan and glucan, which is applied in the field of new therapeutic uses of glucan, can solve the problems of poor yield, disadvantageous prior art methods for the production of microparticulate glucan in one or more respects, and less than 5% w/w

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

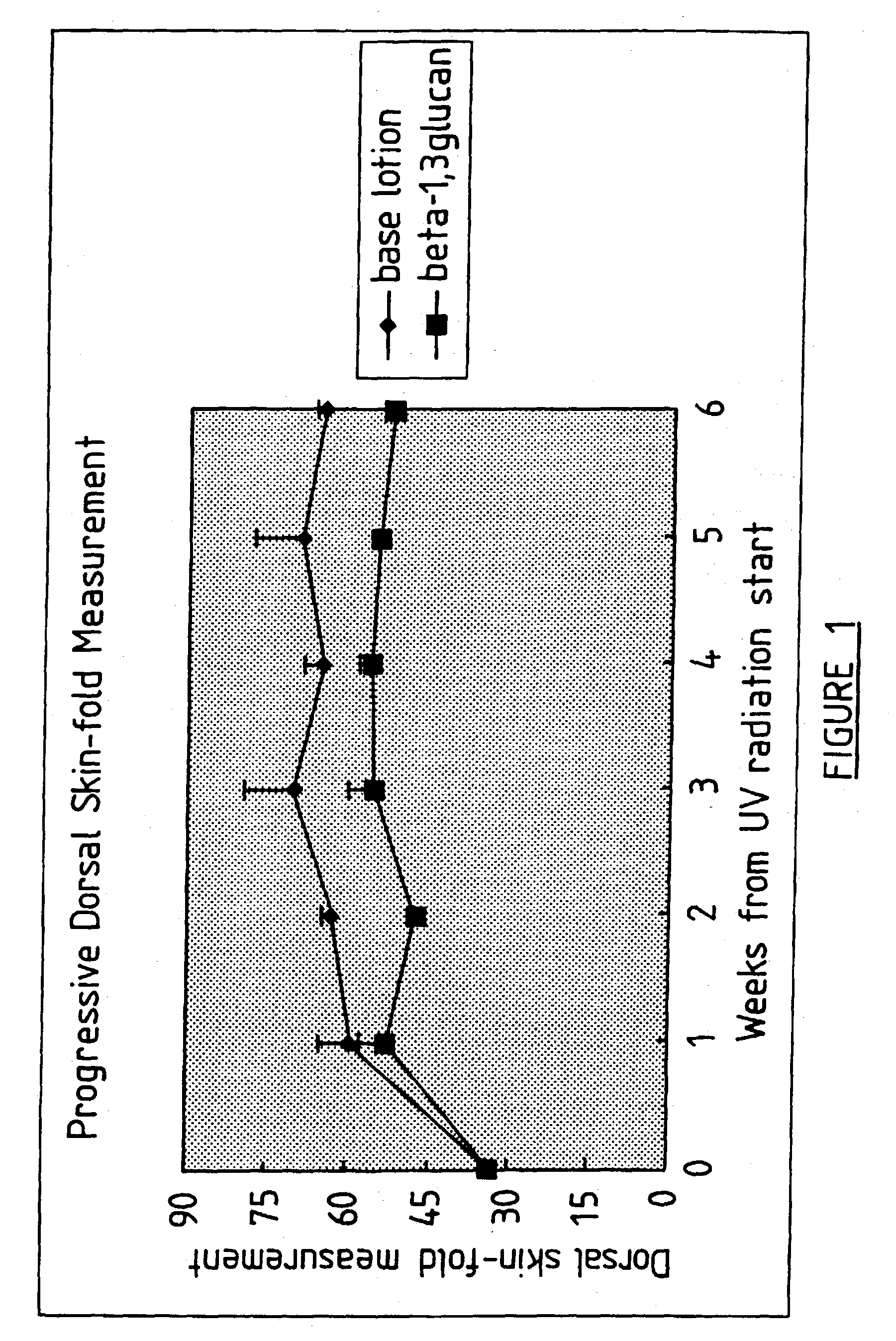

Image

Examples

example 2

[0138] Microparticulate Sc-glucan is prepared as follows:

[0139] A 400 g sample of commercial Saccharonzyces cerevisiae in dry form is added to four litres of 4% w / w sodium hydroxide and heated to 100.degree. C. for one hour with vigorous stirring. The suspension is allowed to cool to between 45.degree. C. and 50.degree. C. before the lysed yeast cells are separated from the alkaline hydrolysate by centrifugation at 800 g for ten minutes. The lysed yeast cells are resuspended in a fresh batch of three litres of 3% w / v sodium hydroxide and boiled for 15 minutes. Following separation by centrifugation, the lysed yeast cells are resuspended in a fresh batch of two litres of 3% w / v sodium hydroxide and boiled for 15 minutes followed by standing at 70.degree. C. for 16 hours. Following separation by centrifugation, the lysed yeast cells are resuspended in water and boiled for 10 minutes. The latter step is repeated once. Following centrifugation, the lysed yeast cells are resusended in a ...

example 3

[0142] A protocol for the preparation of minimally-polymerised, soluble Sc-glucan according to the present invention is as follows.

[0143] Microparticulate Sc-glucan is produced as detailed in Example 2. Ten g of this material is suspended in 100 mL sterile 5% NaOH solution and stirred gently for two hours at 5.degree. C. (giving a pH around pH 13). The suspension then is diluted 1:1 in sterile, distilled water and then filtered through a 1 u membrane to remove undissolved particulate material. The pH of the filtered solution then is adjusted to 10 by the addition of 5M HCl and then dialysed against 2 L distilled water (pH 10) in a Pelicon system using a 10,000 D limiting membrane. The solution then can be sterilised by passage through a 0.45.mu. membrane and the pH of the solution may be adjusted as desired. The soluble glucan so produced is useful as a pharmaceutical product.

[0144] Gel permeation chromatography (Waters Styragel HR 5.RTM. column; effective molecular weight range of ...

example 4

[0145] A protocol for the preparation of polymerised, soluble glucan according to the present invention is as follows.

[0146] Microparticulate Sc-glucan is produced as detailed in Example 2. Fifteen g of this material is suspended in 100 mL sterile 5% NaOH solution and stirred gently for two hours at 5.degree. C. The suspension then is centrifuged at 1000 g to remove undissolved particulate material. The pH of the solution then is adjusted to 10 by the addition of 5M HCl and then dialysed against 2 L distilled water (pH 10) in a Pelicon system using a 10,000 D limiting membrane. The pH then is adjusted to 7.5 by the further addition of hydrochloric acid producing a viscous gel which is useful as a pharmaceutical product.

[0147] Gel permeation chromatography showed the material was essentially homogenous with a very narrow molecular weight spread, having an average molecular weight of 320,000 daltons and a polydispersity index of 2.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com