Screening and application of beer microzyme containing CMP kinase and CDP kinase

A technology of brewer's yeast and brewer's yeast, which is applied in the field of bioengineering, can solve the problems of high enzyme inactivation rate, inability to completely separate the glycolysis system, and low conversion rate, and achieve high purity, stable process, and long maintenance time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

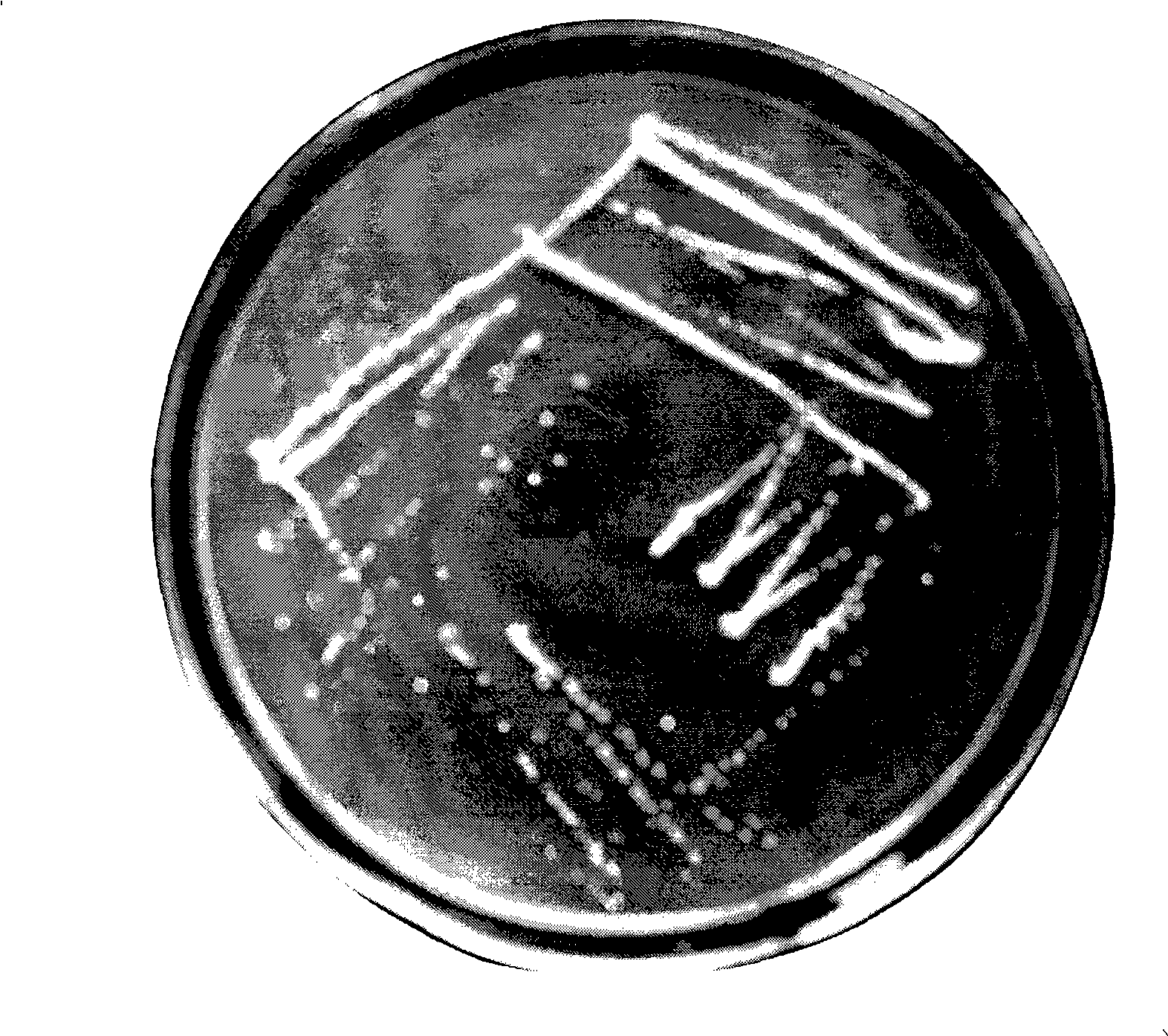

[0032] (1) After the commercially available brewer's yeast to be screened is activated on a slant medium, it is transferred to a shaking table for culture. The temperature of the shaking table is 30°C and the rotation speed is 200rpm. Bed culture to the logarithmic growth phase, centrifuge to recover the bacteria, add 5ml of phosphate buffer solution with pH 7.0 to make the bacteria suspension.

[0033] (2) Weigh 20mg of NTG, dissolve it in acetone, add distilled water to 10ml, which is 2mg / ml NTG solution, mix 1ml of bacterial suspension with 1ml of nitrosoguanidine (NTG) solution, shake and mix Afterwards, bathe in a constant temperature water bath at 30°C for 30 minutes, and then dilute the mixture to 10 -3 Stop mutagenesis. After the mutagenesis was terminated, the stop solution was diluted to 10 -5 、10 -6 Afterwards, cytidine diphosphate-ethanolamine (300 μg / ml) plates were coated with the structural analogue of cytidine triphosphate, and cytidine diphosphate-ethanolam...

Embodiment 2

[0036] (1) Weigh 200g of κ-carrageenan sodium salt, 100g of refined konjac powder, dissolve in 5L of deionized water, heat to 121°C with steam, keep warm for 60min, pour it into a 20L reactor with stirring, and let it cool naturally to 40 °C, keep the glue solution warm for later use.

[0037] (2) Weigh 4 kg of washed beer yeast wet cells and add 1 kg of physiological saline, stir evenly, and keep warm at 35°C for later use.

[0038] (3) Pour the insulated yeast suspension into the glue, stir at 40°C for half an hour to mix evenly, and set aside.

[0039] (4) Add 60L soybean oil into a 100L stirred reactor, preheat to 40°C, control the stirring speed at 125rpm, pour the mixture of yeast and glue into the soybean oil, stir for half an hour until the particles are formed, filter, and the soybean oil After recovery, let it stand still, and discard the water in the lower layer, and then reuse it.

[0040] (5) Soak the particles filtered in step (4) for one hour with 3% potassium...

Embodiment 3

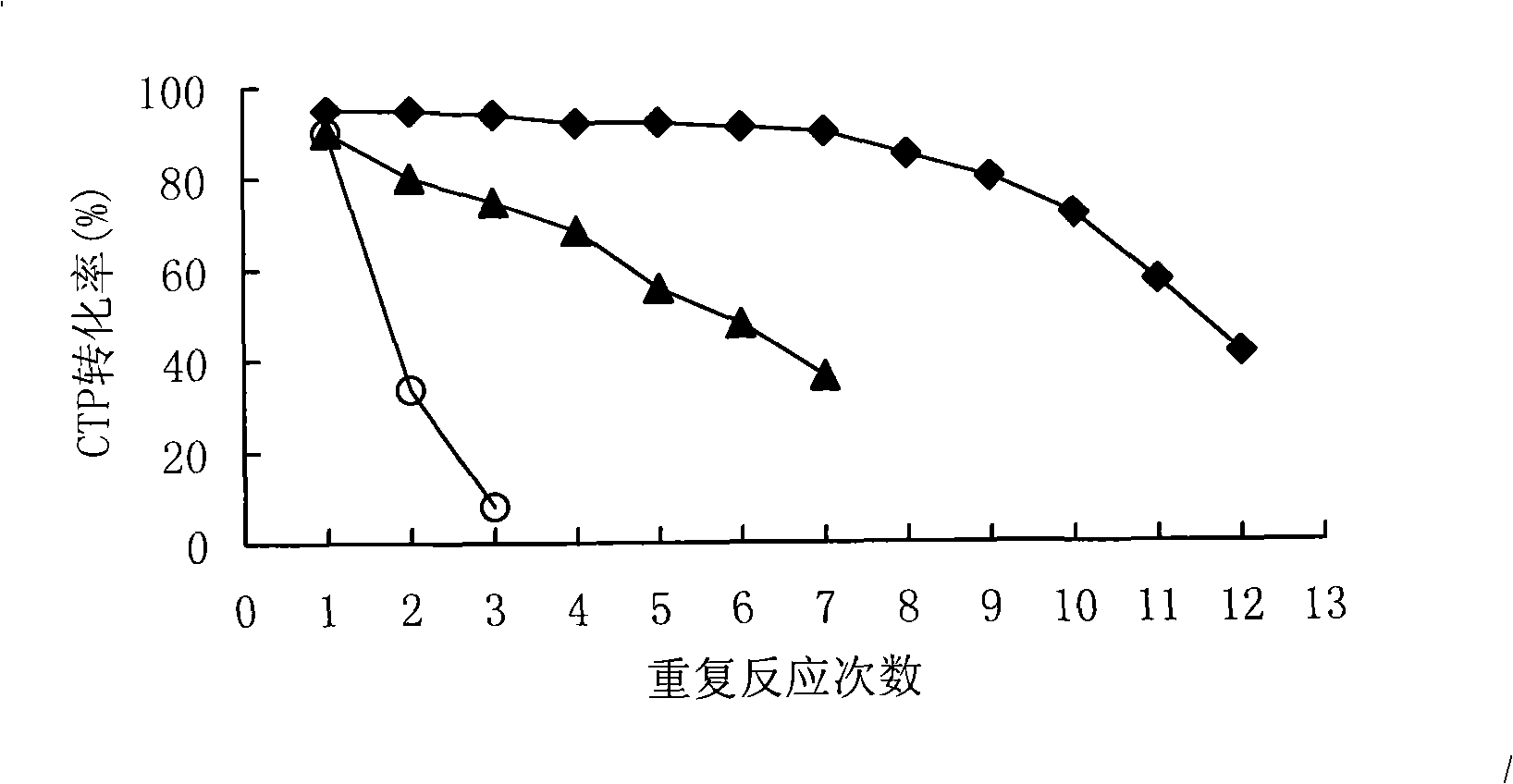

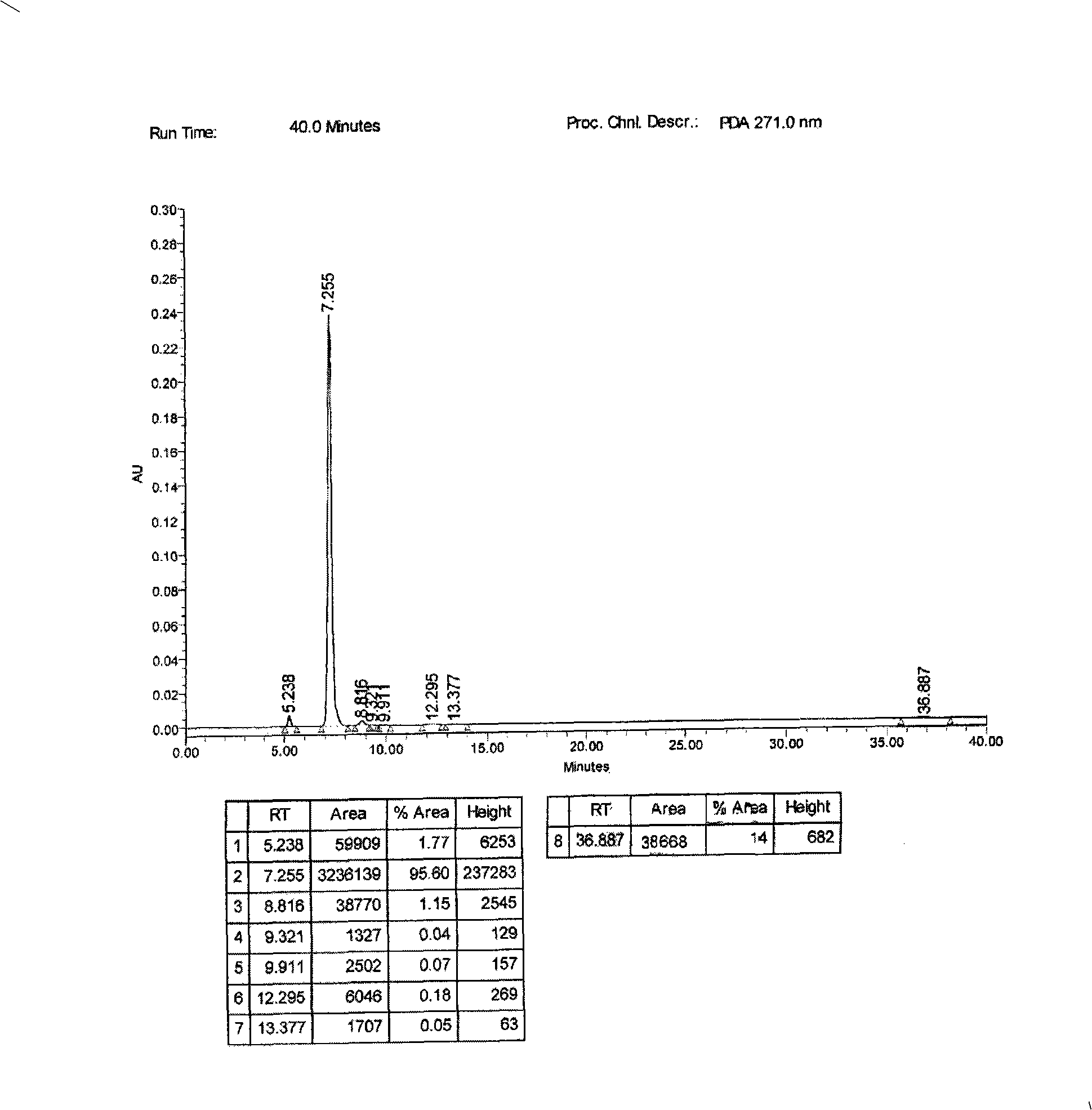

[0053] In the reaction system for the synthesis of CTP by immobilized yeast, in addition to generating a large amount of CTP, there are also impurities such as unreacted CMP and by-product CDP, phosphate, etc. In order to separate CTP from the reaction solution, HZ-1 ion exchange resin is used for Ion exchange chromatography, and use 0.4mol / L sodium chloride first, and then use 1.0mol / L sodium chloride solution to carry out gradient elution with a column volume of 0.2-0.5 per hour. Concentrate the eluent under reduced pressure in a water bath at 50-60°C, add 3 times the volume of 95% ethanol, let it stand overnight in the refrigerator, filter it with suction, and dry the filter cake. The finished product is detected by high-performance liquid chromatography. Chromatographic conditions and implementation Example 1 is the same. For the continuous response of immobilized yeast to CTP, see figure 2 , it can be seen from the figure that more than ten batches of immobilized spheri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com